O&M

-

O&M

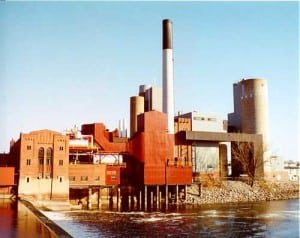

Case Histories: Co-Firing Coal and Oat Hulls Reduces Emissions at University Power Plant

The University of Iowa (UI) Biomass Fuel Project has produced significant reductions in greenhouse gas emissions, regulated boiler stack emissions, and purchased energy costs. The project utilizes a renewable, biomass fuel source and provides an opportunity for UI to partner with a local industry. UI was approached by Quaker Oats Co., Cedar Rapids Facility in […]

-

O&M

Case Histories: Asheville Power Station’s Retrofit First to Meet North Carolina’s Clean Smokestacks Act

Asheville Power Station’s Unit 1 in Arden, North Carolina, was the first coal-fired unit to be modified with a flue gas desulphurization (FGD) system and placed in service to meet the clean air requirements of the state’s Clean Smokestacks Act. As of November 16, 2005, at least 97% of the sulfur dioxide that had been […]

-

O&M

Case Histories: Synthetic Oil and Enhanced Filtration Reduce Wear and Extend Gear Life

A coal-fired power plant operating in the western U.S. was experiencing short gearbox life in its coal-pulverizing operation. After an annual gearbox inspection, oil analysis results indicated that the AGMA 6EP (ISO 320) gear oil recommended by the original equipment manufacturer (OEM) had failed to provide adequate lubrication and protection. This conclusion was based on […]

-

O&M

Profiling your plant engineering staff

The latest benchmarking study by the EUCG examines the engineering and technical staffing of 62 plants, 92% of which burn coal. If you benchmark your units, plants, or fleet, the results may raise some eyebrows. But they also may help justify your plea for more intellectual capital during the upcoming budgeting cycle. Though the detailed results of the study are proprietary to EUCG member companies that participated in it, POWER was given access to the complete findings. If you want details at the plant/unit level, you’ll have to join the EUCG and participate in the study, which is ongoing.

-

O&M

Focus on O&M (July/August 2006)

Safer, "virtual" reactor walkdowns; Beating the heat with inlet cooling; Reaching remote substations without fiber; One-year payback for lightning protection systems; Reaching remote substations without fiber

-

O&M

Mergers present challenges—and opportunities—for plant managers

The sale or merger of any company takes its toll on employees. Though it’s merely a hassle adapting to a different T&E form, the sudden uncertainty about health-care coverage and pension can be truly stressful. For plant managers, the impact is even greater—adapting to a new budgeting process and reporting requirements, not to mention answering hundreds of subordinates’ questions about the future, even before the deal closes. However, plant managers may actually end up better off as a result of a merger or acquisition.

-

O&M

Computer-based hydro plant scheduling

Hydroelectric power plant managers face unique scheduling challenges. They have a finite amount of water in their reservoirs available for energy production, and they need to schedule generation according to market demand to maximize profits from their limited “fuel” supply. Hydro power plants are capable of producing products other than electricity. Among them are ancillary […]

-

O&M

Monitor your fluid levels online

Although fluid monitoring technology has come of age in recent years, its level of sophistication varies widely across industries. Some users of bulk chemicals, fuels, and other fluids use state-of-the-art systems with bells and whistles like automated data gathering and transmission. At the other extreme, some tank farms still “stick the tanks.” Although 95% of large […]

-

O&M

Standardizing PdM, fleetwide

The pressure on power producers to supply reliable electricity is unyielding. Forced outages, which usually are caused by unexpected component failure or systemic problems, can prove very costly to both bottom line and reputation. To reduce the frequency and duration of unscheduled outages, many gencos are implementing comprehensive predictive maintenance (PdM) programs. Such is the […]

-

O&M

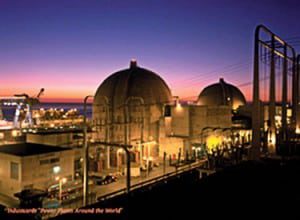

Improving the reliability of turbine lube oil supply

Five years ago, San Onofre Nuclear Generating Station’s Unit 3 turbine experienced substantial damage after the supply of oil to its bearings failed. Because the turbine coasted down without oil after it tripped, its bearings, journals, and steam path needed extensive repairs. A follow-up investigation revealed lube oil system vulnerabilities that were subsequently corrected. The lessons learned might also improve your turbine-generators’ lube oil reliability, saving you many millions in lost revenues.