O&M

-

O&M

Flue Gas Analysis as a Furnace Diagnostic Tool

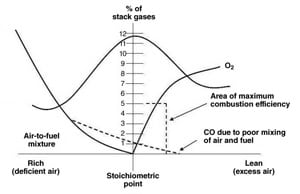

Combustion flue gas analysis has been used to optimize the boiler air/fuel ratio for decades. Measuring the amount of excess oxygen and/or carbon monoxide in combustion flue gases gives an indication of boiler efficiency and, thereby, plant operating economics. New sensors make those measurements simple and accurate.

-

O&M

Keeping Condensers Clean

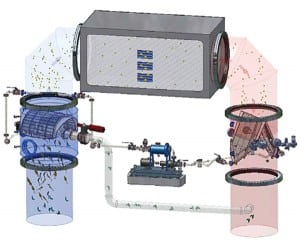

The quality of the cooling water intake and the amount of debris in that water affects the operation and performance of the condenser and therefore the thermal performance of the typical steam plant.

-

O&M

Expanding the Use of Predictive Maintenance as a Business Strategy

The Linde Group is a world-leading gases and engineering company operating in more than 100 countries. It’s no surprise that the company uses a variety of advanced monitoring techniques and equipment to keep its plants operating reliably. In the U.S. and UK particularly, Linde plants have used online machine condition monitoring for a number of years. At its Shanghai headquarters, Linde has formed a large and impressive remote operations center where it monitors and tracks the process operations of all its major gas plants in China 24 hours a day.

-

O&M

Power 101: Improving the Performance of Boiler Auxiliaries, Part I

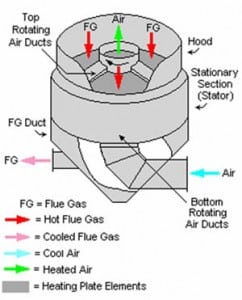

Boiler auxiliary equipment often receives no respect for the role it plays in maintaining efficient boiler performance. In this second installment of our Power 101 series, we examine the design and performance of the air preheater.

-

O&M

CSB Releases Hot Work Safety Notice

The Chemical Safety Board (CSB)—an independent federal agency charged with investigating serious chemical accidents such as equipment failure, as well as inadequacies in regulations, industry standards, and safety management systems—recently released multiple reports that should be made part of every power plant’s safety training program.

-

O&M

NFPA Gas Purging Rules Updated

The CSB has made urgent recommendations to the NFPA and the International Code Council to prohibit indoor purging and require companies and installers to purge flammable fuel gases to safe locations outdoors, away from workers and ignition sources.

-

O&M

Abrasion-Resistant Pipe Handles Ash Slurry

Steel piping systems are widely used at coal-fired power plants for a variety of purposes, including the conveying of coal ash slurry to nearby settling ponds, the transfer of limestone slurry to absorber spray towers for removal of SO2 and dilute hydrochloric acid from flue gases, and for transporting away the calcium sulfate by-product of the flue gas desulfurization process.

-

O&M

Air Casters Speed Equipment Moves

When it comes to moving megaton items like feedwater heaters or recirculating pumps, conventional moving tools such as wheel rollers, cranes, hoists, and come-alongs may be virtually useless. In some cases, moving large components is dangerous in a space-constrained location surrounded by delicate process control equipment. Feedwater heater and recirculating pump removal and replacement are […]

-

O&M

Retrofitting BWR Recirculation Pumps with Adjustable-Speed Drives

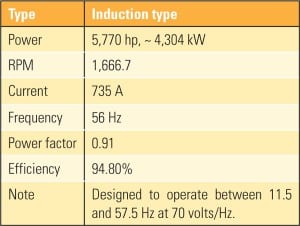

Exelon Nuclear recently replaced the original motor-generator sets for its boiling water reactor (BWR) recirculation pumps at its Quad Cities Generating Station Unit 1 with adjustable-speed drives. We examine the actual energy savings, motor-starting characteristics, control accuracy and stability, and motor and cable thermal behavior of this retrofit project.

-

O&M

Pulverized Coal Pipe Testing and Balancing

If you want the most accurate test results, it’s worth the extra effort to take isokinetic coal samples from coal pipes when collecting fuel and air measurements. Together, the data collected will allow more accurate balancing of coal pipes, measure fuel fineness, and improve the combustion efficiency of your steam generator.