O&M

-

O&M

Real-time Proactive Safety in Construction

For each of the past 10 years, nearly 1,200 U.S. construction workers have died as the result of injuries received on the job. Of these fatalities, 25% involved heavy equipment—most categorized as struck-by incidents. Remote sensing and visualization technology promises to improve worker situational awareness on congested and busy work sites.

-

O&M

Microns Matter: Proper Design of Fogging Nozzles

Inlet fogging systems for combustion turbines achieve their effect at the molecular level: The cooling effect occurs by converting thousands of gallons of water into single evaporated molecules suspended in the air. The right fog pattern comes down to a matter of selecting the best nozzle design and proper placement in the inlet air stream.

-

O&M

Using Temperature- Measuring Indicators

Correct welding procedures are extremely important elements of the work done by the PSEG Central Maintenance Shop (serving Public Service Electric and Gas Co., PSEG, a New Jersey utility). We have, for example, a Critical Weld Inspection Program for high-temperature pressure piping whose goal is to identify cracks in high-temperature piping welds.

-

O&M

Wet Booster Fans Optimize Power Station Performance with FGD and Wet Stack

A Romanian lignite-fired power station wanted to minimize the operating cost of the flue gas desulfurization (FGD) system by placing the booster fans in the "wet position," between the wet FGD scrubber and the wet stack, where they would consume significantly less power. A number of combined environmental effects must be considered in this design.

-

O&M

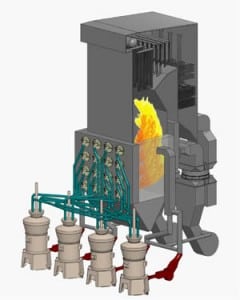

Pulverizers 101: Part III

Pulverizers prepare raw fuel for burning by grinding it to a desired fineness and mixing it with the just the right amount of air before sending the mixture to boiler burners for combustion. Part I of this three-part report examined the essentials of pulverizer design and performance; Part II discussed the importance of fuel fineness. This final article discusses the importance of air and fuel measurement.

-

O&M

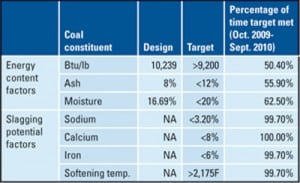

Improved Performance from Priority-Based Intelligent Sootblower Systems

When sootblower operation frequency is too high, a plant risks losing power generation from tube leaks; but when sootblower frequency is too low, there is a risk of boiler pluggage. Intelligent sootblowing finds the right balance between tube erosion and plant economic operation.

-

O&M

Tools at Height

A structure or mechanical system that requires fasteners also demands tools to maintain it properly. In power sectors such as wind, fossil fuel, and nuclear, some work areas may be several hundred feet in the air. While working at those extreme heights, or even just 10 feet off the ground, it’s simply unacceptable to drop anything. That’s why the concept of “tools at height” is being embraced as a way to improve safety and efficiency on the worksite.

-

O&M

Steam Turbine Cleaning Using Chemical Foams

In the May issue, we discussed the importance of either preventing copper plating of the high-pressure (HP) steam turbine rotor or finding a good foam or mechanical removal means of restoring lost efficiency. In that article we noted that “copper deposits typically form on the stationary nozzle block or first-stage stationary blades” and that those deposits usually result in a steam turbine loss of capacity at a rate of about 2 to 3 MW per month. We also stated that the “general rule of thumb is that there is a reduction of about 1 MW of generating capacity for each 1 to 2 pounds of deposit that accumulates on the HP turbine.

-

O&M

Predictive Maintenance That Works

This is the fourth in a series of predictive maintenance (PdM) articles that began in the April “Focus on O&M” with an introduction to PdM as a process whereby maintenance is performed based on the condition of the equipment rather than on a predetermined interval. In the May and July issues, we began exploring specific PdM techniques, such as motor-current signature analysis and oil analysis.

-

O&M

Optimizing Condenser Tube Selection

Selecting the most economical tube for a new condenser, or the retrofit of an existing one, is much more complex than mere price shopping. Each material has unique performance characteristics that affect the operating economics of the entire plant. A case study illustrates the importance of carefully choosing the tube material that is right for your plant.