Instrumentation & Controls

-

Instrumentation & Controls

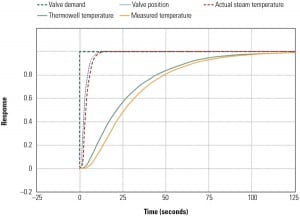

Thermocouple Response Time Study for Steam Temperature Control

One important factor in power plant control system performance is the response time of the process measurement used in the control system. The response time of boiler steam temperature sensors and thermowells is examined, as is those sensors’ and thermowells’ effect on desuperheater temperature response time and, therefore, steam temperature control performance.

-

Instrumentation & Controls

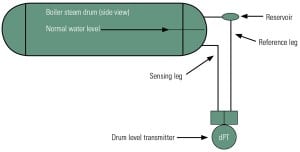

Concerns About Temperature-Equalizing Columns Used for Steam Drum Level Measurement

In the 1950s, temperature-equalizing columns were commonly used in steam drum differential pressure–based devices for measuring water level. However, these columns are problematic because a portion of the reference leg can flash to steam on a pressure decrease (load increase), and this will result in a temporary, false, high-level measurement, which adds to the swell effect. The columns can also result in measurement inaccuracies. It’s time to replace these antiquated instruments with a more modern reference leg.

-

Coal

Luminant’s Oak Grove Power Plant Earns POWER’s Highest Honor

Luminant used remnants of the ill-fated Twin Oaks and Forest Grove plants (which were mothballed more than 30 years ago) to build the new two-unit 1,600-MW Oak Grove Plant. Though outfitted with equipment from those old plants, Oak Grove also sports an array of modern air quality control equipment and is the nation’s first 100% lignite-fired plant to adopt selective catalytic reduction for NOx control and activated carbon sorbent injection technology to remove mercury. For melding two different steam generators into a single project, adopting a unique and efficient “push-pull” fuel delivery system, assembling a tightly integrated team that completed the project on time and within budget, and for completing what was started almost four decades ago, Oak Grove Power Plant is awarded POWER magazine’s 2010 Plant of the Year award.

-

Nuclear

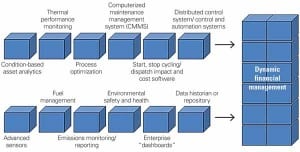

The Value of a Knowledge-Based Culture Grows in Lean Times

Given delays and cancellations of new generating capacity, pushing the existing power generation fleet is more important than ever. At ELECTRIC POWER 2009, multiple presentations explored the premise that an active knowledge management strategy — requiring a blend of digital and human elements unique to each power plant — will help you extract the most productivity from your assets.

-

O&M

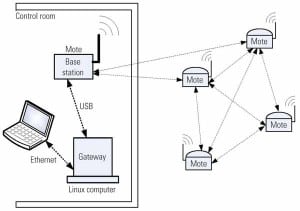

Low-Cost Wireless Sensors Can Improve Monitoring in Fossil-Fueled Power Plants

As equipment ages in fossil-fueled power plants, component wear leading to machinery failure increases as a result. Extending equipment life requires increased attention to maintenance, and one way to improve maintenance planning is to detect faults prior to failure so maintenance can be scheduled at the most cost-effective, opportune time. This type of strategy benefits from the use of additional sensors, and wireless ones can often be installed with the least time and cost.

-

O&M

How to Avoid Alarm Overload with Centralized Alarm Management

In 1999, the Engineering Equipment and Materials Users’ Association (EEMUA) released its general guide to the design, management, and procurement of alarm systems for industrial plants. The guidance document (EEMUA 191), however, is vague about applications to specific facilities, such as electric power plants. This article specifies EEMUA 191 standards and practices applicable to the electric power industry and spells out specific variations in alarming practices that are tailored for today’s power plants.

-

Nuclear

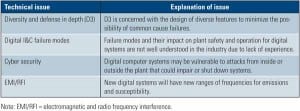

Nontechnical Issues Affecting Digital Upgrades at Nuclear Power Plants

Existing nuclear power plants are increasingly facing the conversion to digital instrumentation and controls technology. Meanwhile, new nuclear designs have digital technology integrated throughout the plant. Digital controls will soon be inevitable, so how do we make the transition as smooth as possible? Without losing focus on the technical solutions, organizations have to pay attention to the nontechnical issues as well.

-

Coal

Digital Plant Controls Provide an Essential Edge

It’s a digital world, and even aging power plants are experiencing the benefits of digital controls technologies. The following cover stories provide insight into the latest options and inspiration for your own plant controls projects.

-

Nuclear

Concerns About Electromagnetic Interference in Nuclear Plants Related to Digital Upgrades

In order to operate aging nuclear power plant instrumentation and control systems for up to 60 more years or longer, there must be a smooth transition from existing analog technologies to advanced digital platforms. For this to occur, electromagnetic compatibility concerns related to both qualification testing and the electromagnetic environment must be addressed to ensure safe and reliable operation of these systems within the plant’s electromagnetic and radio frequency interference environment. By understanding the regulatory requirements and sharing implementation experience, digital system upgrades can be installed successfully.

-

Nuclear

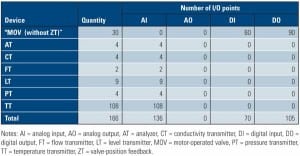

The Advanced Digital Fieldbus Option for Nuclear Plants

Digital fieldbus technologies, including Foundation fieldbus and Profibus, are increasingly being used with success in the nuclear and fossil fuel power industries. This article compares a conventional control system with a Foundation fieldbus – based digital control system used in a typical circulating water system in a nuclear power plant. As shown in this example, using digital fieldbus technologies can result in significant savings in terms of installation and hardware costs.