Instrumentation & Controls

-

O&M

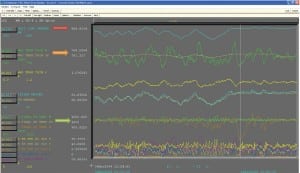

Increasing Generation Ramp Rate at Morgantown Generating Station’s Coal-Fired Units

At Morgantown Generating Station, plant personnel used innovative methods to combine model predictive control with distributed control system–based process control algorithms to improve waterwall temperature control and main steam temperature control and to enhance unit ramp rate capability. The previous heat rate and NOx optimization performance gains were retained. Focusing beyond basic loops of feedwater, air, and O2, the project considered issues such as PID controller override configuration and limitations. The techniques used to overcome these challenges improved unit ramp rate capability beyond any previous unit performance.

-

Nuclear

I&C Update on Plant Vogtle Units 3 and 4

Development of Vogtle Electric Generating Station Units 3 and 4—the first new nuclear power plant units in the U.S. in decades—has generated considerable excitement. The next generation of nuclear plants, represented by these units, includes at least two major improvements: the use of passive safety systems and a reliance on digital control systems. The latter represents a gigantic leap in modernization and a fundamental change in control of the plant.

-

O&M

New Tools for Diagnosing and Troubleshooting Power Plant Equipment Faults

The Electric Power Research Institute has developed a pair of diagnostic tools that combine and integrate features from multiple sources of plant information. The Diagnostic Advisor and the Asset Fault Signature Database will improve diagnostics for and troubleshooting of equipment faults by providing a holistic view of the condition of plant equipment.

-

Gas

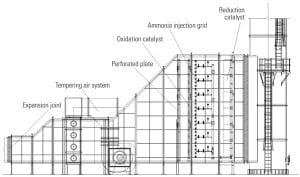

Automated Exhaust Temperature Control for Simple-Cycle Power Plants

A common concern for gas turbine power plants is treating exhaust gases to comply with laws restricting pollutants present in the gases that are emitted into the ambient atmosphere. The challenge for designers is to control the exhaust gas operating temperature within a range that maximizes performance of the oxidation and reduction catalysts.

-

Instrumentation & Controls

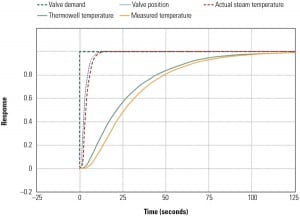

Thermocouple Response Time Study for Steam Temperature Control

One important factor in power plant control system performance is the response time of the process measurement used in the control system. The response time of boiler steam temperature sensors and thermowells is examined, as is those sensors’ and thermowells’ effect on desuperheater temperature response time and, therefore, steam temperature control performance.

-

Instrumentation & Controls

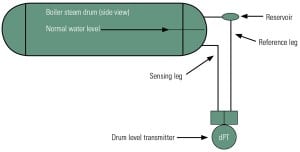

Concerns About Temperature-Equalizing Columns Used for Steam Drum Level Measurement

In the 1950s, temperature-equalizing columns were commonly used in steam drum differential pressure–based devices for measuring water level. However, these columns are problematic because a portion of the reference leg can flash to steam on a pressure decrease (load increase), and this will result in a temporary, false, high-level measurement, which adds to the swell effect. The columns can also result in measurement inaccuracies. It’s time to replace these antiquated instruments with a more modern reference leg.

-

Coal

Luminant’s Oak Grove Power Plant Earns POWER’s Highest Honor

Luminant used remnants of the ill-fated Twin Oaks and Forest Grove plants (which were mothballed more than 30 years ago) to build the new two-unit 1,600-MW Oak Grove Plant. Though outfitted with equipment from those old plants, Oak Grove also sports an array of modern air quality control equipment and is the nation’s first 100% lignite-fired plant to adopt selective catalytic reduction for NOx control and activated carbon sorbent injection technology to remove mercury. For melding two different steam generators into a single project, adopting a unique and efficient “push-pull” fuel delivery system, assembling a tightly integrated team that completed the project on time and within budget, and for completing what was started almost four decades ago, Oak Grove Power Plant is awarded POWER magazine’s 2010 Plant of the Year award.

-

Nuclear

The Value of a Knowledge-Based Culture Grows in Lean Times

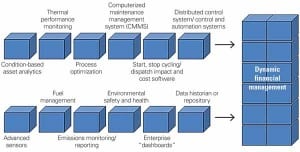

Given delays and cancellations of new generating capacity, pushing the existing power generation fleet is more important than ever. At ELECTRIC POWER 2009, multiple presentations explored the premise that an active knowledge management strategy — requiring a blend of digital and human elements unique to each power plant — will help you extract the most productivity from your assets.

-

O&M

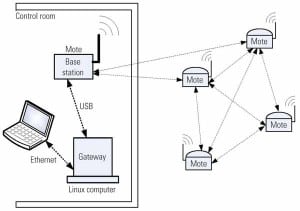

Low-Cost Wireless Sensors Can Improve Monitoring in Fossil-Fueled Power Plants

As equipment ages in fossil-fueled power plants, component wear leading to machinery failure increases as a result. Extending equipment life requires increased attention to maintenance, and one way to improve maintenance planning is to detect faults prior to failure so maintenance can be scheduled at the most cost-effective, opportune time. This type of strategy benefits from the use of additional sensors, and wireless ones can often be installed with the least time and cost.

-

O&M

How to Avoid Alarm Overload with Centralized Alarm Management

In 1999, the Engineering Equipment and Materials Users’ Association (EEMUA) released its general guide to the design, management, and procurement of alarm systems for industrial plants. The guidance document (EEMUA 191), however, is vague about applications to specific facilities, such as electric power plants. This article specifies EEMUA 191 standards and practices applicable to the electric power industry and spells out specific variations in alarming practices that are tailored for today’s power plants.