Instrumentation & Controls

-

Nuclear

THE BIG PICTURE: Nuclear I&C

Progress in electronics and information technology has created incentives to replace traditional analog instrumentation and control (I&C) systems in nuclear power plants with digital I&C systems, or systems based on computers and microprocessors. About 40% of the world’s operating reactors have been modernized to include at least some digital I&C systems, according to the International […]

-

Instrumentation & Controls

Drum Level Instrumentation Update

Accurate knowledge of the water level in any boiler drum application is an absolute necessity. While operating a boiler with low water level is one of the leading causes of boiler failure, operating with a high water level may produce less-than-optimal steam, as well as damage to the steam turbine by moisture carryover.

-

Instrumentation & Controls

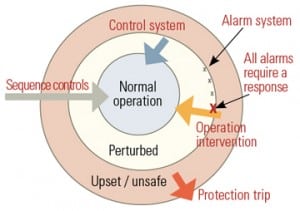

Plant Automation Advancements: The Australian Experience

Many recent utility greenfield and rehabilitation power projects have incorporated plant automation, with the goal of reducing the number of operators needed. The essential design principle is to specify control systems and field devices that will achieve the desired operational regime. Here’s how it’s done “Down Under.”

-

Instrumentation & Controls

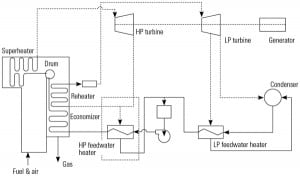

Coordinated Feedwater Heater Energy Control

The increased use of intermittent renewable energy sources and the shift to gas-fired combustion turbines places new burdens on the dispatch of many coal-fired units. Steam units must now operate at very low minimum load while maintaining the ability to ramp up and down quickly. High-pressure feedwater heater energy control can improve the system response of such coal-fired units.

-

Instrumentation & Controls

Thermocouple Response Time Study for Steam Temperature Control, Part II

Mismatched or poorly maintained temperature sensors and thermowells can cause an often-unrecognized error in steam temperature measurement. The problem is often recognized only when sluggish steam temperature response times are noticed. Recent tests suggest some simple ways to resolve the problem.

-

Environmental

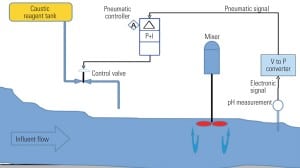

Sediment Pond Effluent pH Control

Many power plants have sediment retention ponds that require control of pH for the effluent. The following guidelines for fossil plant sediment pond pH control will help you design a robust system while staying within budget.

-

O&M

DHS: USB Drives Spread Malware in Control System Environment at Two Power Plants

A report by the U.S. Department of Homeland Security (DHS) Industrial Control Systems Cyber Emergence Response Team (ICS-CERT) reveals that infected USB drives spread common and sophisticated malware in the control systems at two power plants in separate incidents late last year.

-

Instrumentation & Controls

The Electric Grid: Civilization’s Achilles Heel?

Solar flares have proven destructive effects on transmission grids, but there are many other “black swan events” that threaten modern civilization. Experts disagree about which protective steps should be taken today.

-

O&M

As Cybersecurity Bill Dies, Newly Declassified Report Underscores Grid Vulnerabilities

Despite growing concern about cybersecurity both in and outside of Washington, the Senate’s cybersecurity bill died a second time on Nov. 13. The apparent inability of Congress to pass legislation designed to protect critical U.S. infrastructure could lead to President Barack Obama implementing some of the bill’s provisions via executive order. A day after the bill failed to gain 60 votes for passage, a recently declassified report was released that finds the U.S. power grid is vulnerable to attacks that could be more destructive than natural disasters such as Hurricane Sandy.

-

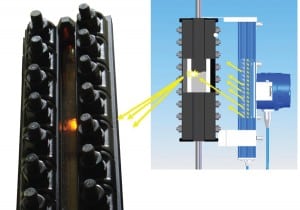

Nuclear

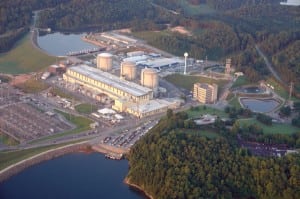

Top Plant: Oconee Nuclear Station, Seneca, South Carolina

With license extensions for its three units in hand, Duke Energy’s Oconee Nuclear Station began a digital controls upgrade program in 2006, and in January 2010, AREVA became the first supplier to receive Nuclear Regulatory Commission approval for a safety-related digital instrumentation and controls system.