Environmental

-

Legal & Regulatory

States should cede control of renewable power to regional markets

State policy makers are characteristically reluctant to recognize that they have advanced a policy as far as they can, and that they must cede some control to fully realize its ultimate benefits. Ceding control often runs counter to policy makers’ political instinct to serve their constituents. Doing so is even harder when a new […]

-

Coal

Speaking of Coal Power: Illinois Coal Poised for Comeback

Sylvester Stallone, as Rocky Balboa, staged another magical comeback earlier this year — in the ring and at the box office. Just when you think Rocky is down and out for good, the sixth release of the Rocky franchise just may be the best of the lot. "Down but not out" is also an apt […]

-

O&M

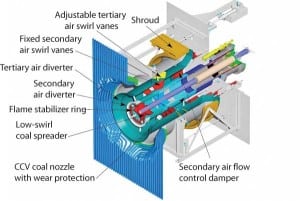

Pollution Control: Low-NOx Combustion Retrofit Options

Reducing NOx emissions from large utility coal-fired boilers has been a primary focus of the U.S. power generation industry since passage of the 1970 Clean Air Act and subsequent legislation. By the early 1990s, nearly all such boilers had installed some form of low-NOx burner (LNB) technology and/or overfire air (OFA) — the least expensive […]

-

O&M

Focus on O&M (April 2007)

Control pollution and slagging on a shoestring / Keeping HRSGs young, cool, and clean / Natural air conditioning

-

Coal

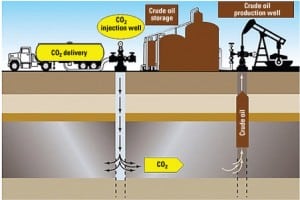

Exploring the many carbon capture options

Carbon capture and sequestration have many technical hurdles to leap in coming years. The capture and reuse of CO2 to enhance oil recovery preceded the current clamor over climate change, and that experience is often used as an example that the process is a viable way to handle this greenhouse gas. This article explores options for the first part of the process: CO2 separation and capture.

-

O&M

SO3’s impacts on plant O&M: Part III

Part I of this three-part series (POWER, October 2006) explored the negative impacts of sulfur trioxide (SO3) on the operations and maintenance of back-end plant equipment. Part II (February 2007) listed and quantified the likely and potential benefits of limiting the concentration of SO3 in flue gas to 3 ppm at the entrance to the air heater. This final part describes the characteristics of an optimal SO3 removal technology and details the operating experience of a patented process that has worked successfully at a half-dozen plants for up to three years.

-

O&M

Speaking of Coal Power: Coal in a Carbon-Constrained World

Carbon capture and sequestration (CCS) have elbowed their way into the nation’s lexicon with the rise in concern over climate change. But few of the journalists who are hyping global warming have taken the trouble to learn the ins and outs of producing affordable electricity from coal. Citizens of the industrialized world now wring their […]

-

Coal

The Coal Patrol: Glaciers and New Coal Plants

The big buzz still echoing through world of coal-fired generation is the move by two big-bucks private equity investors to take TXU Corp. off the public market, including scuttling announced plans for eight new pulverized coal – fired plants. That leaves alive plans for three new units at TXU’s existing Sandow and Oak Grove sites. […]

-

Environmental

Birds in the hand for CO2

The January call for a national policy on greenhouse gas (GHG) emissions by a coalition that includes some of America’s largest companies and electric utilities—GE, Alcoa, Dupont, Duke, FPL, and PG&E—makes clear that carbon management is now as much of a raison d’être for CEOs as it has been for environmentalists. The momentum to reduce […]

-

Gas

Global Monitor (February 2007)

China to buy four AP1000 reactors / Midwest Gen, Blagojevich reach pollution deal / Behold, the carpet gasifier / AREVA casks green-lighted by NRC / Brookfield Power upgrades Oswego Falls / Korea fires up 50-MW landfill gas project / Alstom lands big Russian deal / POWER digest / Correction