Coal

-

Coal

EPA to Clamp Down on Coal Plant Wastewater

The Environmental Protection Agency announced it plans to “revise” existing, decades-old guidelines for water discharges of toxic metals from fossil fuel-fired power plants, saying a recently concluded EPA study focused mostly on wastewater discharges from coal-fired power plants uncovered elevated levels of toxic pollutants.

-

Coal

EPA Finalizes Greenhouse Gas Reporting Rules

In a major climate change rulemaking, the Environmental Protection Agency has issued final regulations that will require most large emitters of greenhouse gases in the U.S. to report their emissions beginning in 2010.

-

O&M

Texas Wind Boom Cutting into Fossil Generator Profits

Can wind turbines actually reduce the amount of fossil fuels consumed? A Wall Street Journal analysis concludes that ERCOT utilities will begin to feel the squeeze in their profits this year and to expect the amount of fossil fuels used to generate electricity to be reduced.

-

O&M

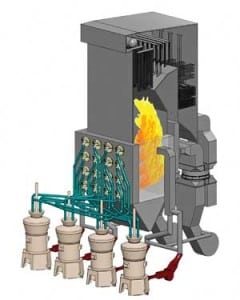

Zonal Combustion-Tuning Systems Improve Coal-Fired Boiler Performance

Coal-fired power plants that fire low-cost coals or that are equipped with combustion modifications for NOx controls are challenged with maintaining good combustion conditions while maximizing generation and minimizing emissions. In many cases, significant unit derates, availability losses, and an increase in unburned carbon levels can be attributed to poor combustion conditions that occur as a result of poorly controlled local air/fuel distribution within the boiler furnace. Fortunately, a new generation of combustion optimization technologies is available that uses burner air and fuel controls and spatially distributed combustion monitors to detect and correct local furnace air/fuel distribution imbalances.

-

O&M

Condenser Tube Life-Cycle Economics

The decision to retube a heat exchanger or condenser begins with understanding why tubes are failing. Only when the “why” is understood can the economic replacement tube material be selected. We explore the most common tube material failure mechanisms and then illustrate how to perform a proper life-cycle analysis for that new set of condenser tubes your plant so desperately needs. In sum, there are many reasons to consider getting the copper out of your condenser.

-

Coal

Court Revives CO2 “Nuisance” Suit Against Utilities

In another major legal victory for states pressing for controls on industry emissions of carbon dioxide, a federal appeals court has reversed a lower court decision and ruled that eight states and the city of New York City could bring “nuisance” suits against five coal-burning utilities to curb greenhouse gas discharges that the states claim are causing damage to their natural resources.

-

O&M

Update: Benchmarking Boiler Tube Failures

Boiler tube failures continue to be the leading cause of downtime for steam power plants. Is your boiler tube failure reduction program showing improvement when compared to programs at peer plants? The EUCG’s recent update of its boiler tube failure study can help you answer that question. The full study is available only to members, but this POWER exclusive presents many of the key results, which could help you improve the operation of your plant.

-

Coal

Coal-Fired Generators Worried About Getting Burned

The expected renaissance for U.S. coal-fired generation has been more evolutionary than revolutionary: Less than half of the announced plants will likely progress to construction. However, the percentages for coal-fired plants aren’t significantly different from those for combined-cycle plants a decade ago, when dozens were ultimately canceled, leaving developers with warehouses full of unused gas turbines. The difference this time: The threat of carbon control legislation has moved many projects to the “wait and see” category.

-

O&M

Measuring Coal Pipe Flow

Once pulverized coal flows have been measured, they can be balanced and optimized. Until then, tuning is simply guesswork. The right way to balance furnace fuel flows is to establish solid baseline performance by proper measurement of fuel flow, fineness, and velocity. Only then can all the coal pipes be accurately balanced and followed by a tune-up of the boiler controls.