-

Instrumentation & Controls

Wireless Technology Unlocks Possibilities

Modern wireless systems improve productivity, monitoring activities, and safety at power plants by enabling the right people to be at the right place at the right time. Wireless technology can put hard-to-access process and asset information at your fingertips, wherever you are, to enable more accurate and timely decisions.

-

Solar

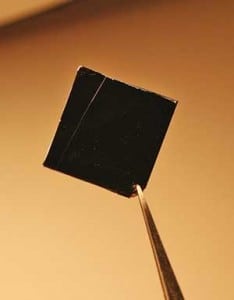

New Technologies Could Improve Solar Cell Efficiencies

Declining oil prices, supply issues, and dwindling financing may have battered solar energy in recent months, but the industry seems to have sparred well in the research arena. An assortment of institutions separately announced breakthroughs in their quests to boost the efficiency of solar cells. The technological advancements ranged in approach, from the development of an antireflective coating to the formulation of more efficient solar cell materials, but all point to promising possibilities for the industry.

-

Coal

New Laser Technology Helps Reduce Coal-Slagging Headaches

Laser-induced breakdown spectroscopy is starting to light the way for power plant operators who want to reduce coal ash deposition in their boilers.

-

Business

An Energy-Generating Door

An energy-generating revolving door installed at Driebergen-Zeist railway station in the Netherlands is the latest experiment in eco-building. Dutch company Royal Boon Edam Group Holdings designed the manual door to match the newly refurbished station’s sustainable technology theme, while keeping in mind that the station — converted into a multifunctional area featuring restaurants and a tourist information and visitor center — holds 8,500 commuters at capacity.

-

Business

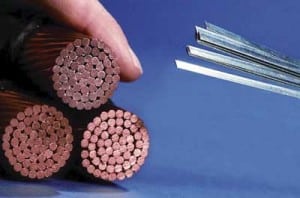

HTS Cables Speed up the Electric Superhighway

High-temperature superconducting cables deliver up to 10 times as much power as conventional electric power transmission cables. They are poised to help to reduce grid congestion as well as installation and operating costs.

-

Coal

Sri Lanka Commissions Major Thermal Power Plant

The Sri Lankan government in December commissioned the first phase of the 300-MW Kerawalapitiya Thermal Power Plant, the nation’s biggest combined-cycle power plant project. The $300 million plant in the western part of the country commenced operations by generating 200 MW (Figure 7). In its second phase, it will expand to 300 MW. Per government estimates, power produced by the plant is priced at about 20 rupees or $0.18/kWh.

-

Business

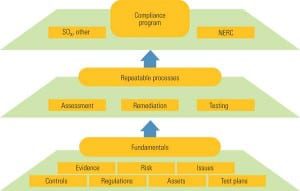

NERC Drives Development of Sustainable Compliance Programs

Compliance with reliability standards has moved beyond the "check the box" phase to one of regulations with real deliverables and fines for noncompliance. Utilities that aren’t vigorously evaluating and refining their compliance procedures today may find NERC’s 2009 audit cycle much more challenging.

-

O&M

FERC Focuses on Internal Compliance Programs

By now, most electric industry participants are aware of the mandatory reliability standards required by the Energy Policy Act of 2005 and managed by the North American Electric Reliability Corp. (NERC). Bulk-power system users, owners, and operators (known as NERC registered entities) are responsible for complying with the set of standards that are applicable to their operations in their specific region. Compliance is monitored by the NERC regions (Texas Regional Entity, Western Electric Coordinating Council, Reliability First Corp., Midwest Reliability Organization, SERC Reliability Corp., Florida Reliability Coordinating Council, Northeast Power Coordinating Council, and Southwest Power Pool) through spot checks, self-certifications, audits, and investigations.

-

News

Upward Mobility

The Max Climber 2000P-IPM rack and pinion personnel and material elevator by Beta Max Inc. uses little space while providing a safe and efficient means of access for workers performing maintenance work at high levels. The Max Climber 2000P-IPM easily attaches to scaffolding or a building exterior and is designed with a base system footprint […]

-

O&M

Preventing Boiler Code Violations Creates a Safer Work Environment

Nearly 10% of boilers and pressure vessels inspected in the second quarter of 2008 were slapped with violations, which means that the violations put workers and equipment in danger, according to a quarterly report released by the National Board of Boiler and Pressure Vessel Inspectors.

Search