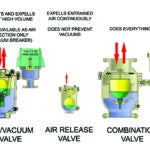

The Air/Vacuum Valve automatically exhausts large volumes of air from the system while it is being filled with the slurry. When the contamination is being emptied, air displaces the fluid and re-enters the pipeline to equalize pressure. It prevents discharge of the medium to keep your work environment clean and safe.

When the system is filled and operating, the fluid lifts the ball until it closes the orifice. The orifice will remain closed until the system is emptied. Air may enter the valve and displace the fluid while the system is operating, but the internal pressure will keep the valve tightly shut. The valve will not re-open until the system pressure drops to near atmospheric pressure and the ball is no longer buoyant.

Features

•No blocking or leakage.

•No sticking due to rotating ball.

•Secondary seal for positive seal.

•Fabricated and can be repaired in line.

•Self cleaning ball action.

Sizes

•2” – 8”

Pressures

•240, 365, 600,1500 psig

•Specials on request

Specifications

•Valve housing is fabricated from carbon steel or stainless steel (304 or 316).

•The orifice is the same size as the valve inlet and outlet.

•Valve housing can be epoxy coated.

•Valve housing can be natural rubber lined. A Range of elastomer grades are available for corrosive duties.

•Guided urethane floating ball, solid urethane or hollow stainless steel for high pressure.

•The seat is made of rubber low pressure sealing and for sealing in slurry.

•Flanges are typically made of carbon steel or stainless steel and drilled to customer requirements.

•Working pressure standards are 150 up to 1500 psig for air release valves, and up to 240 psig for combination valves for use on slurries.

•Operating temperatures to 176°F. Higher conditions are possible

Contact:

Lane Maloney, Marketing

Larox Flowsys, Inc.

410-636-2250

lane.maloney@larox.us

www.larox.us