When an electric utility with a power plant in the southwestern U.S. prepared for a planned, major outage on its two Siemens 501D turbines, the plant’s manager requested a repair quote for two directional control valves and two gas valves attached to each turbine.

“We had a problem with one of our controllers that lead to an outage that we fixed, but we also received ‘Condition Yellow’ and ‘Condition Orange’ grid alerts from the RTO,” said the plant’s reliability manger. “With the combination of an unplanned outage and the alerts, we wanted to be sure we had capacity; we didn’t want any of our generation resources limited in any way.”

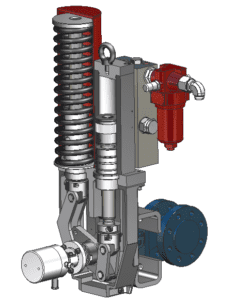

In responding to the request, Controlled Fluids Inc. (CFI), a distributor of motion control technology designed by Moog Inc., informed the plant managers that the Moog valves were an obsolete series and discussed replacing these as well as the Moog 025 and 026 Series actuators controlling them. The replacements would be newer Moog 094 Series hydraulic actuators.

“They were coming up on their cycle for outages,” said Nick Albarado, an integrator for Beaumont, Texas-based Controlled Fluids. “The plant managers were inquiring about servicing the turbine’s actuators, and we were able to bridge a gap between Moog and Siemens.”

According to Albarado, if a power plant or turbine operator has the obsolete Moog valves and actuators mentioned above, the plant managers need to replace them. This replacement involves planning to ensure the new equipment functions exactly like the old versions. Moog also requires time to accommodate any difference in fittings between the old and new valve sets.

Work Begins

Once the plant agreed to work with CFI, the Texas company performed a field survey of model numbers, physical limitations, and orientations. Next, CFI quoted the added value for its field service to remove and install new gas valves and run new hydraulic and electrical connections as well as actuators. By way of background, the inlet guide vane actuators and fuel gas control valves on the Siemens turbines regulate the ratio of air and fuel in varying loads for efficiency and minimal emissions. The purchase order for the work totaled $850,000, not including CFI’s field services.

“The turbine experts at CFI and Moog convinced us that a third-party repair might be less, but the Moog equipment would last up to 30 years, and the new valves and actuators are made to the OEM specifications,” recalls the plant’s reliability engineer.

According to Albarado, when you’re dealing with power generation, you need a guaranteed commitment that your actuators will be removed on a certain date, refurbished, returned, and replaced within the planned outage window. The plant manager also needs to know if the actuators will remain effective until their next planned repair date.

“The cycle at most plants is a major, planned outage every six years,” added Albarado, “and a minor one every three years where you’re not necessarily changing out the turbine’s actuators.”

Installing the new Moog actuators and valves took place late last year, so the components will next require service in 2030. Initially, the plant managers contracted CFI Field Service Manager Brad Little to install the first of the actuators and valves, while the plant’s personnel observed. However, the plant manager ultimately decided to have Little observe as the plant’s employees installed actuators and valves on both turbines.

“Moog supplied the valves and actuators along with the new hydraulic and electrical connections, CFI provided oversight,” said the reliability engineer for the plant. “We did the mechanical install, and CFI had an equipment trailer on site to make hoses based on the measurements they took, which helped; there’s a complex bit of hoses, four valves each with two hoses.”

The equipment and services CFI and Moog provided the plant included the Moog 094 Series rotary hydraulic actuators for Siemens turbines, supervision of the removal and installation of two sets of gas valves, and HPU maintenance.

The Moog 094 Series offers several improvements over the obsolete Series 025 and 026. For example, if power is lost, the Moog 094 Series actuator’s failsafe mechanism reverts to the closed position, unlike the obsolete designs. The 094 Series actuator holds the valve closed with a mechanical spring; normally, the actuator works against the spring to open the valve and hold a desired position. Hydraulic force acts in one direction, with the spring generating the opposing force. In the failsafe configuration, a three-way servo valve is applied with a single acting hydraulic cylinder.

When using the 094 Series actuator to replace the Moog 025 and 026 models, the failsafe feature is bypassed by removing the trip solenoid cartridge valve and replacing it with a simple cavity plug. This allows the actuator to function as designed in the fuel metering application. The 094 Series also incorporates: current; available control devices for the rotary viable differential transformer; and a filter differential pressure alarm, which runs on 24 volts direct current.

“The differential pressure gives you a good indication of when you’ve gone into bypass and whatever is downstream of that filtration,” said Albarado. “The alarm provides the turbine owner with a window into the oil health. If, for example, filters are failing at an accelerated rate, the turbine operator knows there is an issue. It could be a contamination issue or ingress somewhere along the line.”

The standard Moog 094 Series actuator operates on +/-30 milliamps control signal. For retrofit applications, Moog and its distributor will use a new servo valve that matches the original+/-40 mA signal. The Moog 094 Series actuators have the same hazardous location certifications as the original Moog 026 and 026 actuators.

If the plant hadn’t tapped CFI and Moog for this work, they might have picked an unauthorized repair house to replace the actuators and valves. But turning to an URH is risky. “Refurbished” actuators from any third-party pose a high probability of failure, say experts, triggering a forced outage for a power plant turbine.

—Bill Perry is managing partner with MARCH 24 Media.