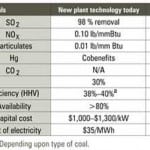

Four research projects that could further carbon capture technologies—helping them achieve at least 90% carbon dioxide removal with no more than a 35% increase in power costs—were on Monday selected for further development by the Department of Energy’s Office of Fossil Energy.

Projects focus on slipstream-scale development (0.5 MWe to 5 MWe) and testing of advanced solvent-based post-combustion carbon capture technologies.

The projects are being managed by the National Energy Technology Laboratory (NETL) and have been valued at about $67 million (including $15 million in non-federal cost sharing) over four years. NETL said advanced CO2 power plant capture systems are a key element in carbon capture, utilization, and storage (CCUS) technologies.

It noted, however, that existing carbon capture systems currently require large amounts of energy for their operation, resulting in decreased efficiency and reduced net power output when compared to plants without CCUS technology. “These penalties can add as much as 80 percent to the cost of electricity for a new pulverized coal plant.”

The projects include:

- Southern Co.’s development and demonstration of waste heat integration with solvent process for more efficient carbon dioxide removal from coal-fired flue gas. Backed by the DOE, the Atlanta-based company will develop viable heat integration methods for the capture of CO2 produced from pulverized coal combustion using a waste heat recovery technology (High Efficiency System). This technology will be integrated into an existing 25-MW pilot amine-based CO2 capture process (KM-CDR) at Southern Co.’s Plant Barry. Modeling by Mitsubishi Heavy Industries America indicates that a fully heat integrated High Efficiency System will improve by 26% the thermal energy performance of the integrated KM-CDR and plant operation. The DOE will contribute $15 million to the project.

- Linde LLC’s slipstream pilot-scale demonstration of a novel amine-based post-combustion process technology for carbon capture from coal-fired plant flue gas. The proposed project will use a post-combustion capture technology incorporating BASF’s amine-based process at a 1 MWe equivalent slipstream pilot plant at the National Carbon Capture Center. “This technology offers significant benefits as it aims to reduce the regeneration energy requirements using novel solvents that are stable under the coal-fired power plant feed gas conditions,” NETL said. The DOE will contribute $15 million to the project.

- Colorado-based Neumann Systems Group’s carbon absorber retrofit equipment (CARE). Located at the Colorado Springs Drake #7 power plant, the group will design, construct, and test a patented NeuStream absorber. The absorber will use nozzle technology proven during a recently completed 20-MW NeuStream-S flue gas desulfurization pilot project, and an advanced solvent that efficiently captures CO2. This absorber technology is applicable to a variety of solvents and can be added to existing pulverized coal power plants with reduced cost and footprint. “Because of the modularity of the NeuStream technology, it can be rapidly scaled to larger size systems and retrofitted into existing plants with little risk,” NETL said. The DOE plans to contribute $7.2 million to the project.

- University of Kentucky Research Foundation’s application of a heat-integrated post-combustion carbon capture system with Hitachi advanced solvent into an existing coal-fired power plant. Researchers plan to use an innovative heat integration method that uses waste heat from a Hitachi H3-1 advanced solvent carbon capture system while improving steam turbine efficiency. The proposed process also implements a process concept (working with the heat integration method) that increases solvent capacity and capture rate in the CO2 scrubber. The novel concepts and advanced solvent used in this study are expected to significantly improve the overall plant efficiency when integrated with CO2 capture systems, and can be applied to existing coal-fired power plants. The DOE will contribute $14.5 million to the project.

Sources: POWERnews, NETL