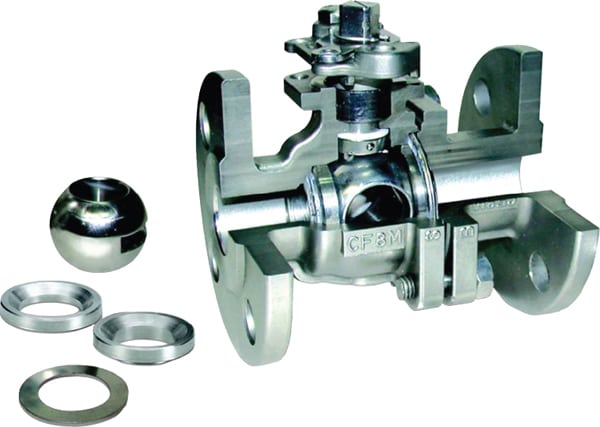

The new M-series metal seat ball valves from A-T Controls are engineered with specially coated matched balls and seats to stand up to high temperatures, high pressures, and abrasive materials encountered in the power generation industry. Valves in the M-series have a temperature range of –20F to 661F and a pressure rating up to ANSI class 600. M-series ball and seat materials include stainless steel, satellite-welded, and hard chrome-plated steel, allowing the valves to perform well in applications involving abrasive fluids and steam. Two optional coatings are also available: a tungsten carbide coating for heavy slurry environments and a chrome carbide coating for higher-temperature applications. An oversized stem prevents deformation at higher pressures and temperatures. Larger ball design provides a tight seal, preventing leakage, and an Inconel seat spring maintains positive contact between the ball and seat during operation. Valves are available with four connection options: flanged, threaded, socket weld, and butt weld. Body material options include WCB, CF8, and CF8M. (http://www.a-tcontrols.com)