Japanese utility giant JERA and automotive technology firm DENSO have begun Japan’s first demonstration of hydrogen production using solid oxide electrolysis cell (SOEC) systems at JERA’s Shin-Nagoya Thermal Power Station in Nagoya, Aichi Prefecture, a 3,058 MW combined-cycle LNG facility.

The demonstration tests 200-kW SOEC water electrolysis systems developed by DENSO with the key aim of achieving “hydrogen production with the world’s highest-level electrolysis efficiency by applying DENSO’s heat-management technology to minimize the heat discharged by the SOECs”.

The project represents Japan’s first attempt to integrate hydrogen production within thermal power infrastructure as utilities seek new revenue streams while advancing decarbonization goals.

DENSO’s SOEC system at Shin-Nagoya operates at about 700C, using advanced ceramic membranes as the electrolyte to split steam into hydrogen and oxygen. The approach leverages high-temperature steam electrolysis (HTSE) to enable substantially higher electrical efficiency than conventional low-temperature techniques.

The description of SOEC operation draws on DENSO’s SOEC technology disclosures, including its 2024 joint-development announcement with JERA and earlier demonstrations. In August 2024, DENSO and JERA explained that SOECs function by feeding steam into a ceramic electrolyte—yttria-stabilized zirconia—where water vapor at the cathode is reduced to hydrogen while oxygen ions migrate through the membrane to the anode, releasing oxygen.

By operating at high temperatures (700C), SOECs leverage thermal energy to lower the cell voltage required for electrolysis, boosting their electrical efficiency to about 80%. That compares to 65–70% for alkaline and PEM electrolyzers operating at 60C and 80C, respectively.

A key innovation involves integrating thermal management techniques derived from DENSO’s automotive components expertise—sophisticated temperature control systems that optimize internal heat flows to maintain stable high-temperature operation and prevent material degradation. The design also employs ejector technology, rooted in automotive fuel systems, to recycle unreacted steam within the electrolyzer, further enhancing overall thermal and electrical efficiency, the company says.

DENSO’s 2023 demonstration at its Hirose manufacturing plant showcased similar heat-management and steam-ejector recycling technologies to capture unreacted steam and reroute low-grade waste heat back into the SOEC stack.

The demonstration at Shin-Nagoya will explicitly seek to minimize the heat and waste energy discharged by the SOEC system. “Going forward, based on the results of the demonstration testing, we aim to scale up the electrolysis power from 200 kW to several thousand kW as we accelerate efforts to drive the practical application of SOEC next-generation fuel production systems,” JERA said.

JERA, Japan’s largest power generator supplying approximately 30% of domestic electricity, has committed to achieving net-zero CO2 emissions from domestic and international operations by 2050. The utility operates through fuel upstream development to power generation and wholesale operations. DENSO, an automotive supplier headquartered in Kariya, Japan, has targeted carbon neutrality by 2035 through manufacturing initiatives, mobility products, and hydrogen energy utilization.

Shin-Nagoya, located near Shiomi Pier, Minato-ku, is built next to a 17-kilometer gas pipeline from the Chita LNG Terminal. The plant comprises two combined-cycle blocks: Group 7, operational since late 1998, pairs six 243 MW, 1,300C gas turbines with triple-pressure heat-recovery steam generators; and Group 8, which came online in 2008, and integrates four 400-MW, 1,500C turbines. An on-site 330 kV GIS switching station connects directly to Chubu Electric’s grid, while an adjacent desalination unit provides feedwater for both steam cycles and the new SOEC module. A dedicated hydrogen system at the plant already produces generator-cooling hydrogen in situ.

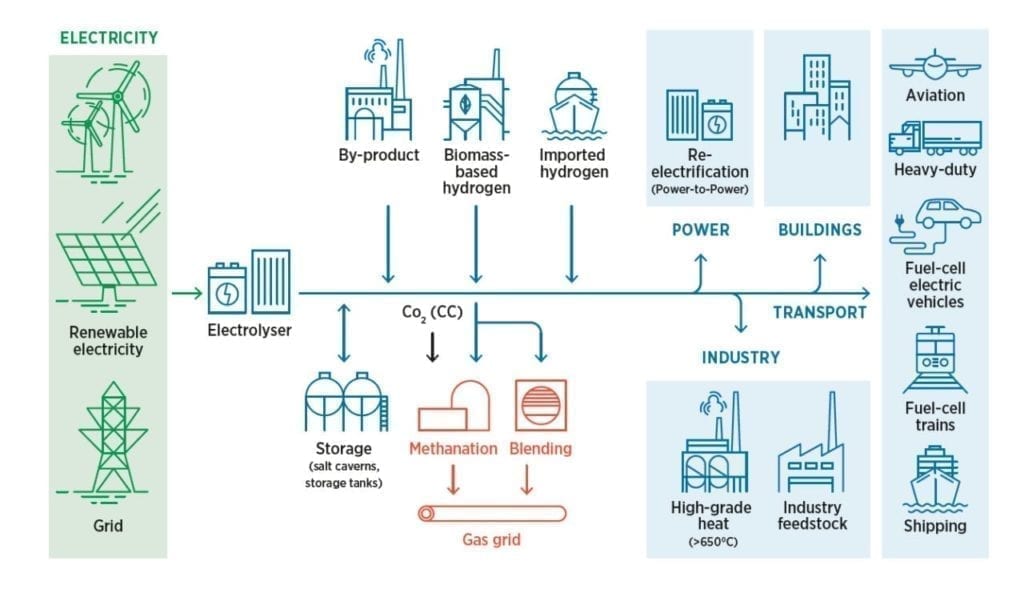

Still, JERA’s hydrogen ambitions extend well beyond the SOEC pilot at Shin-Nagoya. Under its JERA Zero CO₂ Emissions 2050 roadmap, the company is building an end-to-end hydrogen and ammonia supply chain while converting existing thermal units to zero-emissions fuels. For example, JERA plans to co-fire up to 20% ammonia at its 4.1-GW Hekinan coal station by the early 2030s, ramping up from small-scale trials completed in June 2021 to full-scale demonstration in Unit 4.

In parallel, JERA secured government approval in August 2021 to pilot 30% hydrogen co-firing at a large-scale liquefied natural gas plant, seeking to replace one-third of turbine fuel by 2025 and learning key lessons on flame stability and NOₓ control.

And beyond Japan, JERA is collaborating with ExxonMobil to explore equity participation in a 900,000 t/y low-carbon hydrogen and 1 million t/y ammonia complex on the U.S. Gulf Coast. JERA’s off-take rights are for up to 500,000 t/y of clean ammonia for domestic supply.

“Through this joint demonstration testing, both companies will work for the early establishment of a global supply chain for green hydrogen and ammonia and contribute to finding solutions for global decarbonization and energy issues,” the companies said on Thursday.

—Sonal Patel is a POWER senior editor (@sonalcpatel, @POWERmagazine).