MD&A

-

Partner Content

Casing/ Shell Weld Repairs & Re-Rounding

Sponsored by:

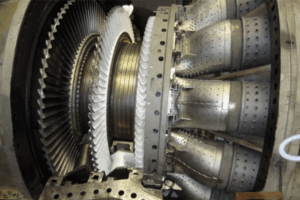

For many years, the OEM fix for major cracking or shell distortion was replacement of the defective shell, also referred to as casing by some OEMs, with new. Mechanical Dynamics and Analysis has provided an alternative to shell replacements which includes fixing the existing shell to extend its life. MD&A recently welded and repaired the HPIP […]

Tagged in: -

Partner Content

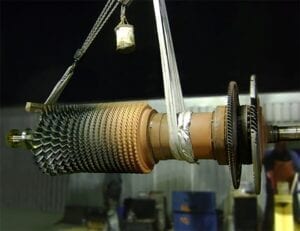

Field Rewind with a Rotor Slot Dovetail Repair

Sponsored by:

Mechanical Dynamics & Analysis (MD&A) recently completed generator field rewind with a rotor slot dovetail repair on a customer’s GE® 650,000 KVA generator field. The work scope was performed at the customer’s direction with regards to applicable Technical Information Letters. Incoming visual and mechanical inspections were first completed, as well as a runout inspection in the lathe which […]

Tagged in: -

Partner Content

Steam Turbine Rotor Straightening in Abu Dhabi

Steam turbine work on the international stage can have its challenges, but also its successes. Mechanical Dynamics & Analysis (MD&A) was contracted to inspect, analyze, and then straighten a Toshiba® steam turbine rotor in Abu Dhabi, United Arab Emirates. MD&A launched its team into action for a full analysis of the issues followed by a resolution of […]

Tagged in: -

Webinar

Steam Path Audit

Sponsored by:

MD&A’s Steam Path Audit webinar describes the technical process of conducting a visual inspection of a steam turbine’s steam path for the purpose of identifying and quantifying deficiencies in thermal efficiency. The results of the inspection are used to determine the root cause of efficiency degradation and to guide maintenance during an outage such that […]

Tagged in: -

Gas

Life Time Extension of Gas Turbines Components

Sponsored by:

In this webinar we will cover the typical limiting factors of gas turbine components and how they can be repaired. We will cover the steps used in implementing a life time extension and will show some case studies. Some examples of how new parts are redesigned with features that make them more robust will also be covered.

This webinar will be beneficial to the engineers and power plant personnel involved with the refurbishment and replacement of the gas turbine hot gas path components.

Tagged in: -

Partner Content

How to Extend the Lifetime of Gas Turbine Parts

Sponsored by:

Elevated temperatures take a big toll on gas turbine components risking cracks, corrosion, wall thickness, and material condition. Repair enhancements can extend a part’s life by slowing its degradation and pushing out its usable service life. Operators can see significant savings by opting for lower-cost repaired spares instead of new parts as demonstrated in the following case studies.

Tagged in: -

Partner Content

Behind the Scenes: Turbine and Generator Inspection and Repair in 19 Days

Sponsored by:

The countdown was set for T-19 days to complete a 7FA gas turbine hot gas path inspection together with a 7FH2 generator inspection and repairs providing all services, labor, and parts. While the average time for such project can be much higher, the Mechanical Dynamics & Analysis (MD&A) team of experts was able to perform a carefully

Tagged in: -

Gas

Test Your Knowledge: Competitive Maintenance Strategies

Competitive maintenance uses an analytical process and condition-monitoring tools to select the optimum maintenance strategy for each plant system. For example, the optimum strategy for the plant’s steam turbine will be different than that for its gas turbine, and vastly different than that of its feedwater pumps. How well do you know your maintenance strategies? […]

Tagged in: -

Partner Content

MD&A IBECS® – The Integrated Solution to Power Plant Control and Monitoring

Sponsored by:

Power plant control and monitoring can be complex given the need to integrate many different platforms. Adding to the complexity is the fact that HMI’s (Human-Machine Interface) supplied by the OEM often only interface with the OEMs controller and not with ancillary systems. Lastly, ongoing support and updates from the common operating system may be […]

Tagged in: -

Partner Content

Gas Turbine Major and Generator Test & Balance

Sponsored by:

Mechanical Dynamics and Analysis (MD&A) was contracted after a forced outage to perform a major overhaul on a cogeneration unit’s MS5001PA gas turbine, and to remove, test and inspect the generator field. Because the unit dispatches as baseload and the turbine is a critical asset, MD&A was asked to complete the repair work as quickly […]

Tagged in: