Features

-

Nuclear

ISA/EPRI conference offers a smorgasbord of control cuisines

This year’s main course, as usual, was instrumentation and controls. Side dishes of digital nuclear plant controls, plant controller and IT security, corrosion monitoring, and model predictive control added their own distinctive flavors. There was something for every taste, from the theoretical to the practical.

-

O&M

Mergers present challenges—and opportunities—for plant managers

The sale or merger of any company takes its toll on employees. Though it’s merely a hassle adapting to a different T&E form, the sudden uncertainty about health-care coverage and pension can be truly stressful. For plant managers, the impact is even greater—adapting to a new budgeting process and reporting requirements, not to mention answering hundreds of subordinates’ questions about the future, even before the deal closes. However, plant managers may actually end up better off as a result of a merger or acquisition.

-

O&M

Profiling your plant engineering staff

The latest benchmarking study by the EUCG examines the engineering and technical staffing of 62 plants, 92% of which burn coal. If you benchmark your units, plants, or fleet, the results may raise some eyebrows. But they also may help justify your plea for more intellectual capital during the upcoming budgeting cycle. Though the detailed results of the study are proprietary to EUCG member companies that participated in it, POWER was given access to the complete findings. If you want details at the plant/unit level, you’ll have to join the EUCG and participate in the study, which is ongoing.

-

Business

Gencos embrace benchmarking as strategic tool

Today’s utility business models re-emphasize utilities’ traditional mission—producing and delivering reliable, affordable power. Tracking how well that mission is executed is the raison d’être of modern plant performance benchmarking.

-

Coal

Coal: The cornerstone of America’s energy future

In April 2005, U.S. Secretary of Energy Samuel W. Bodman asked the National Coal Council to develop a “report identifying the challenges and opportunities of more fully exploring our domestic coal resources to meet the nation’s future energy needs.” The council has responded with eight specific recommendations for developing and implementing advanced coal processing and combustion technologies to satisfy our unquenchable thirst for energy.

-

Coal

Globalization: The new millennium’s "invisible hand"

Participants in the CEO Roundtable at Electric Power 2006 raised a plethora of issues affecting decisions on future electric power generation. Representing a cross section of power producers, the industry leaders made clear that, although globalization has lost its luster in the power generation sector, its impact on the domestic industry remains profound. Ten years […]

-

Coal

Safety still Job No. 1 for PRB users

If coal is to be “America’s energy future” (see p. 42), the work of the Powder River Basin Coal Users’ Group (PRBCUG) will have a lot to do with making it so. Since 1999, the PRBCUG (see sidebar) has fostered the safe, efficient, and cost-effective use of the fuel as it watched its membership swell […]

-

Synfuel

Combined Cycle Users’ Group completes another successful year

The third annual meeting of the Combined Cycle Users’ Group (CCUG) was held May 2–4 in Atlanta at Electric Power 2006, in cooperation with the ASME Power Division Combined Cycles Committee and other industry groups. The CCUG’s leadership (Figure 1) drives the group to address issues involving the major components of a combined-cycle plant and […]

-

O&M

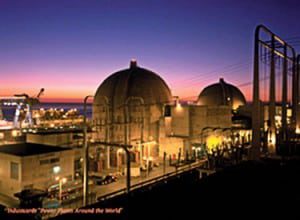

Improving the reliability of turbine lube oil supply

Five years ago, San Onofre Nuclear Generating Station’s Unit 3 turbine experienced substantial damage after the supply of oil to its bearings failed. Because the turbine coasted down without oil after it tripped, its bearings, journals, and steam path needed extensive repairs. A follow-up investigation revealed lube oil system vulnerabilities that were subsequently corrected. The lessons learned might also improve your turbine-generators’ lube oil reliability, saving you many millions in lost revenues.

-

Coal

How accurate primary airflow measurements improve plant performance

Primary airflow has a major impact on the efficiency, capacity, and cleanliness of pulverized coal–fired generation. Inaccurate measurements that underestimate primary airflow levels can lead to negative operational outcomes that include increased boiler gas temperatures, flyash loss-on-ignition, excessive NOx emissions, and higher-than-necessary fan power consumption. We remind you how to avoid those headaches.