Features

-

Nuclear

Flies in the nuclear power ointment: Supply chain complexity, shortage of skilled labor

Perhaps the most interesting aspect of the nuclear track at the ELECTRIC POWER 2007 Conference & Exhibition (EP07) in Chicago last month was the attendance. For the most part, its sessions were jammed, leading session chairmen to mention how different this was from prior years. Clearly, nuclear has buzz. The environment looks promising: The regulators […]

-

Coal

Climate change concerns drive projects to curb CO2

In a carbon-constrained world, CO2 capture and storage (CCS), although considered the most radical of the carbon abatement technologies (CATs), seems to be favored over combustion and steam cycle improvements alone. However, CCS is the least commercially developed of the CAT options; at present, there are only field prototypes for its various forms. Nonetheless, most […]

-

Smart Grid

Smart grid still just a "vision thing"

T&D systems with embedded intelligence have a great future, and they always will. Too many powerful forces—politics, money, and power—remain to be reconciled before consumers and utilities can work together, seamlessly, to reduce electricity demand and eliminate delivery system bottlenecks.

-

News

Retrospective

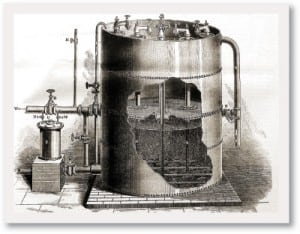

June 1886 POWER reported on the art and science of water treatment and its effect on boiler performance in the cover story this month. "Dr. J.G. Rogers, an authority on steam generation, is quoted as stating that one-sixteenth of an inch of scale in a boiler will require the extra consumption of 15% more fuel; […]

-

Waste to Energy

Experts ponder future of biomass industry

This month we officially commemorate the 125th anniversary of the magazine that has been essential reading for owners and operators of power generating plants. As you read this brief history, you’ll see that—although we’re looking back at an illustrious past—the secret of POWER’s success has been its commitment to the future. As we look forward to the next milestone anniversary, we anticipate covering the latest developments in a new generation of power technologies. As always, our mission is to provide the best information and advice in the service of safely and efficiently powering the global energy industry.

-

Nuclear

Transfer ABWR construction techniques to U.S. shores

Advanced boiling water reactor (ABWR) construction practices honed in Japan aren’t just impressive, they’re also eminently suitable for the fleet of new units planned for the U.S. Conceptually, these techniques show the transition from "construction" to "manufacturing" that has already taken place in other industries.

-

Instrumentation & Controls

Reduce stress with proper on-line rotor temperature monitoring

On-line temperature monitoring of steam turbine rotors must be based on modeling thermodynamic processes—not direct temperature measurements. Good operating decisions can significantly extend the life of aging turbines, particularly those that are routinely cycled or operated at their maximum ramp rates.

-

Instrumentation & Controls

Water chemistry an important factor to consider for cycling HRSGs

Operators of combined-cycle plants that have been pressed into cycling service should make sure that the aqueous diet of their steam generators—especially heat-recovery steam generators—fits the plants’ more active lifestyle. Following are some tips for keeping your HRSGs’ water treatment regimen in tip-top shape. These prescriptions can keep the units vital longer and make them subject to fewer unexpected failures.

-

Instrumentation & Controls

DG interconnection standards remain elusive

The state of interconnection standards for distributed generation plants remains disconcerting to many prospective owners of such plants. IEEE 1547 has been in place for several years and appears to be the best option in a field of competing standards. But IEEE 1547 is an imperfect standard; it holds at least six holes. Here are some suggestions for filling them.

-

Instrumentation & Controls

Controlling shaft voltages

Contrary to public belief, the most common electrical phenomenon produced by a power plant’s steam turbines, turbine-driven compressors, and pumps isn’t sparks or lightning bolts. It’s static electricity. The physical effects of static electricity—greater vibration and higher temperatures—can damage bearings, shaft journals, couplings, and gears enough to cause a forced outage. A few inexpensive instruments in the hands of a well-trained technician can prevent "frosting" and "worm tracks" in your babbitt bearings. We’ll start the training right now.