Latest

-

Coal

Global Monitor (February 2008)

FutureGen picks Mattoon, Ill./Duke applies for first greenfield COL/PPL to work with UniStar on another COL

/Areva seeks NRC certification of its reactor/Mitsubishi also in line at the NRC/PV project shines in Nevada/SunEdison commissions Colorado PV plant/Big concentrating solar plant proposed/Super Boiler celebrates first anniversary/Small fuel cell uses JP-8 jet fuel/POWER digest -

O&M

Focus on O&M (February 2008)

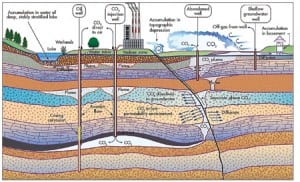

Survey captures industry’s carbon concerns; Sequestering coal plant emissions; Comparing mercury measurement methods

-

Legal & Regulatory

California constrains competition again

Given a chance to make a positive change in California’s wholesale generation market, the California Public Utilities Commission (CPUC) in December opted instead to maintain the state’s existing “hybrid” market model. That decision will further restrict meaningful opportunities for independent power producers (IPPs) and increase the likelihood that future generation will consist of utility ratebase […]

-

O&M

TVA’s Shawnee Fossil Plant Unit 6 sets new record for continuous operation

Shawnee’s new 1,093-day long-run record is a testament to the plant’s highly qualified and trained staff, excellent operations and maintenance processes, and the quality leadership required to keep all the moving parts pointed in the right direction. If running a power plant is a team sport, then the staff of Shawnee are in a league of their own.

-

O&M

Alliant Energy sweeps EUCG Best Performer awards

The Fossil Productivity Committee of the EUCG conducts an annual analysis of its member plants’ operating results and selects the Best Performer in the categories of small and large coal plants. For 2007, Alliant Energy’s Lansing and Edgewater Generating Stations took the top spots—the first time in recent history that a single utility claimed both awards.

-

Coal

Alstom’s chilled ammonia CO2-capture process advances toward commercialization

Carbon dioxide emissions aren’t yet regulated by the EPA, but it’s likely they will be soon. There are many technically feasible, but as-yet-undemonstrated ways to reduce the considerable carbon footprint of any coal-fired plant, whether it uses conventional or unconventional technology. One promising approach to removing CO2 from a plant’s flue gas uses chilled ammonium bicarbonate to drive the separation process.

-

Coal

Accelerating the deployment of cleaner coal plants

The dearth of commercial operating experience for advanced coal-fired facilities is forcing their early adopters and builders to use long development cycles and pay high costs for unique engineering design studies. A broad-based industry collaborative effort fostered by EPRI to address this issue is beginning to show results.

-

O&M

Who’s doing coal plant maintenance?

POWER has reported on several EUCG benchmarking studies over the past several years. This month we examine the maintenance staffing of 45 coal plants reported by 13 EUCG member utilities. If you benchmark your plants or fleet, as you should, some of the study’s results challenge what is considered conventional wisdom.

-

O&M

The case for cathodic protection

All fossil fuels carry some risk with their reward of an energy density that’s sufficient for producing electricity economically. For coal and natural gas, that threat is a fire or explosion. However, the risk of an explosion isn’t limited to gas-fired plants. Gas poses a threat to any plant that uses the fuel, even in small quantities for heating. Here’s an overview of what you should be doing to keep gas pipelines from corroding and exploding.

-

Distributed Energy

Aggregated backup generators help support San Diego grid

Last year, San Diego Gas & Electric tapped Boston-based EnerNOC Inc. to aggregate 25 MW of backup generators throughout SDG&E’s service area to relieve the grid when it’s stressed by peak demand for electricity. By combining stringent environmental controls with field-proven expertise managing distributed assets, EnerNOC has helped to improve grid stability in Southern California.