Thermal power plants, nuclear and fossil-fueled, rely on cooling water intake structures (CWIS) to withdraw water for rejecting waste heat. The CWIS serves as a critical interface between engineered systems and the natural environment, making it vulnerable to various external factors such as biological growth, water chemistry changes, hydraulic forces, drifting debris, and meteorologic events.

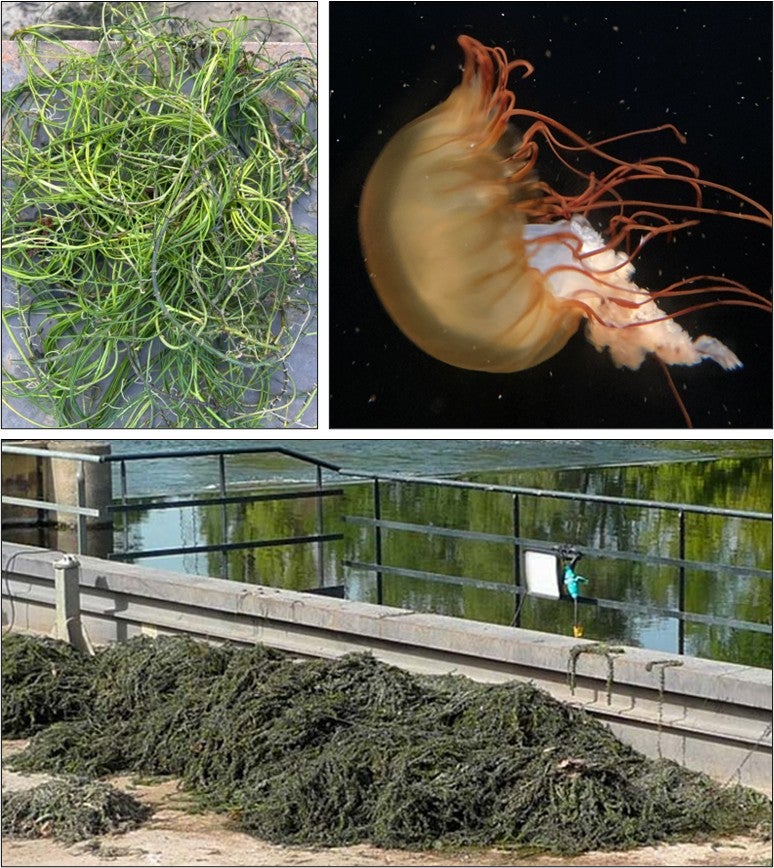

The primary operational challenge for operators of intake screening equipment is managing waterborne debris or aquatic life (Figure 1). Large debris influxes can occur episodically or seasonally and vary depending on the type of waterbody (such as reservoirs, rivers, lakes, or oceans). Increasing ecological variability, including extreme weather and biological responses to it, is intensifying these challenges. Long-term environmental shifts like changes in salinity, temperature, and species composition will further complicate management of debris influxes.

A second major challenge involves biofouling and corrosion of intake surfaces and materials of critical equipment. Unlike sudden debris events, these processes develop gradually but equally degrade availability, integrity, and reliability of the CWIS. Awareness and monitoring of both immediate and slow-developing threats increases facility preparedness and are essential for maintaining resilient operations.

While remote monitoring is common for primary plant equipment, CWIS monitoring remains limited and is typically focused on operational settings of equipment and monitoring only indicative parameters and visual inspections by field operators. Offline sensors may be relied on in some cases, but require manual data retrieval, and many intakes are physically distant from control rooms leading to an “out-of-sight, out-of-mind” mentality. Yet, failures in intake screening can cause disproportionate plant impacts including unplanned outages, damaged CWIS components, and operational and personnel safety risks. This justifies investment in real-time remote monitoring technologies tailored to CWIS.

Beyond daily operational concerns, long-term environmental changes driven by climate variability must be integrated into design basis and retrofit decisions. Parameters such as temperature, salinity, water levels, and debris loads are expected to become more variable and intense, affecting operating margins and ultimate heat sink performance. Continuous remote monitoring enhanced with artificial intelligence and machine learning (AI and ML) capabilities enables tracking of ultimate heat sink conditions and CWIS performance under evolving conditions and informs improved future designs.

The Importance of Being Informed

With increasing variability in source water quality and meteorology, CWIS are subjected to more frequent and severe challenges requiring stricter inspection and maintenance regimes. Historically, structural integrity was assessed during scheduled outages, and source waterbody monitoring was less systematic. Advances in sensor technology now enable continuous or near-real-time monitoring of both intake components and source water conditions. In addition, AI and ML can facilitate rapid background analysis of large datasets, delivering actionable insight to operators and maintenance teams, as well as trend monitoring over longer periods. Being well-informed leads to reduced downtime, better event management, fewer unplanned outages, increased generation revenue, and enhanced safety—especially critical for nuclear facilities.

The Institute of Nuclear Power Operations (INPO) highlighted in 2007 that inadequate environmental monitoring contributed to the impacts of intake blockages. Many plants lack the capability to remotely monitor CWIS water levels or traveling screen operations, focusing remote monitoring efforts instead on parameters like condenser backpressure. Improved monitoring of intake-specific conditions and the precursors to debris events is therefore necessary and, in many cases, overdue.

Assembling a Forecasting System for Debris Events

Debris events typically arise suddenly, prompting reactive measures to protect screening equipment. A forecasting system would provide operators the opportunity to adjust equipment settings, mobilize personnel, and plan for mitigating actions to avoid potential plant derates. It also allows operators to decide whether to continue operation if the verified debris loads will not overwhelm the equipment.

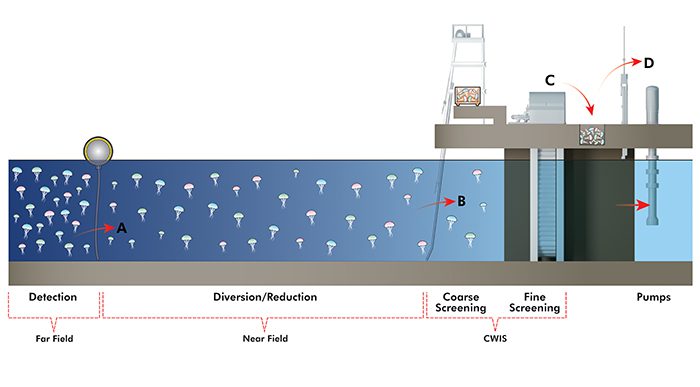

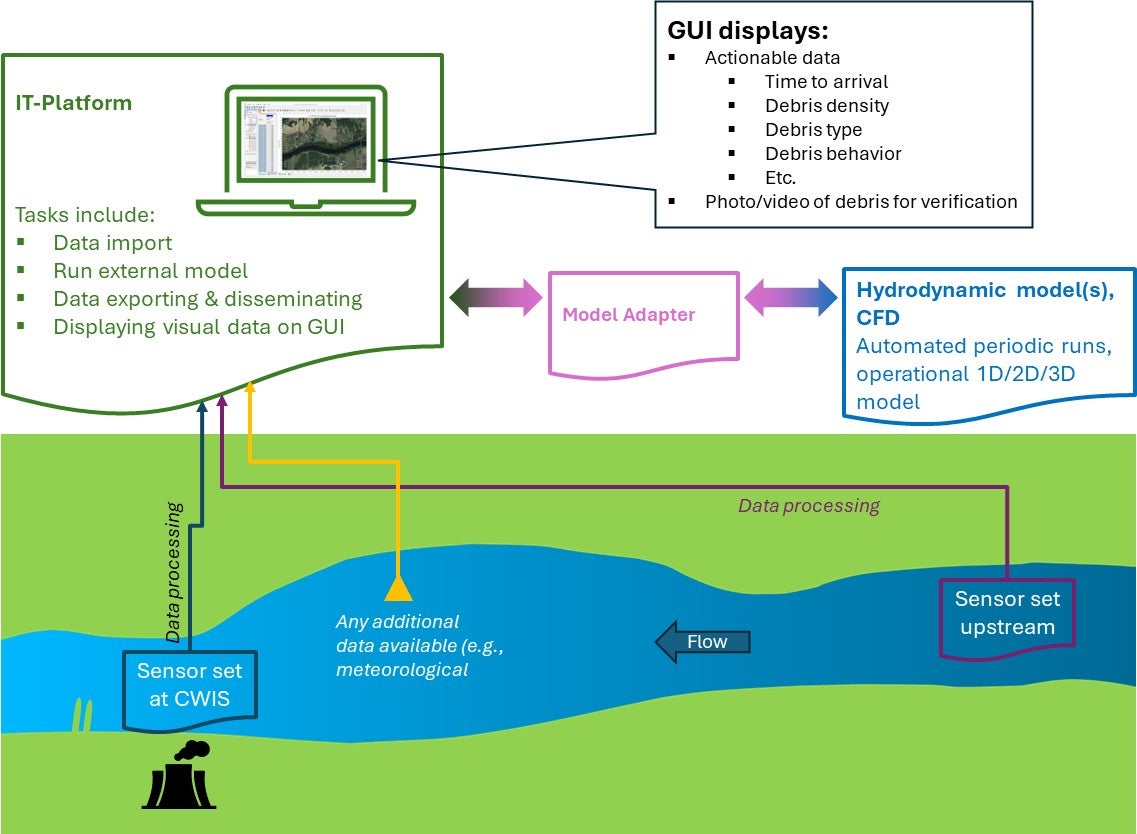

Such a system would combine real-time field measurements of abiotic and biotic parameters with hydrodynamic and hydraulic modeling to predict debris trajectory, speed, density, arrival at the intake, and duration of the event. A functional forecasting dashboard integrates sensor data and model outputs via a site-specific algorithm, issuing alarms based on thresholds validated by empirical sensor detection to minimize false positives. A forecasting system also presents the viewer with detailed, actionable information (such as time to arrival).

Forecasting tools range from highly site-specific models to robust platforms that are customizable across multiple sites. Publicly available oceanographic and meteorological data can be used to support routing and timing predictions.

The Electric Power Research Institute (EPRI) has published guidance, manuals, and best management practices on debris event forecasting and is currently conducting a multi-phase project that seeks to integrate in-situ sensors with hydrodynamic models and an information technology (IT) platform to provide real-time, actionable warnings supported by visual evidence such as photos and videos. Figure 2 provides a schematic overview of such a forecasting system.

Advanced Monitoring of Critical Debris Management Equipment

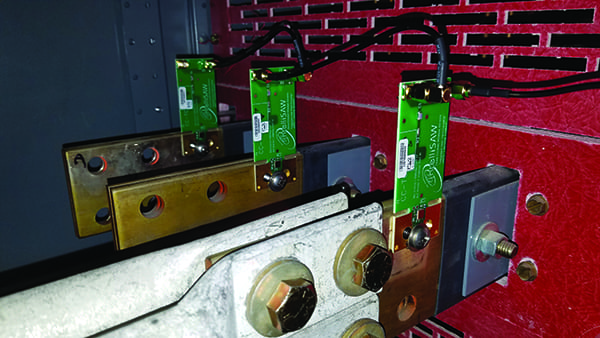

Increasing environmental variability and debris loads impact screen operation frequency and equipment availability and reliability. Operators seek remote sensors that are capable of tracking parameters of fine screen systems, such as:

- Water conditions including salinity, temperature, and water level.

- Number, duration, and timing of debris events.

- Debris load metrics measured by weight and volume over time.

- Preventative maintenance status.

- Operating hours.

- Screen rotation speeds and durations.

- Wear indicators such as chain condition and mesh integrity.

- Debris impingement and recovery rates.

- Spray wash pressure and efficacy.

- Debris disposal efficacy.

Continuous online monitoring approaches enable early detection of equipment degradation, reducing forced outages and maintenance costs. Relative to schedule-based maintenance, condition-based maintenance can result in savings.

Sensor suites can integrate data from programmable logic controllers where screen settings are controlled, other strategically located remote sensors, and AI/ML-assisted optical tools (including photos and videos). This comprehensive data can support both short-term readiness and long-term reliability assessments by correlating operational trends with environmental conditions.

Advanced Condition Monitoring of Submerged Components

Understanding equipment conditions requires collecting and trending operational data such as head differential alongside visual inspections of material integrity, corrosion, biofouling, and wear. Regular documentation of monitoring results and review of those results by team members ensure that preventative maintenance and any corrective actions are completed in a timely manner.

Industries such as offshore oil and gas, aquaculture, and shipping use underwater camera systems extensively. These systems, when coupled with AI and ML, enable automated object identification, size estimation, and abundance estimates. At CWIS, remote underwater cameras can also improve safety by reducing diver exposure and minimizing downtime by allowing detailed inspections during pump operations.

Stereo cameras and three-dimensional visualization techniques including point clouds and XYZ measurements enhance data richness, supporting informed decision-making for maintenance planning. For example, some underwater camera systems can generate very-high-resolution three-dimensional imagery that is sufficient to allow reverse engineering of replacement parts. However, the volume of data generated by advanced cameras necessitates intelligent edge computing to process and reduce data storage needs before cloud transmission.

Camera Systems for CWIS Inspections and Continuous Monitoring

Traditional dive inspections rely on helmet-mounted cameras, though they are limited by visibility. In addition, when divers are deployed, pump shutdowns are required for safety. Remotely operated vehicles (ROVs) offer alternatives but depend heavily on operator skill and risk tolerance, especially if the deployment is planned with pumps running.

Next-generation underwater cameras incorporate embedded AI and ML for automated analyses and image enhancement such as turbidity reduction. They generate higher-quality imagery enabling more accurate condition assessments and trend identification over time (especially for relatively slow processes of material degradation). Primary inspection focus areas for such advanced camera systems include:

- Biofouling, including quantitative coverage and biomass estimates, species identification, and live or dead condition assessment.

- Material integrity, covering surface condition, corrosion, and coating damage.

- Structural integrity, detecting deformations, fatigue-related anomalies, and impact damage.

Regular imaging of consistently submerged areas allows trend analysis using trained AI/ML algorithms that improve recognition of suboptimal conditions and enable timely interventions. Where environmental data are also being collected, observed trends in CWIS equipment condition can be correlated to long-term, climate change-related variations in water chemistry and temperature.

Beyond traditional, periodic inspections, advanced camera systems can be used for continuous monitoring of submerged intake equipment as well. For continuous monitoring, cameras are equipped with automated lens cleaning systems that use mechanical brushes or ultraviolet (UV) light to prevent fouling and maintain image quality. Continuous optical monitoring can allow assessment of:

- Debris particle sizes and density trends.

- Sedimentation buildup.

- Behavior of aquatic organisms and debris near screens.

- Debris passage and interaction with screens.

- Biofouling species coverage.

- Mesh occlusion percentages.

- Spray wash effectiveness.

- Surface anomalies such as corrosion and tubercles.

- Structural deformation.

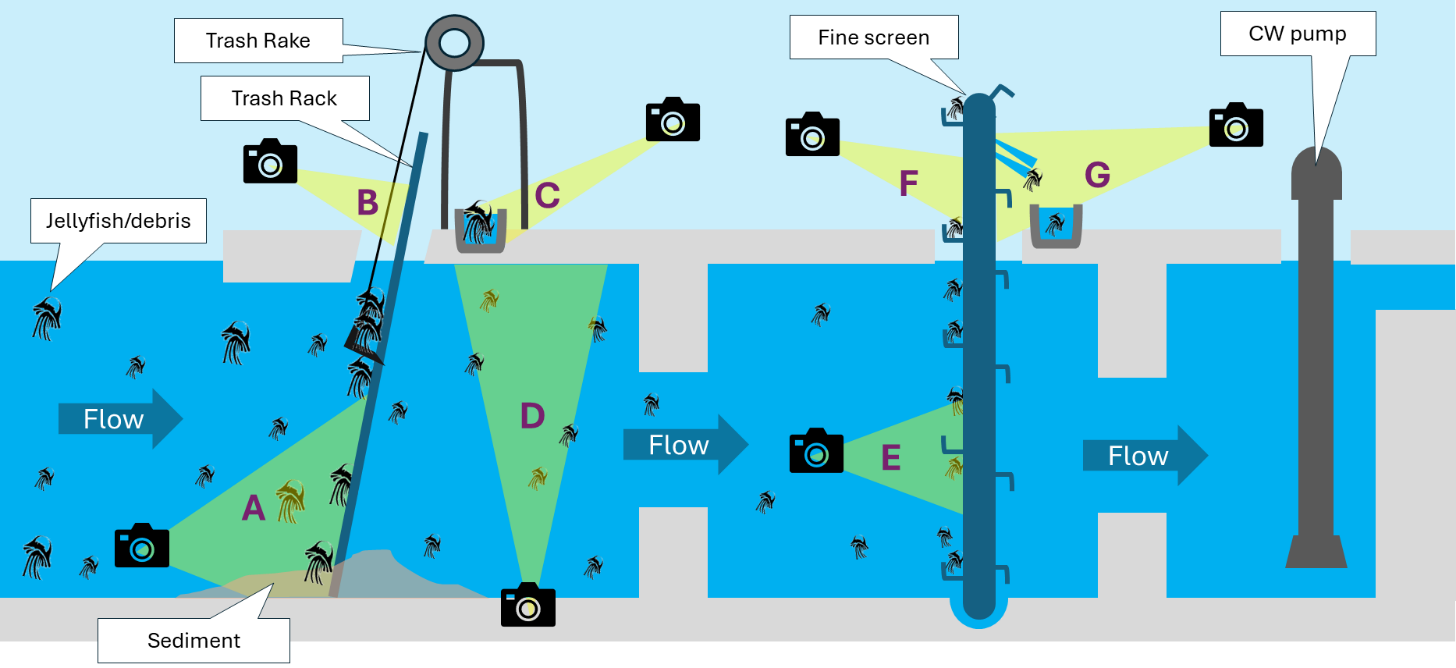

Alerts can be programmed to notify operators when thresholds are exceeded, facilitating proactive maintenance. Figure 3 provides an illustration of the areas of the CWIS and the screen components that could be continuously monitored with optical camera systems.

In this example, the areas monitored by cameras include:

- A. Looking at upstream surface of trash rack for passage/impingement of jellyfish/debris and sediment settlement.

- B/C. Looking above water surface at efficiency of removing material from the trash rack.

- D. Looking vertically through water column assessing density in front of fine screen.

- E. Looking at upstream surface of fine screen for behavior of jellyfish/debris and functionality of transport buckets.

- F. Looking above water surface at upstream surface of fine screen for efficiency of mesh and transport buckets to lift jellyfish/debris from the water.

- G. Looking above water surface at downstream side of fine screen and trough for efficiency of spray wash system to remove gelatinous material and other debris types from the mesh, transport efficiency in debris trough.

Ensuring Dependable CWIS Operation

Maintaining CWIS reliability and resilience is vital for safe and efficient thermal power plant operation amid increasingly challenging environmental conditions, both in the short and long term. Frequent, continuous monitoring enables early warning of adverse events, optimizes preventive maintenance scheduling, and keeps equipment in good operating condition so that it will function adequately when challenged during debris events.

Despite heavy instrumentation of most in-plant systems, the adoption of advanced monitoring at CWIS has lagged due to physical distance and perceived lower criticality. However, advances in sensors and AI-enhanced camera technologies now make it feasible and necessary to modernize CWIS monitoring.

Applying smart monitoring tools locally and regionally can reveal broader environmental trends, informing intake design improvements and operational strategies across the industry. This aligns with recommendations from INPO that emphasize improved readiness, better tracking of environmental conditions, and fitness evaluations to reduce intake screen unavailability, which remains the dominant failure mode.

Development of an integrated “Intake Reliability Tool” combining remote sensing, modeling, and AI-driven analytics would offer a practical path forward to meet these challenges and safeguard power plant operations.

—Maarten Bruijs is principal consultant with Pecten Aquatic, Timothy Hogan is principal consultant with TWB Environmental Research and Consulting Inc., Jonathan Black is a technical executive focused on aquatic resource protection with EPRI, and David Olack is a principle technical leader with EPRI.