Water

-

Coal

Potential Impacts of Closed-Cycle Cooling Retrofits at U.S. Power Plants

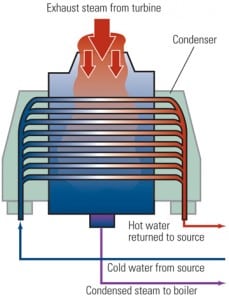

The Clean Water Act Section 316(b) rule changes regarding cooling water intake structures that are expected next year could affect up to 428 power plants, representing 1,156 individual units, according to the Electric Power Research Institute. Depending on plant size and the complexity of the retrofit project, retrofit capital costs could range from very low to over $500 million for large nuclear plants. The power industry total cost is projected to be over $100 billion.

-

Water

Evaluating Technologies to Address Proposed Effluent Guidelines

Upcoming revisions to U.S. federal effluent guidelines are anticipated to include new discharge limits for mercury and selenium in flue gas desulfurization wastewater, in addition to other potential revisions. Collaborative R&D is helping inform the rulemaking and is evaluating the cost and performance of technology options that might be used to meet the new targets.

-

Water

THE BIG PICTURE: Regulation Road

To view a larger version of this graphic, download the file here.

-

Water

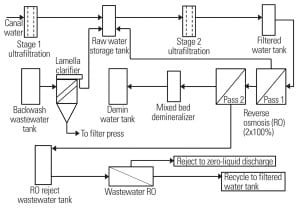

Design and Testing of a Water Treatment and ZLD System

In the following case study, Aquatech International Corp. discusses a water treatment system designed to minimize water usage and waste discharges, both liquid and solid, at a gas-fired combined cycle plant in California.

-

Water

Water Conservation Options for Power Generation Facilities

The electric power industry is a large water user and is dependent upon reliable water supplies. Adopting new water-conserving technologies for power production can help alleviate the impact of future water shortages. Several water use reduction technologies are available, each with different benefits and costs.

-

Water

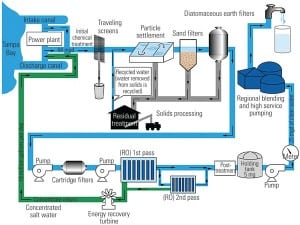

Water and Power: Will Your Next Power Plant Make Both?

In much of the developing world, two essentials are often in short supply: potable water and reliable electricity. Some countries have invested heavily in desalination and combined cycle technologies to simultaneously solve both problems.

-

Legal & Regulatory

Proposed Cooling Water Rule’s Ripple Effects

The U.S. Environmental Protection Agency (EPA) has a long history of making waves with the electric power industry because of its efforts to regulate the way thermal power plants construct and operate their cooling water intake structures (CWIS). These structures divert billions of gallons of water into power plants’ cooling systems and can injure or kill billions of aquatic organisms.

-

O&M

Plant of the Year: AES Gener’s Angamos Power Plant Earns POWER’s Highest Honor

AES Gener recently completed construction of twin coal-fired, 260-MW units in the electricity-starved desert of northern Chile that may serve as models for future hybrid-fossil plant designs. For meeting an aggressive construction schedule, integrating a 20-MW battery energy storage system, embracing desalination, using the first-of-its-kind seawater cooling tower in South America, and employing innovative financing methods, the AES Gener Angamos plant has earned POWER’s 2012 Plant of the Year Award.

-

Waste to Energy

Marmaduke Award: Combined Solar Technologies’ Hybrid Plant: Using Wastewater and Olive Pits to Produce Clean Water and Clean Energy

Combined Solar Technologies (CST) has designed, built, owns, and operates a water purification system located at the Musco Family Olive Co. facility in Tracy, Calif., that burns olive pits to purify highly saline wastewater through a distillation process while also producing electric power. For its pioneering approach, CST is the winner of POWER’s 2012 Marmaduke Award for excellence in plant problem-solving. The award is named for Marmaduke Surfaceblow, the fictional marine engineer and plant troubleshooter par excellence, whose exploits were chronicled in POWER beginning in 1948.

-

Gas

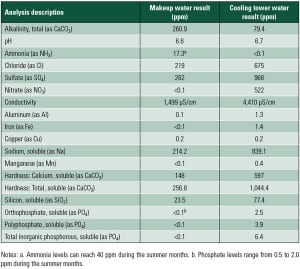

Performance-Based Cooling Water Treatment

A West Coast combined cycle plant that uses reclaimed water found that cycling 300 times a year caused disruptions to the plant’s cooling water chemical treatment program. The solution was a performance-based monitoring and control system that uses available plant operating data plus algorithms to measure corrosion rates and fouling factors, which in turn allows the plant to trim chemical feed rates so they correlate with a specified corrosion rate, rather than a suggested chemical residual.