O&M

-

O&M

Plan for the Worst: Insurance Insights

Imagine this scenario: Two separate power plants experience a bowing problem greater than 18 mils with a steam-turbine rotor. The turbines are from the same manufacturer and several repair options are reviewed. Management at both plants selects an innovative approach involving removal of a substantial amount of material, which is replaced with weld overlay and then machined to correct diameters and centerline of the balance piston area. One plant’s insurance company covers the repair, the other plant’s doesn’t. Why?

-

O&M

Fire Protection Options for Air-Cooled Hydroelectric Generators

Fire protection systems for air-cooled hydroelectric generators have several special requirements due to these generators’ unique geometries. This survey of options will help plant owners and operators make the best equipment selections for their plants and thereby avoid unexpected surprises.

-

O&M

Condenser Performance Improvement Through Innovative Cleaning and Leak Detection Technologies

One of the largest returns on investment a plant can achieve is the improved condenser performance that results from an effective condenser tube cleaning. Perhaps it is time to reevaluate your choice of cleaning technologies, establish an optimal cleaning schedule, and add routine air and water in-leakage surveys to your plant’s maintenance schedule.

-

O&M

Respect Your Refractory

Because refractory is out of sight inside the gas flow path of a steam generator and its auxiliaries, it’s also often out of mind. That is, until the refractory fails and causes a forced outage.

-

O&M

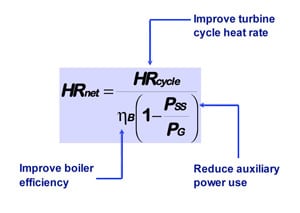

Power 101: Improving the Performance of Boiler Auxiliaries, Part III

Efficient boiler operation requires boiler auxiliary equipment to operate in harmony. In this third and last installment of our Power 101 series, we examine ways to decrease the auxiliary power requirements of boiler auxiliaries.

-

O&M

TECO’s San José Plant Models Safe and Sustainable Practices

In operation since 2000, TECO Energy Inc.’s 132-MW San José Power Station was the first coal-fired power plant built in Central America and is still the largest one. Used as a baseload plant, the facility successfully combines high availability with a business model that promotes sustainable environmental practices and a safe workplace.

-

O&M

Proper Sizing of Steam Header Drains Prevents Water Induction

Steam turbines convert the thermal energy in motive steam to rotating mechanical energy, and the generator converts that energy into electrical power. One important requirement for safe and reliable operation is preventing water induction in the steam turbine and avoiding water hammer in the steam piping system. ASME standards present the design guidelines for removing moisture from steam lines; this article explains a practical design process.

-

O&M

The Heat Is On at Arctic Air Base

Thule (“Two Lee”) Air Base is a 254–square mile base located in a coastal valley in the northwestern corner of Greenland, within the Arctic Circle. The base, the U.S.’s northernmost military installation, is nestled between mountains and surrounded by icebergs and glaciers as far as the eye can see.

-

O&M

Improve ACC Performance with Automated Pressure Washing

Beginning each spring and continuing through the fall, backpressure readings at Rosebud Operating Services Inc. indicated substantial drops in the condenser’s efficiency. Increased backpressure results in higher net plant heat rate and a corresponding measurable decrease in power generation.

-

O&M

Plant Safety: Learn from the Mistakes of Others

On January 27, the U.S. Chemical Safety Board (CSB) released a case study examining the causes of a heat exchanger rupture and ammonia release at the Goodyear Tire and Rubber Plant in Houston in 2008. Use these lessons learned to check your employee tracking system and to determine whether your plant has installed valves that […]