Gas

-

Gas

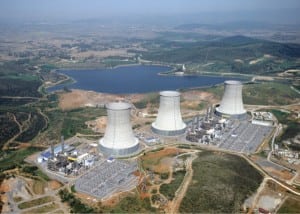

Top Plant: Adapazari Power Plant, Adapazari, Sakarya Province, Turkey

In 2010, the 2,310-MW Adapazari Power Plant achieved 99.8% availability, which is nearly 7% higher than the industry average and a global record in F-class gas turbine technology. The new turbine upgrade is helping ENKA Power bolster Turkey’s evolving economy by improving its energy sector’s efficiency and productivity.

-

Gas

Top Plant: Arvah B. Hopkins Generating Station, Unit 2, Tallahassee, Florida

Known for its progressive, pro-sustainability policies, the City of Tallahassee recently repowered a 30-year-old conventional steam plant unit, turning it into a new 300-MW facility. The utility redesigned the Arvah B. Hopkins Generating Station, Unit 2 as a 1 × 1 combined cycle plant in order to improve efficiency, switched the primary fuel from oil to natural gas, and thereby reduced fuel costs and emissions. The plant’s flexible design even will enable expansion to a 2 × 1 configuration when additional capacity is needed in the future.

-

Gas

Top Plant: Astoria II Combined Cycle Plant, Queens, New York

Managing construction of the 550-MW Astoria II Combined Cycle Plant in the midst of Queens, a densely packed New York City borough, required extensive off-site modular construction and a high level of logistical organization. Now the new Astoria II plant is operating successfully in conjunction with the Astoria Energy I plant as the largest natural gas–fired power plant in the Big Apple.

-

Gas

Top Plant: Emirates Aluminum Smelter Complex (EMAL), Al-Taweelah, Abu Dhabi, United Arab Emirates

The new 2,100-MW Phase 1 EMAL combined cycle power plant provides dedicated power with a high level of reliability to the Emirates Aluminum Smelter Complex, which is designed to be the world’s largest aluminum smelter upon completion. Located on the Persian Gulf, the gas-fired combined cycle plant uses seawater cooling towers to eliminate thermal stress on local marine life.

-

Gas

Top Plant: Irsching 4 Combined Cycle Power Plant, Irsching, Bavaria, Germany

The Irsching 4 Combined Cycle Power Plant has set a new world record in power plant efficiency with its new SGT5-8000H gas turbine. With an output of more than 578 MW and efficiency of 60.75% (net) achieved at a world record test run in May 2011, the plant demonstrates that climate protection, low-cost power generation, and flexible operation using fossil fuels can be attained simultaneously through technical advances. Due to its high efficiency, the gas-fired plant uses significantly less fuel and produces lower carbon dioxide emissions than traditional combined cycle plants.

-

Gas

Top Plant: Montoir-de-Bretagne Combined Cycle Plant, Montoir-de-Bretagne, France

The 435-MW Montoir-de-Bretagne gas-fired power plant is ramping up Gallic generation in the Loire-Atlantique region of western France. The plant’s innovative natural gas combined cycle technology offers high efficiency and low emissions.

-

Gas

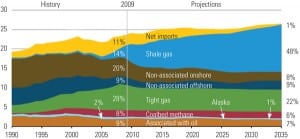

Global Gas Glut

Marcellus Shale gas has increased recoverable natural gas reserves in the U.S. by about a third over estimates prepared a few years ago. Europe is also exploring shale gas as an alternative to problematic Russian gas supplies and low proven natural gas reserves. POWER contributors in the U.S. and UK examine the comparative economic value, public acceptance, and political implications of these massive shale gas reserves.

-

Coal

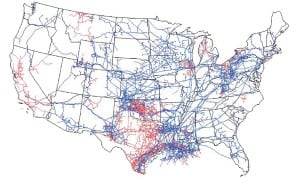

Best Practices for Natural Gas Line Cleaning

As barriers to new coal-fired generation expand and enthusiasm for nuclear plants wanes, the commissioning of natural gas–fired plants promises to increase. However, gas plants pose hazards, too. An explosion last year that was caused by unsafe use of natural gas to blow residue from a gas pipeline during commissioning of a gas-fired power plant has focused regulator and industry attention on finding safer alternatives for this task. Fluor shares its gas pipeline cleaning best practices.

-

Gas

Who Pays for Firming Up Variable Energy Resources?

The major economic hurdle for renewable power generation technologies continues to be substantial installation costs. But another cost is associated with continuous load-balancing, made possible by backstopping that variable generation with dispatchable generators that typically consume expensive fossil fuels. Bottom line: Who pays for the capacity firming or backstopping resources?

-

O&M

BIG PICTURE: Lights Out (Web Supplement)

A web supplement to the September issue with details of global power shortages.