Coal

-

O&M

Mercury Control: Capturing Mercury in Wet Scrubbers: Part II

In Part I of this two-part report ( COAL POWER, July/August 2007, p. 22), we introduced the integrated R&D effort by the U.S. Department of Energy’s National Energy Technology Laboratory (DOE/NETL) to improve understanding of the mechanisms of mercury (Hg) capture and retention in flue gas desulfurization (FGD) systems and the fate of Hg in […]

-

Coal

The Coal Pile: Steam Blast Rocks Big Apple

This July, an underground steam pipe near Manhattan’s Grand Central Terminal ruptured and spewed a scalding brown geyser of steam and debris higher than the nearby 77-story Chrysler Building. The blast, which injured 30 people, created a 40-foot crater at street level that swallowed a tow truck. A similar explosion in 1989 killed three people. […]

-

Coal

Speaking of Coal Power: BACT to the Future

This August, Peabody Energy’s 1,600-MW Prairie State Energy Campus project in Illinois won a major federal appeals court decision, removing the last obstacle to groundbreaking. The six-year regulatory review process ended with an unsuccessful Sierra Club challenge to the $2.9 billion project’s air permit. The decision is sure to reverberate across the nation, and I […]

-

O&M

The Coal Patrol: Mine Safety Deserves More Than Lip Service

Every step forward in underground U.S. mine safety in the 20th and 21st centuries has been on the backs of mangled and dead coal miners. That grisly observation is unassailable. Following the August tragedy at the Crandall Canyon mine in Utah that killed six miners and three would-be rescuers, the federal Mine Safety and Health […]

-

Coal

PRB Tech Notes: AmerenUE Teams with Charah and Home Depot to Market Ash for Concrete Mix

Burning Powder River Basin (PRB) coal can be a curse or a blessing, depending on your attention to the details of plant design and operations. One disadvantage of PRB coal combustion is the abundance of bottom ash and flyash generated as a by-product. Handling and properly disposing of the ash can be challenging and costly. […]

-

O&M

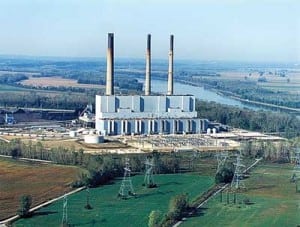

MidAmerican’s Walter Scott, Jr. Energy Center Unit 4 earns POWER’s highest honor

MidAmerican Energy Co. and its project partners are convinced that supercritical coal-firing technology’s inherently higher efficiency and lower CO2 emissions no longer come with a price: reduced reliability. Their Walter Scott, Jr. Energy Center Unit 4, the first major new supercritical plant in the U.S. in more than 15 years, is POWER’s 2007 Plant of the Year.

-

Coal

PSNH’s Northern Wood Power Project repowers coal-fired plant with new fluidized-bed combustor

The Northern Wood Power Project permanently replaced a 50-MW coal-burning boiler at Public Service of New Hampshire’s Schiller Station with a state-of-the-art fluidized-bed wood-burning boiler of the same capacity. The project, completed in December 2006, reduced emissions and expanded the local market for low-grade wood. For planning and executing the multiyear, $75 million project at no cost to its ratepayers, PSNH wins POWER’s 2007 Marmaduke Award for excellence in O&M. The award is named for Marmaduke Surfaceblow, the fictional marine engineer/plant troubleshooter par excellence.

-

Coal

Westar’s Lawrence Energy Center wins for not blinking on safety

It took Westar Energy eight years to upgrade the Lawrence Energy Center to burn Powder River Basin coal. Its zero lost-time accident record during the million-man-hour project is a testament to Westar’s commitment to workplace safety. Here’s your backstage pass to meet the PRB Coal Users’ Group 2006 Plant of the Year.

-

Coal

Navigating a carbon-constrained world

Scientific debate on the validity of global warming science continues, but the issue has yet had little impact on individuals. That impact is being negotiated in Washington, where a regulatory framework that would mandate reductions of greenhouse gases (GHGs) is taking shape. Legislative options under consideration would redefine what power plants must do-and not do-to […]

-

Coal

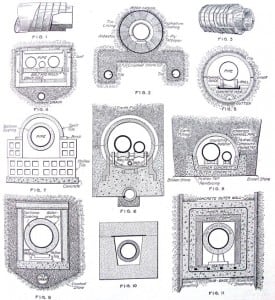

Dynamic classifiers improve pulverizer performance and more

Keeping coal-fired steam plants running efficiently and cleanly is a daily struggle. An article in the February 2007 issue of POWER explained that one way to improve the combustion and emissions performance of a plant is to optimize the performance of its coal pulverizers. By adding a dynamic classifier to the pulverizers, you can better control coal particle sizing and fineness—and increase pulverizer capacity to boot.