Coal

-

Coal

Optimizing Catalyst Performance Lowers O&M Costs

Santee Cooper’s Cross Station has implemented a catalyst optimization program that reduces catalyst replacement cost while maximizing catalyst performance. This case study illustrates the economic advantages of taking a holistic approach to optimizing unit catalyst performance by controlling slag, fouling, sulfur trioxide, and ammonium bisulfate—key factors that lead to premature shortening of catalyst life. With catalyst costing $2 million a layer and up, there is plenty of economic motivation to find ways to improve its life.

-

Coal

Power in India: Opportunities and Challenges in a Fast-Growing Market

India’s long-term annual economic growth rate is projected at over 7%, and the country is investing in its hydroelectric, nuclear, and renewable resources. However, the primary fuel used to produce electricity remains coal, and the government has ambitious plans to significantly increase coal-fired capacity. Those plans have been challenged by a number of unexpected factors that threaten to stifle India’s economic growth. India’s long-term annual economic growth rate is projected at over 7%, and the country is investing in its hydroelectric, nuclear, and renewable resources. However, the primary fuel used to produce electricity remains coal, and the government has ambitious plans to significantly increase coal-fired capacity. Those plans have been challenged by a number of unexpected factors that threaten to stifle India’s economic growth.

-

Coal

Innovation Required as Gas Displaces Coal

Panelists at the ELECTRIC POWER Keynote and Roundtable Discussion in Baltimore in May wrestled with a range of issues. But despite calls for a “balanced portfolio,” an “all-of-the-above” energy strategy, and predictions of “more changes in the next 10 years than in the last 100,” the focus of attention appears to be the decidedly mundane displacement of coal by natural gas.

-

Coal

New Technologies Advance Biomass for Power Generation

As U.S. utilities seek to increase the percentage of carbon-neutral biomass used in their generation portfolios, they must deal with a number of complex challenges unique to this fuel source. Several breakthrough technologies are poised to help promote greater use of biomaterials.

-

Coal

Clean Air, Dirty Water

Efforts by power producers to meet clean air rules mean that wastewater effluent streams now face revised EPA regulations. A skirmish involving a New Hampshire power plant could set the tone for the next battle over regulations.

-

O&M

Dusty Trail: The Movie

The season’s blockbuster includes white-hatted heroes, good-natured regulatory sidekicks, bar fights, and a lurking menace named Fugitive Dust.

-

Coal

Consortium Tests Alloys for Advanced Ultrasupercritical Boilers

A two-year project begun this April by Southern Co. and a consortium of partners including boiler vendors Alstom, Babcock & Wilcox, Foster Wheeler, and Riley Power; the Electric Power Research Institute (EPRI); and the Oak Ridge National Laboratory will gather data on the performance of alloy materials under advanced ultrasupercritical (USC) temperatures of about 1,400F. […]

-

Coal

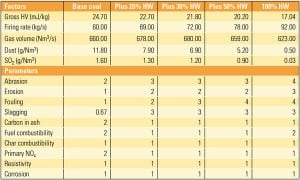

Safety Implications of Coal and Biomass Fuel Mixes

Practically everyone would agree that the energy policy of the U.S. is in a great state of flux. Not since the introduction of commercial nuclear power some five decades ago has our country come to such an energy crossroads. No matter what your political ideology, no one can refute that conventional coal-fired power plants are being paralyzed by recent and potential U.S. Environmental Protection Agency (EPA) regulations designed to cut the nation’s reliance on coal.

-

Coal

Denmark Extends Renewables Standard to 100% by 2050

Denmark’s parliament in late March agreed to a new energy strategy seeking to wean the country off oil and gas. It could result in the Nordic country cutting its greenhouse gas emissions 34% by 2020, compared to 1990 levels, and decreasing energy consumption by more than 12%, compared to 2006.

-

Coal

Callide Oxyfuel Carbon Capture Plant Retrofit Moves Forward

Oxyfuel technology has been retrofitted at a 700-MW coal-fired power plant in Queensland, Australia, and is now capturing carbon dioxide from one of the plant’s six steam boilers.