-

O&M

The Coal Patrol: Mine Safety Deserves More Than Lip Service

Every step forward in underground U.S. mine safety in the 20th and 21st centuries has been on the backs of mangled and dead coal miners. That grisly observation is unassailable. Following the August tragedy at the Crandall Canyon mine in Utah that killed six miners and three would-be rescuers, the federal Mine Safety and Health […]

-

Coal

PRB Tech Notes: AmerenUE Teams with Charah and Home Depot to Market Ash for Concrete Mix

Burning Powder River Basin (PRB) coal can be a curse or a blessing, depending on your attention to the details of plant design and operations. One disadvantage of PRB coal combustion is the abundance of bottom ash and flyash generated as a by-product. Handling and properly disposing of the ash can be challenging and costly. […]

-

Coal

Coal Plant O&M: How Switching to PRB Lowered O&M Costs

Lansing Board of Water & Light (LBW&L), which has generated electricity since 1892 and steam since 1919 in mid-Michigan, primarily serves the city of Lansing’s business district and all state government buildings in the downtown area. But one of the municipal utility’s plants, Moores Park, has an additional and very important steam customer: General Motors’ […]

-

Coal

Coal Plant O&M: SmartAsh Proves Its Worth

Every day, while driving to his job at PacifiCorp Energy’s Dave Johnston plant near Glenrock, Wyoming, Cole Harris used to wonder as he neared the station how opaque Unit 3’s stack emissions would look. Until a few years ago, Unit 3 (Figure 3) had trouble staying at or below opacity limits set by the state. […]

-

O&M

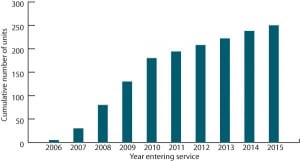

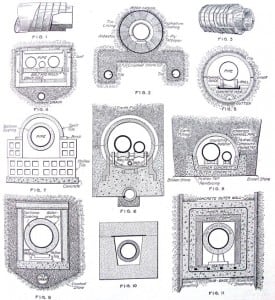

Plant Economics: The Impact of Shortages on FGD Prices

Since ratification of the Clean Air Act (CAA) in 1970, U.S. utilities have made steady efforts to install pollution control equipment to curb power plant stack emissions. The CAA Amendments of 1990 raised concerns at the time about the industry’s ability to install a large number of flue gas desulfurization (FGD) systems, or scrubbers, in […]

-

O&M

Mercury Control: Capturing Mercury in Wet Scrubbers: Part II

In Part I of this two-part report ( COAL POWER, July/August 2007, p. 22), we introduced the integrated R&D effort by the U.S. Department of Energy’s National Energy Technology Laboratory (DOE/NETL) to improve understanding of the mechanisms of mercury (Hg) capture and retention in flue gas desulfurization (FGD) systems and the fate of Hg in […]

-

Coal

The Coal Pile: Steam Blast Rocks Big Apple

This July, an underground steam pipe near Manhattan’s Grand Central Terminal ruptured and spewed a scalding brown geyser of steam and debris higher than the nearby 77-story Chrysler Building. The blast, which injured 30 people, created a 40-foot crater at street level that swallowed a tow truck. A similar explosion in 1989 killed three people. […]

-

O&M

Focus on O&M (August 2007)

Stop valves from leaking money / Integrating plant and equipment models / Pricing priceless knowledge

-

Is ratepayer funding of utility R&D outdated?

Southern California Edison Co. (SCE) is requesting regulatory approval to recover over $50 million from ratepayers to analyze the feasibility and cost of a "commercial-scale" clean hydrogen power generation (CHPG) facility that would gasify coal to fuel a combined-cycle power plant and sequester the associated carbon emissions underground. If the study demonstrates the CHPG technology […]

-

O&M

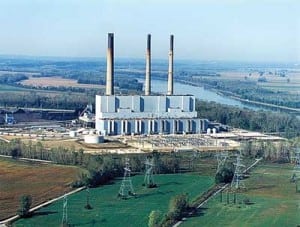

MidAmerican’s Walter Scott, Jr. Energy Center Unit 4 earns POWER’s highest honor

MidAmerican Energy Co. and its project partners are convinced that supercritical coal-firing technology’s inherently higher efficiency and lower CO2 emissions no longer come with a price: reduced reliability. Their Walter Scott, Jr. Energy Center Unit 4, the first major new supercritical plant in the U.S. in more than 15 years, is POWER’s 2007 Plant of the Year.

Search