Steam turbine technology is not stagnant. Advanced designs are incorporating innovations in blade design, advanced materials, precision manufacturing, and high-energy steam cycles, delivering significant efficiency gains.

As the world races toward decarbonization and increased renewable penetration, focus has largely shifted away from Rankine cycle plants. Yet, as challenges arise, from supply chain issues with combustion turbines to grid stability concerns with renewable integration, the steam turbine still dominates as a stable producer of big power. With grid demand projected to surge over the next decade, steam turbines will play an increasingly vital role. New technologies are pushing the boundaries of steam turbine efficiency to improve cost and support decarbonization efforts.

Efficiency and Decarbonization

Improving steam turbine efficiency has a direct impact on the amount of fuel utilized in a facility’s cycle, thereby reducing emissions and saving the operator money. Depending on the plant design and operating temperatures, a turbine efficiency increase of anywhere from 2% to 3% can result in an increase of 1% in plant efficiency. The International Energy Agency suggests a 1% efficiency improvement can reduce CO2 emissions by 2% to 3%. Consider global coal emissions of 15 gigatons of CO2 (GtCO2) in 2023. Improving average plant efficiency by 1% could result in an emissions reduction of up to 450 million metric tons (mt).

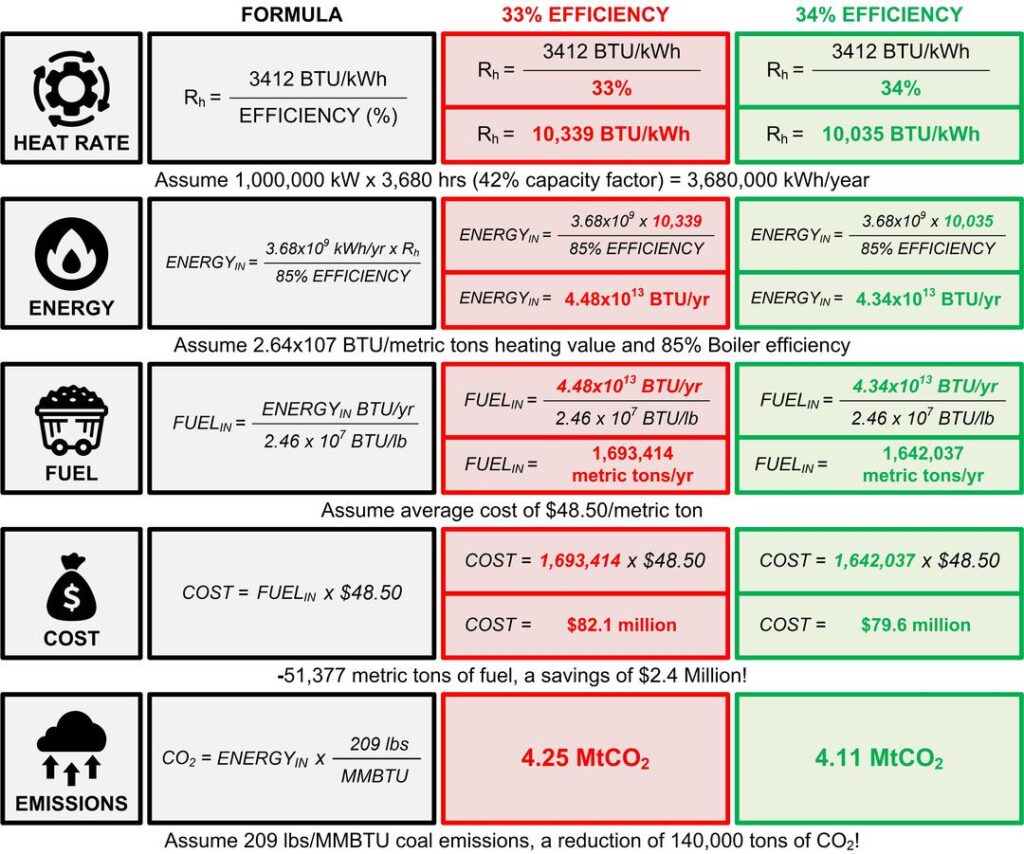

In addition to reduced emissions, the reduction in operating expenses (OpEx) can also be significant. Consider a 1% efficiency increase at a 1,000-MW coal plant. Increasing efficiency from 33% to 34% improves heat rate by about 3%. With a capacity factor of 42%, for example, the resulting reduction in coal consumption would be approximately 51,000 mt/year. At an average cost of $48.50/mt, the annual fuel savings would be $2.5 million, and at 209 lbs CO2/MMBtu, the emissions savings would be 140,000 tons of CO2 (FIgure 1).

For a similar natural gas–fired boiler, the fuel reduction could be as much as 510 million cubic feet (MMcf) per year. At an average price of $4.35/Mcf, the fuel savings could be as high as $2.2 million per year (assuming a 20% capacity factor).

Efficiency in Design

Design efficiencies at the turbine level focus on optimizing the efficiency of energy conversion and reducing losses in the turbine itself. Many manufacturers have made great strides in blade design, improving the aerodynamics of turbine blading, finding ways to increase the surface area of blades at various stages to improve energy use, and minimizing deformation and stress from vibration and temperature profiles.

One benefit of this method is the ability to retrofit existing units. This is not a new idea; the early 2000s saw many coal plants retrofitting turbines with improved components to reduce emissions and cost. The J.P. Madgett Station turbine upgrade in 2005 involved upgrading the original GE turbine with a new Siemens-designed low-pressure (LP) turbine, using advanced blade designs and larger last-row blades. The upgrade improved efficiency of the LP turbine by 10%, and also improved the high-pressure (HP) and intermediate pressure (IP) turbine by 8% and 2%, respectively.

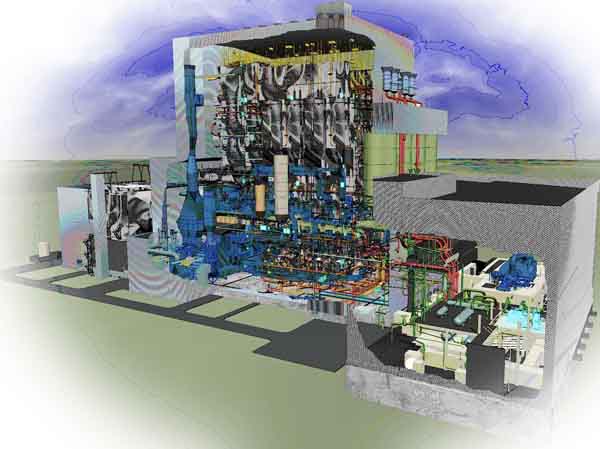

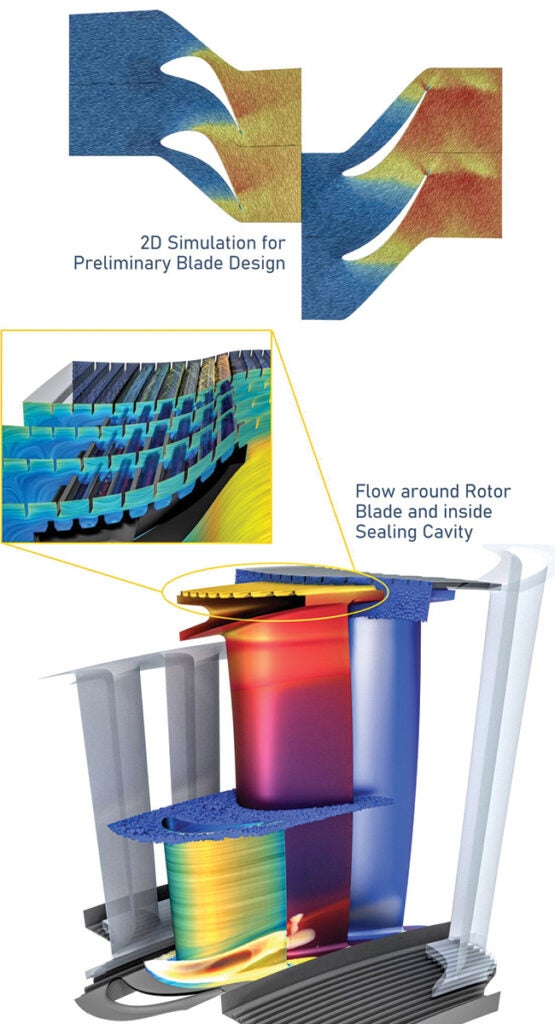

Companies like GE Vernova, Siemens Energy, and Mitsubishi Power have developed design improvements in blade aerodynamics, cooling, inter-stage leakage reduction, and moisture control to improve overall performance of large turbines, for both new and retrofit installations. Companies like German engineering firm B&B-AGEMA continue to apply computational fluid dynamics (CFD) and finite element analysis (FEA) to existing turbines to develop design improvements in flow stability, vibration, mechanical and thermal stress, and sealing. Utilizing advanced software, such as B&B-AGEMA’s Simcenter STAR-CCM+, high resolution simulations of multi-stage flow profiles have become standard (Figure 2).

Improvements in stage design, specifically in the loss mechanisms of leakage flow, have been proposed in multiple research documents. One notable concept focused on installation of “bladelets” into the leakage flow path at the rotor shroud to redirect leakage flow back into the main steam flow path at the same angle. Another design enhancement included the introduction of a “swirl breaker,” which in test models showed improved efficiency at each stage by reducing the mixing loss of rotor shroud leakage flow and mainstream flow.

Efficiency in Material and Manufacturing

Along with design improvements, advancements in materials and manufacturing methods have improved efficiency by reducing imperfections in components and improving stress profiles. These advances allow for direct improvements in efficiency in multiple ways, including:

- ■ Precise machining and advanced alloys support longer, larger blades to extract more energy from steam in the later stages of the turbine.

- ■ Alloys improve the erosion and corrosion resistance of blades, which improve lifetime efficiency.

- ■ Thermal barrier coatings (TBCs) and advanced alloys also reduce thermal expansion, allowing for tighter clearances, minimizing losses.

- ■ Advanced materials like nickel-based superalloys and advanced composites allow for higher steam temperatures and pressures since they can withstand higher temperature and mechanical stresses.

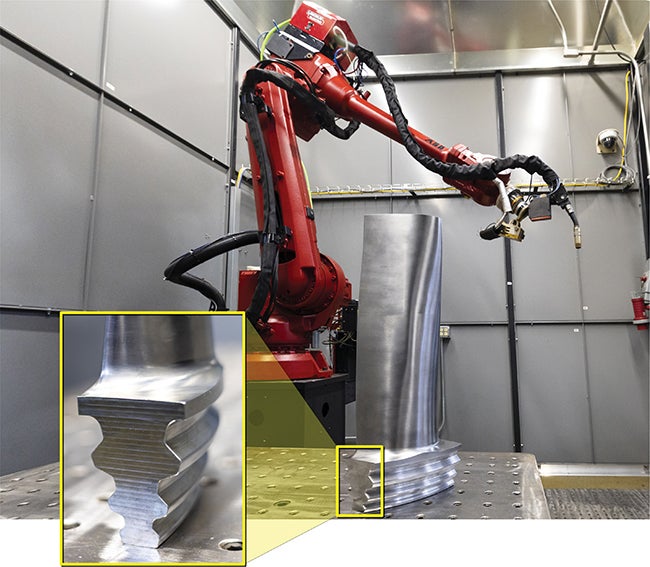

In addition, advancements in manufacturing can result in reduced repair and manufacture timelines, even with complex designs. In 2023, Oak Ridge National Laboratory and Siemens Technology became the first to “3D print” a utility-scale steam turbine blade using a process called wire arc additive manufacturing. An electric arc is used to melt wire in a process controlled by a robotic arm (Figure 3). Once printed, the part can be machined to final tolerances. Originally pursued to address supply chain delays in parts casted overseas, this process has the potential to improve production and repair capabilities. 3D printing could prove invaluable to the retrofitting process, combining advanced design techniques with turbine specific manufacturing to improve retrofit capabilities at reduced cost and timelines.

While 3D printing is not a common method of mass production of turbine blades, methods like selective laser melting (SLM) and electron beam melting (EBM) allow the manufacture of blades with complex internal structures (such as internal cooling channels), complex geometries, and reduced weight. Single-crystal casting and advanced machining, such as five-axis CNC (computer numerical control) and electrochemical machining (ECM), can achieve ultra-precise surfaces and structures with tolerances less than 0.1 millimeter.

Efficiency in Advanced Cycles

Material and design advancements are often a step in the process of improving efficiency by increasing energy utilized by the turbine to perform actual work. Efficiency can also be improved by increasing the energy applied to the turbine. By increasing operating temperature and pressure (supercritical or ultrasupercritical) the Carnot efficiency can be increased. These advancements require changes to the design of the plant itself, not just the turbine. By increasing steam temperature, the Carnot efficiency of the cycle is increased (higher differential between hot and cold side of the engine) and net efficiency can approach 50%. As part of these upgrades, advanced controls and reheat systems in the turbine complex can be utilized to increase turbine efficiency even further.

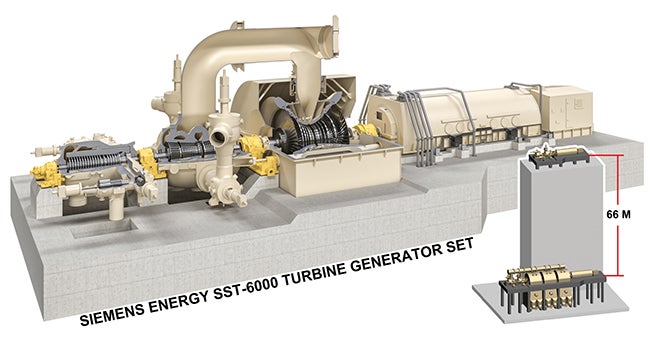

Facilities like Pingshan II in China, in operation since 2022, (49% unit efficiency, operating pressure 4,700 psia) utilize these advanced materials and advanced ultrasupercritical (A-USC) steam turbine designs. Pingshan II was the first implementation of a “split train” turbine, referred to as an elevated turbine generator (TG). The cross-compound turbine set utilizes Siemens Energy’s SST-6000 turbine design, similar to that shown in Figure 4. The design consists of an HP and IP1 turbine and generator located at an elevation near the boiler steam outlet, and an IP2 with three LP turbines (LP1–LP3) and associated generator set located at the “ground” level. The elevated HP turbine reduces heat losses to the HP turbine. However, there is a trade-off in the increased length of secondary reheat piping that must be accounted for.

Overall Efficiency

Power producers navigating rising energy demand, supply chain constraints, and decarbonization goals can rely on steam turbine advancements to ensure energy security and grid reliability. Innovations in blade design, advanced materials, precision manufacturing, and high-energy steam cycles enable efficiency gains that can deliver considerable savings—realized both in OpEx savings of millions in fuel costs and emissions savings of millions of tons of CO2. Proven retrofits, like J.P. Madgett Station, and innovative designs, such as Pingshan II, prove the steam turbine still has a place in clean energy production. By investing in these technologies, users can meet the challenge of rapidly expanding energy demand while pursuing decarbonization goals.

—Derek Meier (dmeier@fossilconsulting.com) is a senior training specialist with Fossil Consulting Services Inc.