Solar dominates new energy generation in the U.S., accounting for 69% of new capacity additions in Q1 of 2025. But although most of this added capacity comes from utility-scale projects, the engineering labor force hasn’t scaled to match this demand. Only a limited number of qualified engineers, particularly those with experience as Engineers of Record (EORs), can support the complexity and speed required for current utility-scale solar projects.

As project sizes grow and timelines compress, gaps in engineering capacity are leading to costly redesigns, delays, and missed deadlines. Developers and EPCs increasingly find themselves held back by teams unable to keep pace with the shifting technical and regulatory requirements of utility-scale execution.

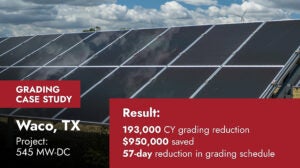

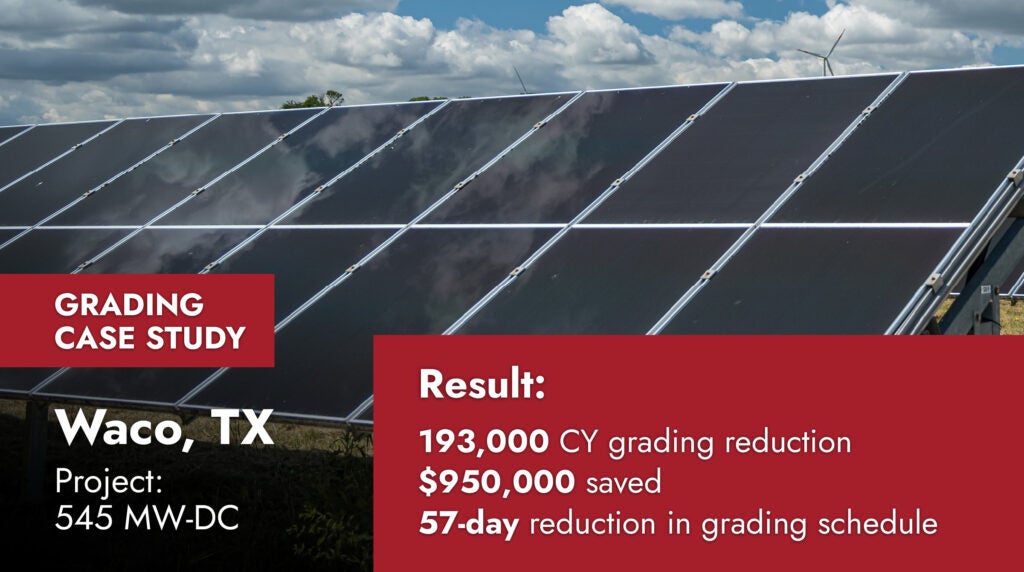

The Cost of Experience Gaps: $950,000 on a Single Project

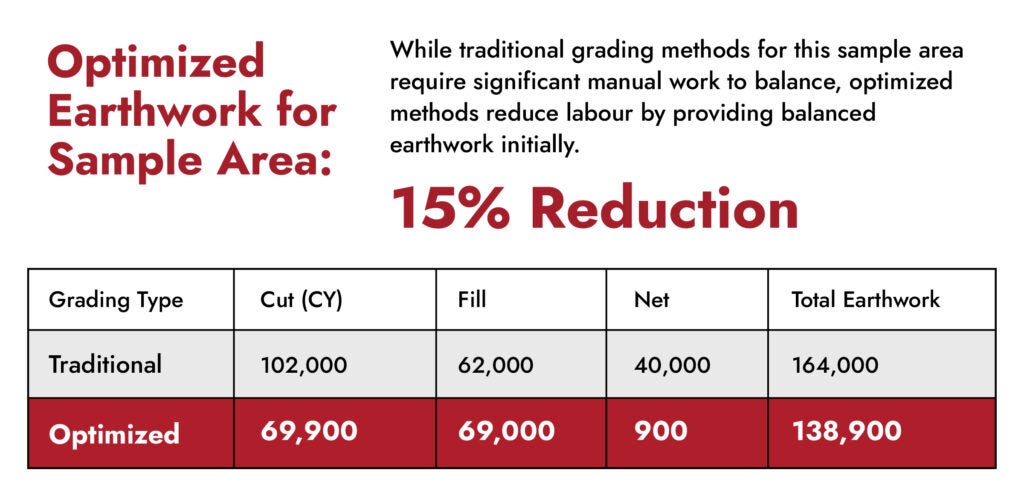

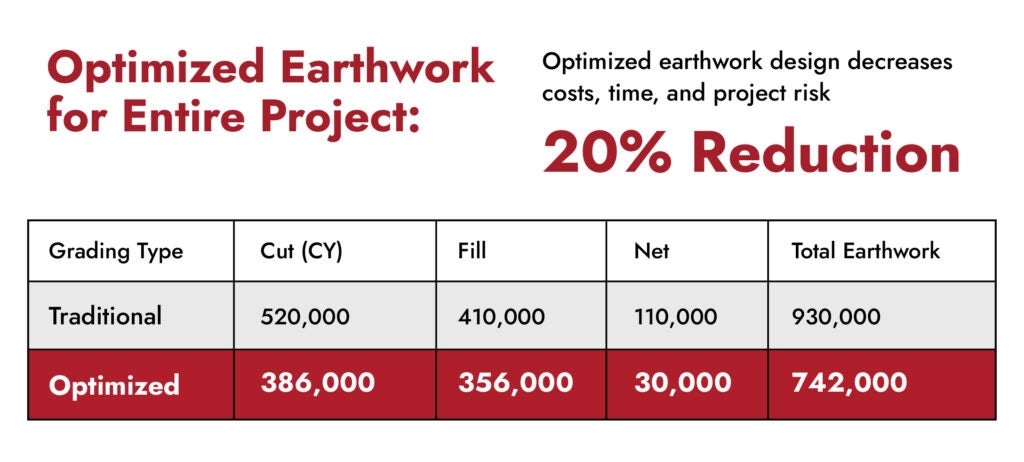

Engineering issues don’t just inconvenience project schedules; they directly impact financial viability. For instance, civil construction costs in utility-scale solar can vary dramatically based on site conditions. Grading presents one of the most significant cost risks, ranging from $4 to $5 per cubic yard to, in some cases, up to $15/yard. For large projects, earthwork costs often exceed half a million cubic yards.

COMMENTARY

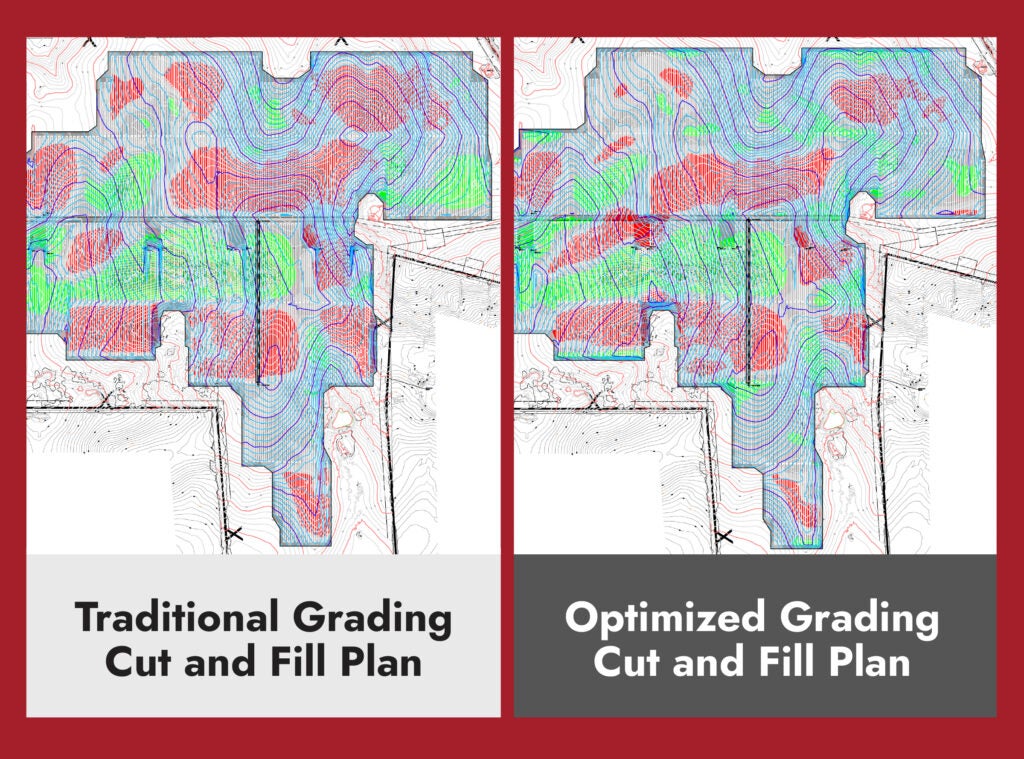

One recent large-scale project in Central Texas drove this point home for me. I was reviewing another engineer’s civil plan set, which included over 650,000 cubic yards of array grading – roughly the volume of 1.5 Walmart Supercenters. This plan would have cost the developer an estimated $3 million in earthwork.

After reevaluating the design, I was able to reduce grading by 193,000 cubic yards without changing tracker tolerances or grading requirements. These modifications cut over $950,000 in costs and shortened the construction timeline by 57 days, reducing erosion risk and allowing for earlier seeding.

This article is part of POWER’s annual special edition published in partnership with the RE+ trade show. This year’s event is scheduled for Sept. 8-11, 2025, in Las Vegas, Nevada. Click here to read the entire special issue, and if you’re attending RE+, be sure to connect with the POWER team at our booth on Venetian Level 1—V3046.

That’s more than $1,700 saved per MW, simply because I was able to draw upon an unusual amount of experience designing utility-scale solar. But this situation is far from unique: there’s a massive pipeline of utility-scale solar projects, and not enough engineers with the industry experience to design them with an expert eye on cost efficiency and timeline reduction.

Smarter Workflows for Smarter Project Delivery

Some engineering teams are implementing digital platforms that more efficiently align civil and electrical workflows to meet project deadlines, reduce unnecessary costs, and avoid redesigns.

In my experience, two types of tools are showing particular value:

Project Management Dashboards—While project management dashboards aren’t rare, it’s much less common to find them built specifically for utility-scale solar engineering teams, based on standard PMI (Project Management Institute) principles.

These dashboards, such as Castillo Engineering’s PMO 360, give developers and EPCs real-time visibility into design status, delivery timelines, pending actions, and critical path risks. With centralized access, teams can respond to delays or updates quickly, avoiding common pitfalls like silos and communication breakdowns.

Utility-Scale Solar Design Optimization—If there’s an experienced solar engineer on your team, involve them in creating an internal design software for less experienced team members.

These tools automate repetitive grading and electrical design tasks, allowing engineers to scale productivity while having more time to carefully analyze and modify designs. They also help improve quality control by serving as a hub for institutional knowledge and helping standardize field-informed best practices.

A tool developed and used in the Central Texas project incorporates point-to-point surface analysis to reduce grading volumes without impacting tracker tolerances or buildability. Such systems help experienced engineers work faster without sacrificing quality, and junior engineers build experience and skills in utility-scale solar while avoiding unnecessary costs and delays for their current clients.

If developed in close collaboration with engineers who have deep expertise in the field, these tools have shown significant impact on project schedules, field execution, and material cost reduction.

Supporting Field Teams with Practical Solutions

Field performance also shapes how engineering deliverables are judged. Civil grading tools designed with field teams in mind reduce not only earthwork, but also on-site rework and installation confusion. By accounting for practical construction tolerances, topographic anomalies, and erosion controls, these designs reduce costly micro-adjustments in the field and improve morale among field crews.

Another benefit: the earlier seeding and vegetation can begin, the more erosion risk is mitigated. With extreme weather events on the rise, that extra protection is essential for environmental compliance and long-term site stability.

A Scalable Approach for a Tight Labor Market

Tools alone don’t solve the industry’s labor challenge. For a long-term solution, we as an industry need to actively increase awareness of and access to high-quality engineering programs for potential talent.

But for today’s projects, tools do help scale the expertise of the engineers available. By automating low-value tasks and embedding years of institutional knowledge into digital workflows, engineering teams can serve more projects without sacrificing quality.

Developers benefit through more predictable timelines, improved coordination with EPCs, and lower execution risk. EPCs gain easier plans to interpret and execute, minimizing rework and improving the bottom line. For all parties, better systems mean fewer surprises and more projects delivered on time and on budget.

As the industry moves toward gigawatt-scale portfolios, scaling engineering capacity without compromising quality is no longer optional. Standardized, intelligent tools offer a practical and proven way to close that gap—and meet the next decade of utility-scale solar demand head-on.

—Brett Beattie, director of Civil Engineering at Castillo Engineering, is a licensed civil P.E. with more than a decade of engineering experience, specializing in optimizing solar civil design and constructability for utility-scale projects across North America.