The first effluent limitation guidelines update since 1982 is game-changing for many U.S. power plants. This unfiltered look at the rule and its nuances will help you understand how each component affects your plant and presents the five steps you need to take now to be on pace with the compliance timeline.

The U.S. Environmental Protection Agency’s (EPA’s) first update to the Steam Electric Power Generating Effluent Guidelines (commonly called effluent limitation guidelines or ELGs) since 1982 changes the way many power plants will operate in the future. The complex rule, coming in at a staggering 311 pages, covers a lot of ground. But the main focus falls on coal-fired power plants and integrated gasification combined cycle (IGCC) power plant wastewaters.

To grasp the impact of the rule at your plant, it’s important to know the history of the rule and the reasoning behind some of its nuances. That’s the logical start. Next you need to understand the latest update’s six main focus areas and how they apply to your facility. Once you’re up to speed on the rule itself, it’s time to take a hard look at the five steps you need to take now so your plant is ready for compliance, which could be as early as three years down the road.

The Update

It’s been a decade since the EPA first identified the power industry’s ELGs for study and a potential update. And on September 30, 2015, after 10 long years of studying, surveying, and debating, the EPA administrator signed the final ELGs rule for the steam electric power generating point source category and submitted it for publication in the Federal Register. The result? Lots of expected updates and a few surprising changes.

Here’s the brief background of this new rule. The steam electric power generating point source category ELGs rule regulates wastewater discharges from fossil- and nuclear-powered steam generating plants whose primary purpose is to generate electricity for distribution and sale, and that discharge to a surface water body via a National Pollutant Discharge Elimination System (NPDES) permit (direct dischargers) or discharge to a publicly owned treatment works (POTW) via a pretreatment permit (indirect dischargers).

The ELGs are technology-based regulations, which means the limitations set by the EPA under this rule are established based on what is achievable given the implementation of a certain treatment technology the agency selects as a basis.

Although nuclear and combined cycle power plants fall into this ELG category and are subject to this rule, the primary focus of the EPA update is coal-fired power plant and IGCC power plant wastewaters—particularly the wastewaters from these facilities associated with flue gas air pollution control systems or solid waste handling systems. Given that a number of these wastewater sources weren’t commonly used when the rule was last updated 33 years ago, many of these wastewaters were regulated as low-volume wastewaters. Now that these wastewaters are commonplace sources, a major intent of the update is to remove them from the catch-all category of low-volume wastewater and establish separate regulation of each using its own set of limits and treatment technology basis.

Six Focus Areas: What’s Changed and What Hasn’t

The 2015 ELGs update focuses on six power plant wastewater streams:

■ Flue gas mercury control (FGMC) system wastewater

■ Bottom ash transport waters

■ Fly ash transport waters

■ Flue gas desulfurization (FGD) wastewater

■ Coal combustion residuals (CCR) leachate

■ IGCC wastewater

Although additional regulation of nonchemical metal-cleaning wastes was proposed in the draft version of the rule, the EPA reserved this category of wastewater for future consideration. That decision was based on comments received from the industry and a general lack of data on the waste stream. Regulators will still be expected to use their best professional judgment when determining limits for discharge of these wastewaters.

The first three ELG updates ban FGMC wastewaters, fly ash transport waters, and bottom ash transport waters from being discharged to surface water bodies or POTWs.

FGMC wastewaters include any “process wastewater generated from an air pollution control system installed or operated for the purpose of removing mercury from flue gas.” This refers to the sluice or transport waters used to transfer the mercury adsorbent (usually activated carbon) from the collection hoppers to an impoundment. In the previous version of the rule, these wastewaters were included as low-volume wastewaters. Now they’re one of the streams (along with FGD wastewater, IGCC wastewater, and CCR leachate) being removed from the low-volume waste category to be regulated individually. In the final rule update, FGMC wastewaters are a stand-alone category. The EPA set dry handling systems as the technology basis for regulation and established a zero-discharge policy for new and existing sources generating this wastewater stream.

Bottom ash and fly ash sluice or transport waters are also zero-discharge streams under the updated ELG rule. Fly and bottom ash transport systems will need to be converted to the EPA technology basis options of dry handling or closed loop systems—or use other alternatives that do not necessitate discharge of ash transport wastewaters. However, the EPA did allow for ash transport waters to be reused within the plant on a very limited basis as an alternative to system conversion. Plants that reuse ash transport wastewaters as FGD scrubber makeup water may continue to do so.

It’s worth pointing out that the zero-discharge restriction for bottom ash systems only applies to those conveyance systems where water is the conveying medium for the ash. It doesn’t apply to bin overflow or bunker wastewater from bottom ash drag chain conveyance systems; this wastewater is still classified as a low-volume waste stream under the updated rule (Table 1).

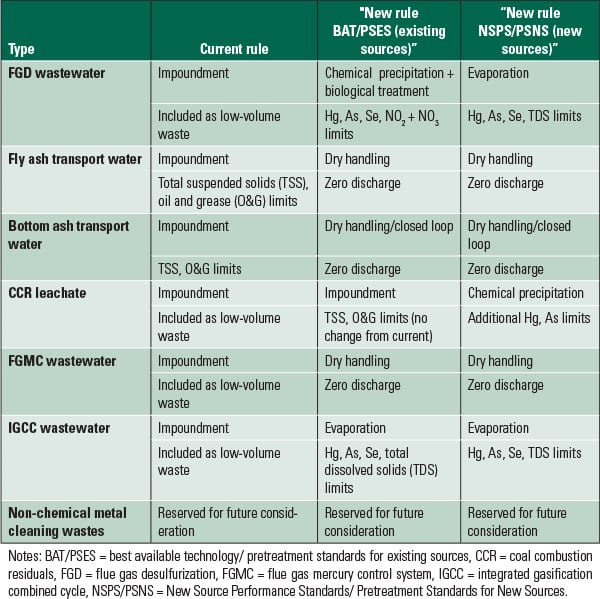

|

|

Table 1. Summary of technology basis and limitations for new effluent limitation guidelines (ELGs). Source: HDR Inc. |

For IGCC wastewaters (like sour waters and grey waters) produced during the generation of synthesis gas from coal or petroleum coke fuels, the EPA has identified thermal evaporation equipment as the technology basis. Most existing IGCC facilities already use this technology to handle their wastewater streams, so the EPA’s technology basis selection isn’t a big surprise. The updated ELGs set numerical limits on mercury, selenium, arsenic, and total dissolved solids (TDS) content for any discharges of the treated wastewater stream (see Table 2 for a summary of the numerical limits) from any existing generators, as well as any new generators constructed in the future.

With the EPA’s issuance of the CCR rule earlier this year and its ultimate classification of CCR materials under Resource Conservation and Recovery Act (RCRA) Subtitle D, the question of whether to close CCR impoundments has been a hot topic at almost every coal-fired power plant. The ELG update clarifies how plants should handle treatment of their leachate, enabling plants to finalize compliance or closure plans.

The update does not change the technology basis for treatment of CCR leachate from existing sources. Leachate from existing CCR impoundments and landfills can continue to be treated via impoundment and is regulated with numerical limits for total suspended solids (TSS) and oil and grease (O&G) only. But leachate from new CCR landfills or impoundments constructed after the rule implementation date will have to meet additional numerical limits for arsenic and mercury prior to discharge to a surface water or POTW. And the EPA has established chemical precipitation systems as the technology basis for new CCR leachate sources.

FGD wastewater is the most complex section of the new rule. As plants develop compliance plans, this area will likely demand the greatest level of engineering design and planning. FGD wastewaters include not only purge waters but also liquid waste streams generated from any associated solids separation or dewatering processes. The rule includes big changes to requirements for treatment prior to discharge of this wastewater stream for both new and existing sources.

Looking back to the June 2013 draft version of the rule, the EPA went in a different direction for a couple of areas. After reviewing comments, the numerical limits proposed for wastewaters treated by chemical precipitation followed by biological treatment were adjusted to be more consistent with results users are currently achieving. Additionally, the new rule also changed to require different technology bases for new versus existing sources. Based on investigations, the EPA has established the technology basis for setting standards for FGD wastewater from existing generators as chemical precipitation followed by biological treatment to meet the numerical limits specified for mercury, arsenic, selenium, and nitrate plus nitrite (see Table 2).

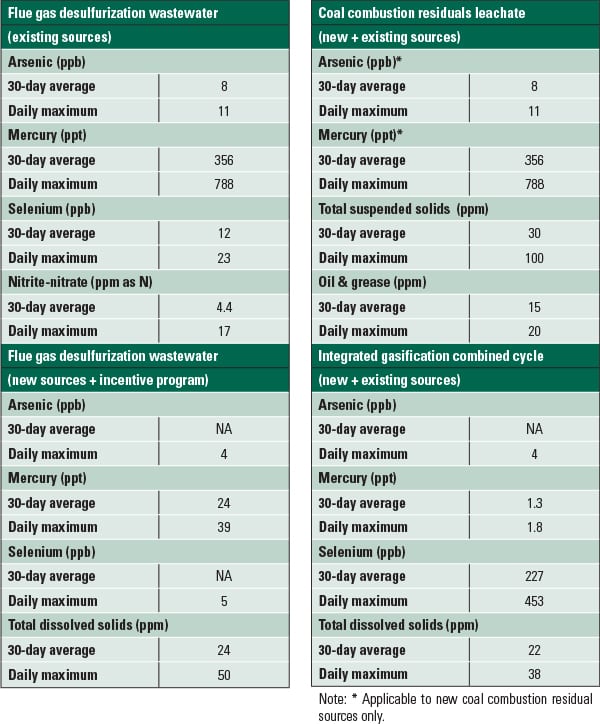

|

|

Table 2. ELG numerical limits. Source: HDR Inc. |

For existing sources, the EPA has also offered an optional incentive program. The incentive extends the ELG compliance deadline to December 31, 2023, regardless of permit renewal date for any existing FGD wastewater generators who voluntarily accept a more stringent technology basis for treatment of FGD wastewater—vapor-compression evaporation—and agree to be subjected to numerical limits for mercury, arsenic, selenium, and TDS commensurate with this treatment technology.

Vapor-compression evaporation also was selected as the technology basis for regulation of FGD wastewater for any new sources constructed after the implementation date. So those same numerical limits specified for the incentive program will be mandatory for new generators of FGD wastewater. Though the limits and technology basis may seem extreme, if a plant has other stringent water quality based effluent limitations (WQBELs) as part of its NPDES permits, the incentive, coupled with the additional time to comply, might make sense.

The Fine Print

The six focus areas addressed above cover the new rule’s headlines. Now for the details like legacy wastewaters, anti-circumvention provisions, and fundamentally different factors (FDF).

Legacy Wastewaters. Plants grappling with decisions related to the future of their CCR impoundments, as well as plants slated for decommissioning, have been concerned about regulation of legacy wastewaters. According to the EPA, legacy wastewaters are waters generated prior to the new rule’s implementation date, or the effective date of the plant’s permit update, and stored onsite (usually in an impoundment). Legacy wastewaters won’t be subject to the new ELG rule, which comes as good news for many plants. Legacy wastewaters generated prior to the effective date of the new permit (such as FGD purge or ash transport waters stored in an impoundment) will only be subject to the discharge limits in place at the time they were generated. This provision significantly helps environmentally conscious plants that have chosen to close CCR impoundments or decommission older coal-fired units.

Anti-circumvention Provisions. Many plants have made great strides in optimizing plant water usage over the past decade. So when the draft rule’s anti-circumvention provisions (which were aimed at preventing plants from using dilution as an aid in meeting proposed numerical limits) minimized opportunities for reuse and recycle of certain wastewaters, many plants were concerned the provisions would undo a lot of progress. In the final version, the EPA eliminated some of the restrictions, including mandatory internal monitoring points.

To avoid massive in-plant flow segregation for combined wastewaters (such as FGD wastewater combined with cooling water in a plant outfall) the new limits can instead be applied in a mass-based fashion, calculated by multiplying flow by concentration limits. A combined waste stream formula to adjust limits to account for the dilution factor can be established with regulatory agencies. But no internal recycle of zero-discharge wastewater streams is permitted under the final rule, with the exception of ash transport waters used as FGD scrubber makeup.

For wastewater streams with numeric limitations under the new rule, the numerical limitations were determined using long-term average effluent values and variability factors to account for variations in treatment system performance. The long-term average values used by the EPA are listed in tables as part of the preamble to the final rule and were not meant to be interpreted as permit limits but as a proposed design basis for specification of treatment systems to help plants consistently meet real numerical limits.

Fundamentally Different Factors. If your plant has significantly different systems from those used to establish the ELG rule—such as a once-through FGD system—your plant can apply for an FDF variance. This means the EPA, working together with the state, can set different standards for the ELG rule on an individual existing discharger if its system design is fundamentally different from the design types used to establish the ELGs. Buy-in from the state and other permitting authorities, as well as the EPA, is necessary for a variance to be granted, but it’s an option to pursue if your system design is unique.

The Clock’s Ticking: Take These Five Next Steps for Compliance

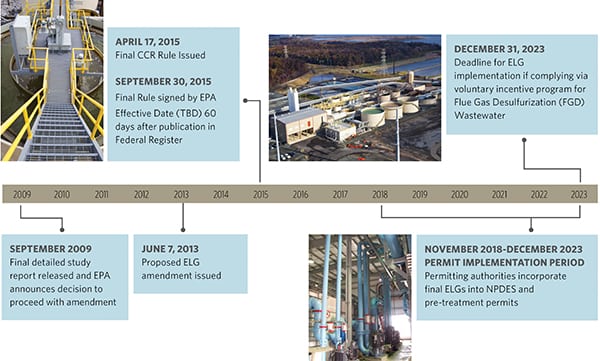

Starting now, plants have a minimum of three years to meet the new rules—and a lot to accomplish in that time. The EPA requires that all plants come into compliance with the new rule within the time period of November 1, 2018, through December 31, 2023 (Figure 1).

|

|

1. Timeline. The rule was published Nov. 3 and is effective Jan. 4, 2016. Courtesy: HDR Inc. |

Existing sources that are direct dischargers are required to meet best available technology (BAT) economically achievable limits. These new limitations apply on the date that a permit is issued to a discharger, following the effective date of the new rule, but no later than December 31, 2023. The rule does not build in any implementation period for meeting these limitations.

Pretreatment standards for indirect dischargers are self-implementing, meaning that they apply directly, without the need for a permit. In the new rule, pretreatment standards for existing sources (PSES) must be met by November 1, 2018.

The requirements for new source direct and indirect discharges provide no extended implementation period. New source performance standards (NSPS) apply when any NPDES permit is issued to a new source direct discharger, following the effective date of this rule. Pretreatment standards for new sources (PSNS) apply to any new source discharging to a POTW, as of the effective date of the final rule.

The timeline for compliance will vary depending on whether a plant discharges to a surface water source or a POTW, and if it’s a direct discharger when the facility’s NPDES permit is scheduled for renewal. So over the next three years, your plant may have to make decisions, engineer a solution, and implement a design (see sidebar).

Homer City Generating Station’s SolutionAt Pennsylvania’s Homer City Generating Station, solid engineering and compliance with current/prospective Environmental Protection Agency rules came together to pioneer a cost-effective solution for the effluent guidelines’ new flue gas desulfurization (FGD) blowdown stream regulations. One of Homer City’s three units uses a wet scrubber with an FGD blowdown stream. Under the new guidelines, that unit would require a dedicated wastewater treatment or evaporation system. Instead of constructing a costly biological treatment system or dedicated evaporation system, Homer City will reuse water in new dry FGD scrubbing equipment on the station’s other two units. The new FGD systems are designed to completely evaporate the station’s wet FGD blowdown, meeting the new guidelines by eliminating all wastewater discharge and saving the installation of millions of dollars of new treatment equipment. |

Not sure how to get started? Here are five basic steps your plant should take now to meet the timeline for compliance.

1. Evaluate the Impact of All Regulations. Over the past few years, the EPA has issued additional regulations for CCR, Clean Water Act Section 316(b), and flue gas emissions. Though the EPA did make attempts to coordinate the implementation schedules of both the CCR and the ELG rules as promised, there are other regulations, both federal and local, that can weigh heavily into the decision-making process. A plant’s best bet is to ensure evaluations are done holistically by considering the impact of all regulations—water, solid waste, and air related—to ensure the most cost-effective and most practical solutions are put in place to meet the facility’s challenges.

2. Keep Your Plant’s Total Current Water/Wastewater Picture in View. To determine the best solutions for the future and evaluate how changes will affect your plant, you need to completely understand its current water and wastewater picture. If you haven’t already done so, update your plant water and mass balances, determine any data gaps, conduct sampling and monitoring as required to fill in the gaps, and develop a complete plant picture.

It’s crucial to consider low-load or transitional operating cases in addition to evaluating the plant at baseload operations. Also, assess your current wastewater treatment. Consider whether this equipment will meet the new required effluent limits as is, or with a few upgrades. Knowing where your plant stands will help you quantitatively evaluate reuse opportunities and the need for new treatment equipment solutions.

3. Weigh the Benefits of the Incentive Program. The incentive program comes with an extended compliance timeline for plants that voluntarily choose to treat their FGD wastewater with a vapor-compression evaporation system and accept stringent numerical discharge limitations on mercury, arsenic, selenium, and TDS. As part of the solution evaluation process, it may be worth considering the pros and cons, and calculating the capital and operating costs associated with this alternative. This particularly applies to plants that expect to have more stringent WQBELs on the EPA-regulated parameters (specifically mercury) or on other parameters (such as boron or chlorides) added to their NPDES permits to protect the receiving watershed.

4. Look into Reuse/Recycling Opportunities and Other Ways to Eliminate or Reduce Wastewater Streams. With the EPA’s revisions to the anti-circumvention provisions in the final version of the rule, more opportunities remain for plants to minimize the impact of the rule through internal recycling and reuse.

Before you begin engineering a wastewater treatment system, analyze your plant’s water and mass balance, and see if there are low-cost opportunities to reuse wastewater streams or minimize flow rates to reduce your treatment volumes. Looking at the water and mass balance as a whole is important—don’t narrow your focus to only the wastewater streams that fall under the new EPA regulations. At most coal-fired power plants, particularly ones that have been in operation for decades, there are multiple streams pumped or drained to different locations, leaving many opportunities for the plant to optimize operations and minimize its water/wastewater footprint. A creative design could save you a lot of money.

5. Lock in Your Plan of Attack. With some facilities only having three years to comply, review your NPDES permit renewal dates and establish a site-specific timeline and plan of attack. Now is the time to act.

Start off on the Right Foot

Three years may sound like plenty of time, but there’s a lot to get done, and each plant’s solution will be unique. Although it is likely that the rule will be challenged, there’s no guarantee that time extensions will be granted. An effective plan for compliance starts with plant and system assessment, detailed design, and procuring the right equipment. Then the plan gets put into action with equipment installation, commissioning, testing, and tuning. So know the ELG rule and figure out how it affects your plant, then look at your plant holistically to identify what your plant really needs—and don’t be afraid to get creative.

It’ll take the right team to get all the parts and pieces working together, a team that really understands power plant processes, wastewater treatment, and the regulatory environment. Get the right mix of engineers, equipment suppliers, and constructors by your side, and your plant can find a smart, economical solution that’ll set you up for compliance.

— Colleen Layman (colleen.layman@hdrinc.com) is vice president / water principal at HDR Inc. and president of the Society of Women Engineers.