Dissolved gas control in a nuclear power plant’s water system, including the primary make-up water storage tank and refueling water storage tank, can be essential to reduce radiation source term (defined as a release of radioactive material). Controlling dissolved gases can also help reduce the formation of unwanted radionuclides, such as 14C and oxides of 60Co, and alleviate Primary Water Stress Corrosion Cracking (PWSCC).

C nuclides are produced by neutron-induced reactions on isotopes of carbon, nitrogen and oxygen molecules. Since these elements are present in the fuel, cladding, coolant, moderator and structural materials of nuclear reactors, removing the dissolved gases from the process water can reduce the formation of 14C nuclides.

60Co and 58Co nuclides are generated by a neutron reaction with steel alloy components within the reactor. 60Co oxide is formed when 60Co is exposed to the dissolved oxygen in the reactor water. Reducing the concentration of dissolved oxygen in the reactor coolant system (water cooling system) can aid in reducing the production of these corrosion products in the reactor.

CRUD (Corrosion Related Unidentified Deposit), such as 60/58CoNiFe2O3, is known to be a primary cause of radiation build-up in nuclear power plants. This type of corrosion product should be removed in order to reduce employee exposure during plant overhaul and decommissioning. Reducing the concentration of dissolved oxygen in the reactor make-up water storage tank (RMWST) and refueling water tank (RWT) can reduce the production of these radioactive corrosion products.

During normal operating conditions nuclear power plants produce various nuclides. Although nuclear plants are designed to contain and minimize the release of gaseous radionuclides into the environment, small quantities do escape the systems. Some nuclides are typically discharged in gaseous effluents. A small amount of 14C is released through normal effluent gaseous discharge paths such as plant vent stacks with 14CO2and 14CH4 chemical forms. Due to the long half-life (5730 years) of 14C nuclides, the isotope remains in the environment for a long time and is assimilated into the cells of plants and animals.

Recently, several nuclear power plants have installed Liqui-Cel® Membrane Contactors into their water systems to remove dissolved gases to help reduce the formation of radionuclides. This can protect operator and the environment. Liqui-Cel® degassing membrane systems are compact and can be installed virtually anywhere inside the plant due to their small footprint and flexible system design.

Liqui-Cel® Membrane Contactor Technology

Liqui-Cel Membrane Contactors use a microporous hollow fiber membrane to remove gases from or add gases to liquids. Gas flows across one side of the membrane and liquid is on the other side. Because the membrane is hydrophobic only the gases can pass through the pores. Applying a vacuum or using an inert sweep gas will lower the partial pressure of the gas and allow the dissolved gases in the liquid to easily transfer through pores in the membrane wall of the hollow fiber. The excess gases are then carried away into the vacuum.

Degasification Opportunities in a Nuclear Power Plant

Reactor Make-up Water Storage Tank

The Reactor Make-up Water Storage Tank (RMWST) typically uses a bladder or floating disk to prevent ambient air from entering the tank. Some plants use a nitrogen bubbling process to extract the dissolved oxygen from this tank. These technologies may not adequately prevent air from entering the tank and may increase the dissolved nitrogen level in the water. This make-up water is fed back into the Reactor Coolant System (RCS) to control the reactivity. Dissolved nitrogen and oxygen in the primary make-up water can increase the formation of 14C and CRUD.

Membrane contactors efficiently remove and reduce the amount of dissolved oxygen and nitrogen in the primary make-up water system. Water can either be re-circulated back through the membrane contactor system and into the RMWST or water can make a single pass through the degassing system and then back into the RCS.

Boric Acid Recovery System

Boric acid is used to control reactor power in a Pressurized Water Reactor (PWR) plant. During the boration and dilution process, a large volume of diluted water is stored in a hold-up tank. Most nuclear power plants use a boric acid evaporator for the recovery of boron. When a power plant operates a boric acid recovery system, water from the boric acid recovery condenser is pumped back to the RMWST. This condensed water contains slightly elevated concentrations of dissolved oxygen and nitrogen that can lead to the formation of 14C and corrosion products. To help alleviate this issue, Liqui-Cel Membrane Contactors are installed to reduce the amount of dissolved oxygen and nitrogen in the condensed water.

End Shield Cooling System

The purpose of the end shielding system in a CANDU (CANada Deuterium Uranium) reactor is to protect workers from radiation exposure during fuel on-loading. The end shield cooling system consists of a wall of steel balls encased in a concrete structure. The steel balls are in place to prevent radiation from passing through the wall. In order to remove the heat generated when the balls are exposed to radiation, they are cooled with water. If the oxygen levels exceed the limit value, the system’s material integrity can deteriorate and oxidation of the steel balls may occur.

Membrane contactors can also reduce dissolved oxygen in the cooling water. This is accomplished by continuously re-circulating the end shield cooling water through a membrane contactor degassing system.

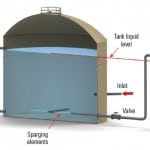

Refueling Water Tank (RWT)

A refueling water tank is not typically equipped with a rubber membrane bladder or floating disk. This can lead to high levels of dissolved oxygen and nitrogen in the water. Many nuclear power plants experience a rapid build-up of 60CoO and 58CoO radiation due to the high levels of dissolved oxygen flowing into the reactor during refueling and normal operation. High levels of oxygen and nitrogen may also produce elevated 14C activity.

Membrane contactors help protect against CoO spiking in the reactor coolant system by continuously re-circulating the refueling water through the degassing system.

Acknowledgments:

This information was compiled with the help of Kang Duk Won, Ph. D. He has tested, designed, and commissioned several membrane contactor systems in Korean nuclear power plants. Dr Kang has over 34 years of experience in the nuclear power industry. Nine of those years were with the Kori Nuclear Power plant and 25 years were with KEPCO Research Center. Currently, he is Director of Radiation Engineering Center for Hankook Jungsoo Industries Co., Ltd., a consulting firm for the nuclear power industry.

For more information visit Liqui-Cel.com