Artificial intelligence (AI) is evolving, and so is the demand for the infrastructure behind it. However, for those looking to build a sustainably conscious system, this growth raises a crucial question: What does an energy-efficient data center system look like?

While rightfully, much of the attention has focused on controlling energy usage of bigger systems as AI rapidly scales, it is equally important not to forget about the energy usage from the maintenance of these growing systems, particularly in terms of cooling.

COMMENTARY

Cooling plays a critical role in managing the rising heat from high-performance chips and dense rack configurations. According to the U.S. Department of Energy, cooling alone can account for up to 40% of a data center’s electricity use. In the context of AI’s expanding footprint, this makes cooling a key opportunity for sustainability gains.

The Shift to Liquid Cooling

Traditionally, data centers relied on air cooling, a method that pushes chilled air through raised floor systems to manage heat, but as thermal demands rise, air cooling often falls short. A growing number of facilities are now turning to liquid cooling systems, which are significantly more energy-efficient.

From chilled water loops, direct-to-chip cooling, and immersion systems, operators are increasingly deploying these methods to transfer heat more effectively, reduce equipment size, and support higher computing densities. This ultimately leads to an increase in computing power without expanding the physical footprint and is reflected in the market as analysts expect liquid cooling to grow from $2.84 billion in 2025 to more than $21 billion by 2032.

POWER is at the forefront of coverage for data centers, particularly related to how technology companies will source the power needed to operate their artificial intelligence ventures. Read our POWER Primer, “Focus on Data Centers,” and register today to attend our inaugural Data Center POWER eXchange event, scheduled Oct. 28 in Denver, Colorado

“Liquid-cooled data centers enable up to 50% more compute with higher core densities (480,000 cores versus 320,000) using the same or even less IT power than air-cooled systems,” explains David Gyulnazaryan, director and principal consultant at Impleon. “This shift increases allowable water temperatures (from 16°C to as high as 44°C), which can reduce cooling system power from 1,8 MW to 1,6 MW or even to 0,2 MW with immersion as well as reduce the overall power infrastructure.” In some cases, data centers have lowered cooling power consumption from 5.5 MW to just 3.8 MW.

Energy Infrastructure and Operational Gains

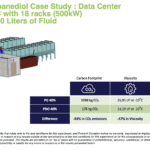

For those overseeing data center operations, improved cooling system infrastructure is critical for reduced energy usage and lower long-term costs. Operators can support meaningful energy infrastructure and operational cost reductions, particularly through capital expenditure (CAPEX) optimization from the usage of bio-based propanediol as an alternative to propylene glycol. The two main areas where these efficiencies can be realized are:

Reduced Electrical Infrastructure Requirements: During the design, retrofitting, or expansion of a liquid cooling system, fluids with lower viscosity at low temperatures, like Susterra propanediol, can enable the use of smaller pumps. This reduces the mechanical effort needed to circulate the coolant efficiently, which in turn allows for downsized electrical infrastructure and lowers upfront CAPEX.

Lower Pump Energy Consumption: Smaller pumps reduce infrastructure needs while also decreasing the system’s ongoing energy consumption. Since less power is required to circulate lower-viscosity fluids, the long-term operational expenses can be reduced.

With the right system design, fluids like Susterra can support more efficient cooling while offering both energy and cost advantages that can all be reflected in the data center’s ESG reporting.

Rethinking Fluid Type for Long-Term Performance

Operators should also turn to bio-based heat transfer fluids derived from renewable sources opposed to petroleum-based fluids, to maximize the liquid cooling benefits. Bio-based fluids can match or exceed the performance of fossil-based glycols while contributing less to overall energy consumption and emissions.

Susterra propanediol, for example, is a renewable glycol used in glycol-water blends for liquid cooling configurations, including direct-to-chip systems and facility loops. Although not an immersion fluid, it is effective for cooling immersion tanks externally. Its chemical stability at elevated temperatures helps minimize the formation of degradation by-products like glycolates and reduces nitrite depletion due to oxidation. These properties can improve fluid longevity and thermal consistency, making systems more energy-efficient over time..

As we scale to meet demand, we have a responsibility to build smarter. Whether it’s in hardware design or the fluids that keep systems running, thoughtful decisions will shape the future of a greener, more resilient digital world.

—Jessica Gallagher is Susterra Marketing Manager, Americas, at Primient Covation.

- DHS

- DOT

- Maxar

- x-energy

- fission surface power

- Boeing

- Drone Regulations

- unmanned aircraft systems

- Utility Drone Inspections

- DOE

- Lunar Nuclear Power

- FAA

- BWXT

- Sean Duffy

- Drones

- NASA

- Commercial Drone Alliance

- Southern Company

- BVLOS

- SwissDrones

- Westinghouse

- Lockheed Martin

- Phoenix Air Unmanned

- TSA

- Creare

- Aerojet Rocketdyne

- Intuitive Machines