In a significant technical triumph, GE has completed first installation of a new gas-fired power plant technology that it says can reduce nitrogen oxide (NOx) emissions to 5 parts per million (ppm).

GE on April 11 completed combustion upgrades on nine GE 9E gas turbines at five power generation enterprises in Shenzen, a major industrial city in Guangdong Province, China, outfitting them with the company’s newest iteration of its dry low NOx (DLN) solution—DLN1.0+ with Ultra Low NOx.

The turbines are owned by Shenzhen Nanshan Power Corp., Shenzhen New Power Corp., Shenzhen Datang Baochang Gas Power Generation Co. Ltd., Shenzhen Yuhu Power Co. Ltd., and CNOOC Shenzhen Power Co. Ltd.

The upgrade reportedly reduces NOx emissions from the E-class Chinese turbines from 50mg/m3 (about 25 ppm) to 15mg/m3 (about 7.5 ppm). According to GE, the reductions are achieved through an increase of the flame temperature. “A flame with a lower temperature will produce less NOx, and the key is to be able to mix air and fuel together prior to burning,” it explained. The DLN1.0+ with Ultra Low NOx configuration also offers more robust materials—including improved thermal barrier coatings—and new combustion hardware, such as a fuel nozzle, a liner and transition piece, which improve how the air is mixed with fuel. Both enhance the hot gas temperature profile, it said.

But GE’s upgrades also feature digital technologies, including a combustion dynamics monitoring system and improved controls system using “Corrected Parameter Control (CPC)”, which is “an advanced controls feature using real time information, such as ambient humidity, ambient temperature, inlet and exhaust pressure losses to adjust the fuel splits between the primary and secondary fuel circuit, and maintain the emissions below the target,” it noted.

Another Technology Milestone for GE

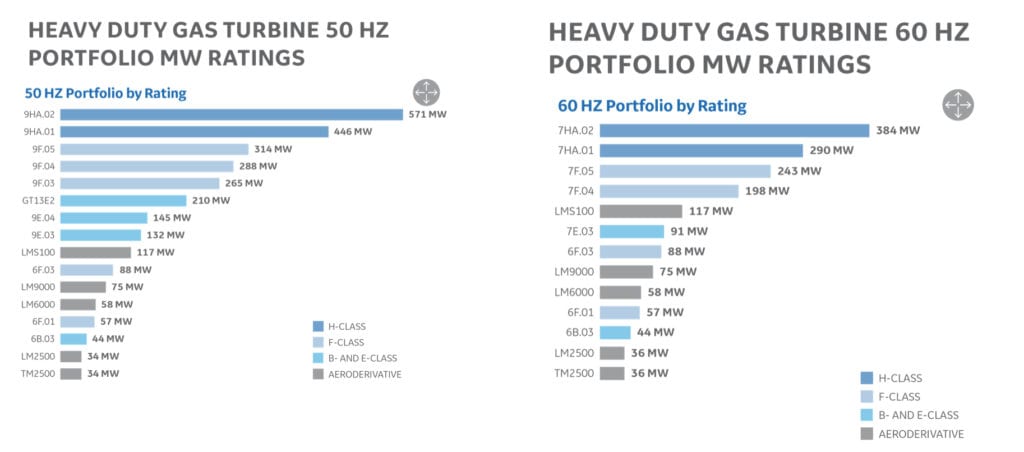

GE has been exploring refinements to its DLN combustion technology for decades before it was first commercially introduced for natural gas-fired heavy duty gas turbines in 1991. Research efforts starting in the 1970s yielded the DLN-1 solution for E-class turbines, and the DLN-2 solution for F-class turbines; the latter has also been applied to EC and H-class machines. In 2015, GE introduced a DLN2.6+ combustion system for new and existing 7F gas turbines, and in May 2018, it announced a “flex” upgrade solution, which combines the DLN 2.6+ combustor with axial fuel staging technology.

The DLN1.0+ with Ultra Low NOx solution stems from 43 million hours of operating experience for its B-class and E-class fleet, GE said last week. “It marks a big potential not only for the nearly 700 GE 9E turbines but also for approximately 1,000 GE 6B gas turbines operating around the world that combined can generate around 120 GW, which is roughly equivalent to powering the entire grid of Italy,” it said.

The upgrades in China will make the units more flexible because they are designed to accept fuels with larger Wobbe index fluctuations—a common indicator of fuel gas interchangeability in gas turbines. GE said that the solution could also potentially extend combustion system maintenance intervals to 32,000 hours or 1,300 starts and stops—or about four consecutive years of operation.

For the Shenzen plant owners, the technology offers a crucial new way to improve their emissions profile under the Shenzhen Municipal Government’s “Blue Sky” initiative. The initiative requires gas-fired power plants in the city to lower their emissions below 15mg/m³ within six months. Power plants that fail to comply with these requirements will be taken offline.

“Power generation companies are currently facing dual pressure from environmental indicators and economic performance,” said Liang Jianqiang, Head of Shenzhen Nanshan Power Plant in a press release. “We continue to search for a two-way solution to help contribute to local blue skies while improving asset performance.”

A Noteworthy Order to Tamp Down Coal-Fired NOx in India

On April 10, meanwhile, GE said it won a $20 million contract from India’s largest thermal generator NTPC for the supply and installation of low NOx combustion systems at 10 GW of thermal power plant capacity. The order is significant because while India’s government has notified industry it must comply with stringent new NOx limits, few established control technologies are suited to India’s high-ash coals. The new rules require coal plants built before 2004 to emit less than 600 mg/m3 of NOx. Plants installed after 2003 and before 2017 must emit no more than 300 mg/m3, and plants installed after January 1, 2017, must limit NOx emissions to 100 mg/m3.

NTPC is reportedly currently is carrying out eight pilot projects for installation of SCR and selective non-catalyst reduction (SNCR). Results for these projects are expected in 2019.

NTPC plants selected for installation of GE’s low NOx combustion systems are: Stage-I (2 x 500 MW), Mouda Super Thermal Power Station(STPS); Stage-I (3 x 660 MW) & Stage-II (2X500 MW) Sipat STPS; Stage-III (2 x 500 MW); Stage-IV (2 x 500 MW) & Stage-V (1 x 500 MW), Vindhyachal STPS; Stage-II (2 x 500 MW) Simhadri STPS; (3 x 500 MW) Vallur TPS; Stage-III (2 x 500 MW), Talcher STPS. The low NOx combustion system will be phased in over a period of over 30 months.

GE says if its technology is applied across India’s base, it could cut the country’s NOx emissions in half. The 10-GW project involves an in-combustion system modification of the boiler by staging the combustion air in the furnace to reduce the generation of fuel and thermal NOx during the combustion process. “The combustion modification technology can help reduce 30-40% of NOx emissions from these coal-fired boilers up to a level of less than 400 mg/m3 at 6% oxygen (O2) content in flue gas on dry gas basis at Induced Draft (ID) Fan outlet,” GE said.

“With more than 150-GW of coal-fired plants operating at sub-critical level, India is the world’s second largest NOx emitter, contributing close to 30% of annual NOx emissions of the country’s industrial sector,” said Lalit Sankrani, Clean Combustion Leader at GE South Asia in a statement.

GE noted it was selected in September 2018 by NTPC and Tata Chemicals to upgrade two coal-fired boilers in India with low NOx firing system. Those projects include NTPC’s 2 x 490 MW thermal plant in Dadri, Uttar Pradesh, and the 2 x 136 MW TPH Boiler Tata Chemicals Ltd in Mithapur, Gujarat—which was “the first standalone order for low NOx firing system upgrade in any coal-fired utility and industrial boilers respectively in India,” GE said.

—Sonal Patel is a POWER associate editor (@sonalcpatel, @POWERmagazine).