First ground has been broken on a 10-MW pilot of a novel supercritical carbon dioxide (sCO2) technology, a $119 million project that will refine the sCO2 power cycle and demonstrate component performance and scalability.

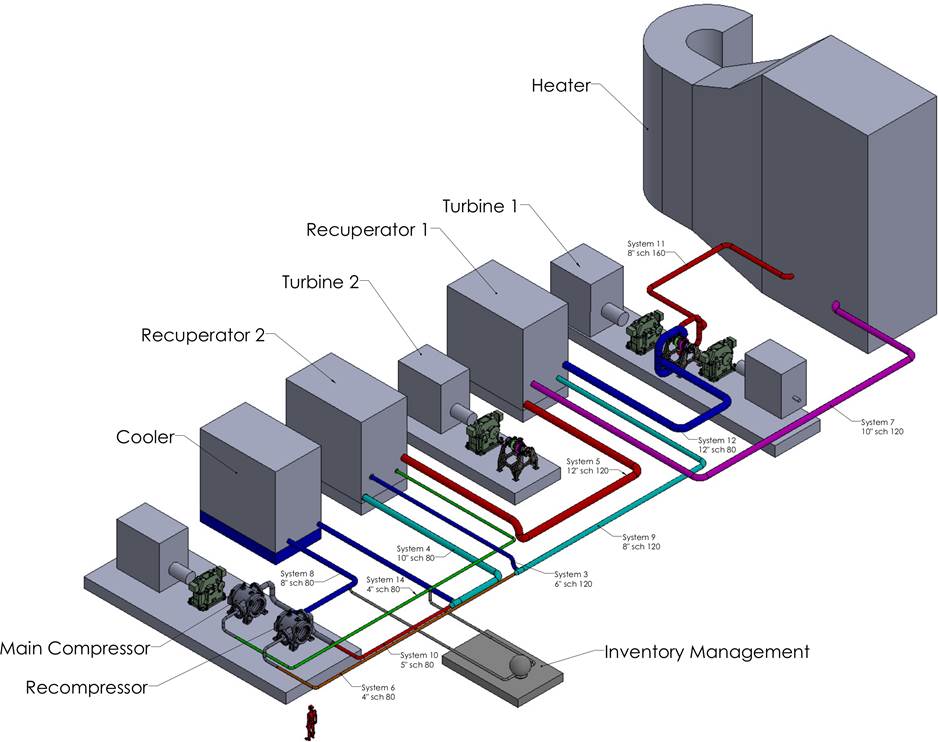

Construction of the Supercritical Transformational Electric Power (STEP) pilot plant at the 15-acre facility at Southwest Research Institute’s (SwRI’s) San Antonio, Texas, campus, kicked off on October 15, and it is slated to wrap up in 2020. The project is a collaborative effort between SwRI, the Gas Technology Institute (GTI), GE Global Research (GE), and the U.S. Department of Energy (DOE), and its National Energy Technology Laboratory (NETL).

Big Promise in a Small Package

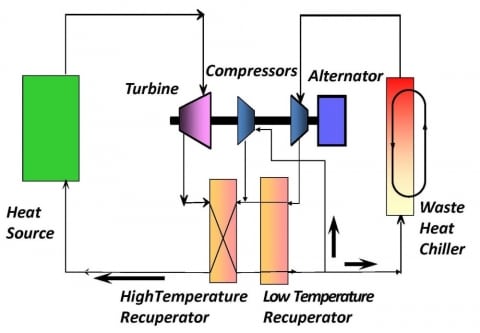

Supercritical CO2 cycles, which have a range of applications, including waste heat recovery, concentrating solar power, nuclear, and fossil energy, offer higher thermal efficiencies and power density than conventional steam Rankine and Air Brayton cycles in use today for power generation. But to realize these potentially game-changing cycles, common challenges associated with turbomachinery must be overcome.

The STEP project will use an sCO2 Brayton power cycle, which operates in a manner similar to other turbine cycles, but their high-power-density turbomachinery uses sCO2 as the working fluid.

“sCO2 is carbon dioxide held above a critical temperature and pressure, which causes it to act like a gas while having the density of a liquid,” SwRI explained. “It’s also nontoxic and nonflammable, and its supercritical state makes sCO2 a highly efficient fluid to generate power because small changes in temperature or pressure cause significant shifts in its density. Current power plants use water as a thermal medium in power cycles. Replacing it with sCO2 increases efficiency by as much as 10 percent.”

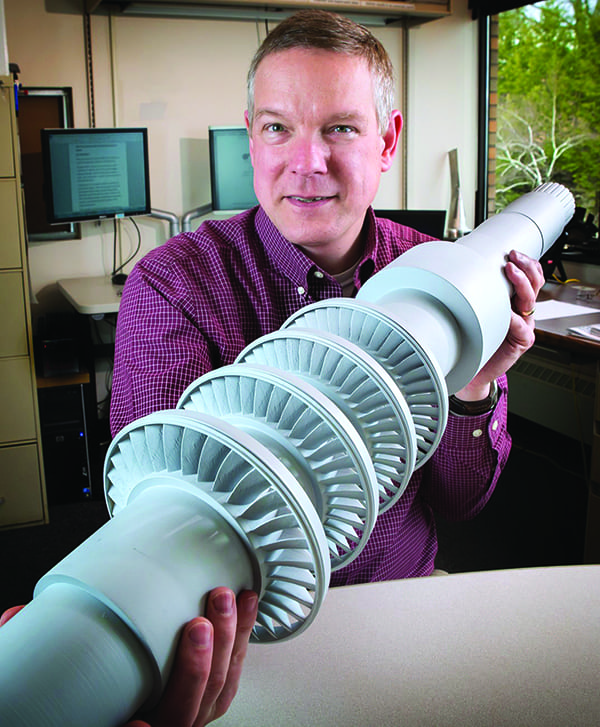

Among STEP’s most remarkable promises is that, owing to the efficiency of sCO2 as a thermal medium, its turbomachinery can be one tenth the size of conventional power plant components. The new STEP facility will be tiny: “a desk-sized sCO2 turbine could power 10,000 homes,” the research organization said. The potential compression of facility size offers several benefits, such as shrinking both the environmental footprint as well as slashing construction costs.

Key Project Objectives

When the facility is operational, researchers will work refine the sCO2 power cycle, demonstrate the machinery’s scalability, and its performance ability.

The project stems from a successful effort to design, build, and test a 1-MWe test loop—which consists of a 1-MWe turbine (with a 10-MWe frame size), a novel air-to-CO2 heat exchanger (made of Iconel 740H), and a commercial dense-phase pump. That effort involved testing a 5-MWt printed circuit recuperator sourced from Vacuum Process Engineering, and a 2.5-MWt air-to-CO2 primary heater with an inlet temperature of 470C and outlet, 715C.

As Jeffery Moore, SwRI institute engineer told attendees at the Turbomachinery & Pump Symposia on September 18, one of organization’s project’s key objectives will be to develop a megawatt-scale, high-efficiency sCO2 hot-gas turbo-expander that “advances state-of-the-art from a current [technology readiness level (TRL)] 3 to TRL 6.”

The project team will also work to optimize recuperator technology for sCO2 applications to slash manufacturing costs. A third key objective is to close two critical technology gaps for concentrating solar power (CSP) sCO2 plants by boosting efficiency and paring down the levelized cost of electricity.

Key achievements have already been achieved for the turbine, Moore noted. The turbine, which has the “largest-scale, highest temperature sCO2 expander developed to date,” also uses industrial bearings and seals, which can be scaled to utility-scale; a one-piece rotor manufacturing developed to eliminate the blade-to-rotor attachment. Researchers have also overcome casting issues, and developed a rotordynamic design to accomodate high density gas and high speed.

SwRI noted the pilot demonstration is specifically “designed to evolve over time to keep pace with industry advancements.” It features skid-mounted components that provide flexibility and a reconfigurable design.

So far, the DOE has contributed nearly $80 million to the STEP project, and it remains one of a few state-led efforts to develop sCO2 cycles. Others include South Korea, which is exploring a sCO2 Brayton cycle for a small modular reactor, and China has funded research into a cascaded sCO2 system integrated with solar and biomass.

—Sonal Patel is a POWER associate editor (@sonalcpatel, @POWERmagazine)

Corrected (10/19), to reflect that the team has already commissioned a 1-MWe test loop