Partner Content

-

Partner Content

MPW Mobile Ultrafiltration and Demineralization Units Exceed Canadian Power Plant Expectations

Challenge:

After a major refurbishment, a Canadian nuclear plant required additional process and boiler feed water for plant start-up and commissioning.

The plant’s raw water supply contained measurements ranging from 1-10 NTU, conductivity from 70-100 and color units ranging from 180-420. The plant also experienced highly variable flow rates, ranging from 0-600 GPM, and issues with the -

Partner Content

MPW’s technology leads to superior cleaning at Ohio plant

Challenge

A global polymer producer located in Ohio sought to improve the annual outage cleaning of its heat exchangers.

Historically, industrial cleaning contractors hand lanced the heat exchanger tubes, servicing four to six exchangers per night for two weeks to fit within the outage schedule. But often, multiple heat exchangers would require re-cleaning to allow for heat -

Partner Content

The Cloud Advantage

The Cloud Advantage

6 Reasons Power Leaders are Moving to Cloud

Gaining business value from massive volumes of asset sensor datarequires a unique operating environment not typically part of the power infrastructure. What must power leaders consider when taking steps to transform their operations with data and analytics?

Discover the power of digital in the cloud in -

Partner Content

MPW’s Automated Bundle Blaster

MPW’s Bundle Blaster Side Cleaner system is designed to remotely clean the shell side of small to medium

sized tube bundles, up to 36 feet in length. The tube bundle is placed on hydraulically actuated rollers to

incrementally turn the bundle during the cleaning process while the cleaning head runs horizontally on a track

over the bundle. MPW’s -

Partner Content

Powering The Future

Discover the Power of Digital

White Paper: Powering the Future

Leading the Digital Transformation of the Power Industry

By:

Marco Annunziata, GE’s Chief Economist

Ganesh Bell, Chief Digital Officer of GE Power

Digital technologies are transforming the power sector. From delivering power to underserved markets to managing variations in market conditions and fuel costs, power leaders are using analytics and -

Partner Content

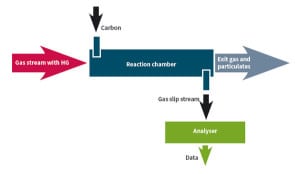

Improve Your Mercury Compliance Testing

US power generators and cement plants are now under pressure due to recent legislation. Many plants are now scrambling to tighten up their mercury control procedures. Luckily, ADA Carbon Solutions’ Dynamic Mercury Index test has been developed to ensure consistent quality of sorbents used in activated carbon injection.

-

Partner Content

MPW’s Improvements Lead to Savings for Southeastern Pulp and Paper Facility

Problem

A Florida pulp and paper mill faced a complicated, dangerous process to clean its power boiler during scheduled outages.

Previous efforts to clean the boiler included manual water blasting from scaffolding, which posed a safety risk to workers below due to the potential for falling debris.

Solution

The Operations team at MPW Industrial Services recommended that the facility’s -

Partner Content

Free eBook: 7 Ways to Achieve Operations Reliability

Learn how power leaders are leveraging Asset Performance Management (APM) to drive less unplanned downtime, safer operations and a competitive edge.

-

Partner Content

Case Study: MPW’s Automation Simplifies RO Replacement Process for Indiana Energy Plant

Case Study: MPW’s Automation Simplifies RO Replacement Process for Indiana Energy Plant