Finnish company Wärtsilä evolved from humble beginnings as a sawmill into a global marine and energy powerhouse that is today a model of customer value creation, decarbonization, and growth amid uncertainty. Driving that triumph over its 188-year history is a consistent spirit of innovation and flexibility.

POWER

In 2021, Wärtsilä once again assessed its future direction. Throughout its 188-year history, the Helsinki, Finland–headquartered technology and lifecycles solutions provider for the marine and energy markets had experienced twists and turns, waves of soaring growth that were sometimes allayed by turbulence from faltering markets. The task facing Wärtsilä executives in 2021, however, entailed first finding the company’s bearing amid the fog of uncertain pandemic-released recovery and accelerated pressure on environmental performance. Then, the company would need to navigate toward a target position that would provide consistent value, all while keeping its massive workforce—a diverse team of 17,000 energy and maritime professionals in more than 200 locations across 68 countries—safe and on board.

Executives worked out the answer in a crucial strategy they called “The Wärtsilä Way.” The strategy is based on two themes—transformation and performance—that leverage the skillsets and technology expertise accumulated by the company over its long history to address current and emerging market needs.

“The Transform theme refers to decarbonization, creating new business opportunities by leveraging growth in electricity generation, balancing power, and green marine transport,” explained Wärtsilä President and CEO Håkan Agnevall in the company’s 2021 annual report. That theme will be crucial to the company’s October 2021 unveiled goal to become carbon neutral in its operations and provide a product portfolio ready for zero carbon fuels by 2030.

Courtesy: Wärtsilä

“The Perform theme centers around leveraging market recovery and growth, supported by robust execution, continuous improvement, and the company’s commitment to both financial and sustainability targets,” Agnevall said. The company’s underlying purpose will also be vital to the strategy. “Wärtsilä’s purpose to enable sustainable societies through innovation in technology and services is well connected to the Transform and Perform themes,” he added. The company will also prioritize five key attributes to achieve that purpose: emphasized customer value, high-performing teams, decarbonization, service growth, and continuous improvement. All of these attributes will help the company achieve a revised financial target of 5% organic growth annually and reach a 12% operating margin, Agnevall said.

The Technology Evolution of Wärtsilä’s Diesel Engines Understanding the pivotal role diesel engines would play in propelling ships, Wärtsilä first set out to design its own diesel engines in 1954, contracting Wilmer Wahlstedt (Figure 2), a young civil engineer, to lead the design work at a Wärtsilä shipyard in Vaasa (or Vasa), a city on the west coast of Finland. The company’s first engine unveiled in June 1959, dubbed the Wärtsilä Vasa 14, had only three cylinders. The pilot engine was soon followed by a six-cylinder engine. The company’s most pivotal innovation in diesel engine design, however, came in the 1970s, with the launch of the Vasa 32. Later renamed the Wärtsilä 32, the engine grew into Wärtsilä’s highest-selling product globally, and it has been used in vessels ranging from fishing trawlers to cruise ships. A version of the Vasa 32 capable of combusting heavy fuel oil (HFO) likewise “revolutionized the world of fuels,” said Jussi Heikkinen, Director, Growth and Development, Americas, Wärtsilä Energy. “There were not such small engines in the world, but there was a lot of HFO in the world, and supplies were very stable and cheap,” he added. The Vasa 32 “suddenly opened [the fuel] to very large ship engines and power plants,” he said. The Vasa 32 remained integral for the company through the 1990s, even through a debilitating recession in Finland. Leveraging early advances in automation, the company launched the Wärtsilä 46 engine in 1985, and its first liquified natural gas engine in 1995. In the 2010s, Wärtsilä expanded the portfolio with the low-speed Wärtsilä X62 and the X72 engines. In 2013, the company launched new engines based on low-pressure technology, as well as two auxiliary engines. And a year later, it introduced the 46DF engine, solidifying its leadership in dual-fuel technology. However, Wärtsilä says the most significant technological progress came in 2015, with the launch of the Wärtsilä 31, an automotive-derived engine that can run on various HFOs, as well as gas and diesel. The Guinness Book of World Records recognized the engine as the world’s most efficient four-stroke diesel engine at that time. |

A History of Resilience

All of this would seem lofty if it were not for Wärtsilä’s record of reinventing itself time and time again. The company’s long history of innovation—as well as flexibility in the face of industrial and social transformation—are foundational attributes that have kept it thriving beyond its many transformations, and even propelled it into new markets.

The company’s history began in 1834 when Wärtsilä was established when the governor of Karelia county, then a part of Eastern Finland, approved the construction of a sawmill by a river in Tohmajärvi municipality (Figure 1). By 1898, the mill had grown into a larger company that included ironworks. The company had expanded significantly by the 1930s owing to several key acquisitions, including a machine and bridge construction firm, two shipyards, and a paper mill, and it moved its headquarters to Helsinki.

Wärtsilä says it marked its foray into the diesel engine era in 1938 as it entered into a license agreement with German shipbuilder Friedrich Krupp Germania Werft AG. While engines were first delivered under that agreement in 1940, and others with Nohab and Sulzer in the early 1950s, the company did not set out to design its own diesel engines until 1954 (see sidebar “The Technology Evolution of Wärtsilä’s Diesel Engines”).

According to Jussi Heikkinen, a 40-year Wärtsilä veteran who today serves as Wärtsilä Energy’s Director of Growth and Development for the Americas, Wärtsilä took a concerted leap from marine engines and established a power plant business in 1986. Following a pioneering installation in Tanzania “the business started to grow in a systematic manner,” first through demand from India and then from independent power producers (IPPs) in the U.S., which proliferated in the 1990s as deregulation gained steam. These companies bought “huge power plants of up to 150 MW, some of them were floating,” Heikkinen noted. Wärtsilä moved into building them as engineering, procurement, and construction (EPC) contractors via a power plant services business that remains lucrative today.

Wärtsilä says that the power plant business in the following decades continued to thrive, despite a volatile phase in its corporate history. In 1989, Wärtsilä Marine, the company’s illustrious and long-standing shipyard company, went bankrupt. This pushed Wärtsilä to pool its marine resources with shipbuilder Valmet, resulting in an exchange of assets: Wärtsilä acquired Valmet’s shipbuilding activities, and Valmet took over Wärtsilä’s paper machines. In 1989, Wärtsilä also signed a merger agreement with the Scandinavian manufacturing powerhouse Lohja. After an extraordinary meeting, Lohja shareholders approved a new name for the company: Metra Oy Ab. In 2000, however, Metra shareholders readopted “Wärtsilä” as the company’s formal name.

The 1990s brought significant change for the energy business, too. The company went from “selling technology to profiling itself to a comprehensive solutions partner. Rather than simply building and selling facilities, Wärtsilä adopted an approach based on the customer’s long-term needs and goals as well as social and economic analyses based on them,” the company says. The attribute helped Wärtsilä “stand out from the competition” so distinctly through the 1990s that it propelled the company into an accelerated period of “internationalism.” The active development of businesses in new countries and markets was driven by strategic thinking to fill in gaps for needed technology. Wärtsilä power plants were deployed in the Caribbean, countries in Africa, Indonesia, and other developing economies, helping to spur new infrastructure and growth.

Meanwhile, as businesses became more maintenance-driven, Wärtsilä acquired engine suppliers and took over their global maintenance operations. By the early 2000s, the company had transformed into a “genuinely global company.” It had “the ability to find new market areas, both geographically, and in terms of products, as well as react quick to market changes and create new products and applications,” Wärtsilä says. That included several acquisitions, including of Finnish company Sermet Oy, a biopower company that specialized in small and medium-sized boiler plants running on biofuels, oil, and gas, in 2001. In 2008, it formed a joint venture with Metso combining Metso’s Heat & Power business and Wärtsilä’s Biopower business.

In the latter 2000s and early 2010s, Wärtsilä began to snap up a significant market share in the gas power business, leveraging a shift driven by cheaper, more prolific natural gas supplies. However, the market was shifting. Heikkinen recalls visiting a Colorado dispatch center, where a dispatcher demonstrated the value of balancing intermittent wind power. “I think that was a major culmination point, when the old market that we were totally dominating, [was poised] to gradually fade away,” Heikkinen said.

“There was a huge gas turbine market, but we knew they are still not a very good choice if you have to start and stop all the time because the sun is not shining and the wind is not blowing,” he said. To stay ahead, Wärtsilä immediately set out to find solutions to issues that could crop up as the world transitioned toward more flexible energy systems with a rapidly increasing share of renewable energy, a declining inflexible baseload generation, and a more comprehensive application of storage technology, he said.

Among the company’s significant acquisitions over the past 10 years have been its 2017 buy-out of Greensmith Energy Management Systems (GEMS), a U.S.-based provider of stand-alone energy storage and hybridized energy systems, control software, and integration expertise. The GEMS business unit has allowed Wärtsilä to rapidly expand its footprint in the energy storage market globally and position itself as a premier energy system integrator (Figure 3). Since 2010, Wärtsilä has also been focusing on becoming a world leader in balancing and power optimization. “That continues to clearly be our strategy today,” he said (see sidebar “Wärtsilä Today: A Comprehensive Technology and Solutions Partner”).

Thinking Ahead to Equip a Rapidly Changing Power Landscape

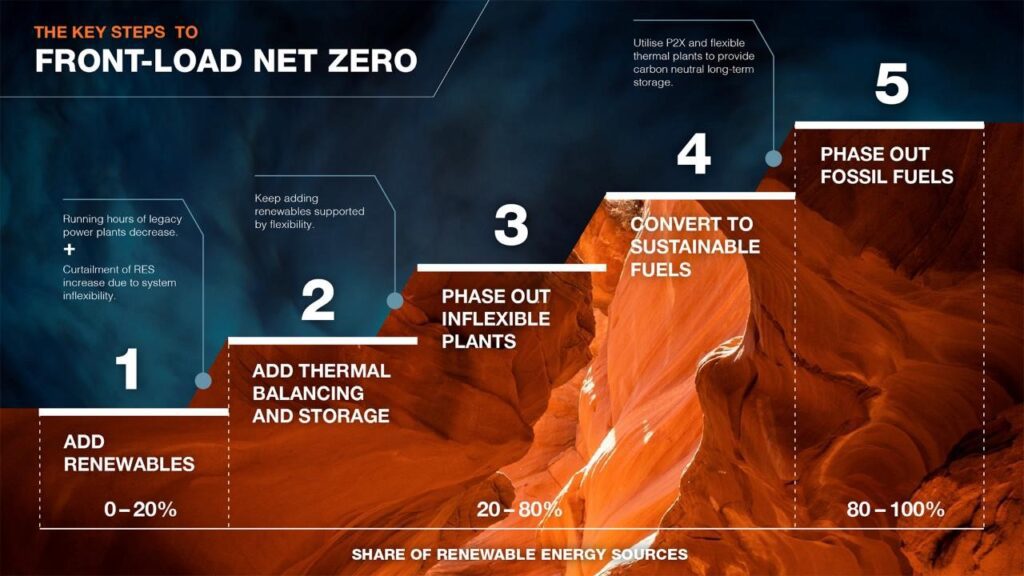

Wärtsilä has been aware that balancing will be an essential attribute for a sustainably decarbonized grid for as long as a decade. It got that insight from extensive system modeling using PLEXOS (by Energy Exemplar), an energy simulation software that it uses both in long-term capacity development optimization and short-term dispatch optimization. Balancing, Heikkinen explained, requires load and generation to always be in balance “otherwise the frequency starts to float away from 60 Hz or 50 Hz,” he said.

An ideal sustainable system “has enough renewables to produce all required electricity and also has enough storage capacity to deploy that electricity without interruptions,” he said. A final step would entail switching engine power plants to sustainable fuels, such as hydrogen. “Power systems and power plants would at this point be completely carbon neutral, and the use of fossil fuels would have ended. In this case, we would only be using wind and solar, while storing their energy in batteries,” he said. However, “When the system would be close to being drained, for example during the night, you would then start up the hydrogen power plants until the sun rises,” he added. “Batteries are a good short-term solution, but flexible power plants and sustainable fuels provide the best long-term solution today. There will still be fuel used in the future, but those fuels will be sustainable as well.”

For now, however, balancing renewables with energy storage in the form of batteries alone can require a massive build out if this is the only source of balancing power, he suggested. Despite big ambitions by policymakers, energy systems cannot currently handle a complete removal of fossil fuels entirely right now, he said.

The company suggests the most cost-effective solution using existing infrastructure is to use a flexible engine power plant—an internal combustion engine (ICE) power plant, like the Wärtsilä 34SG Balancer—along with energy storage systems (ESSs). “This combination provides the necessary firm capacity for the system, and what’s more important, can go online and off-line in just a matter of minutes,” Heikkinen said. “If the sun shines, you switch off the flexible grid balancing plants and use solar generation, which charges the batteries. When the sun doesn’t shine, and there are just calm winds, you first use power from the energy storage system, and when stored energy is exhausted, switch over to the flexible power plants. With this arrangement, the power plants are always used last, not first.

According to a recent Wärtsilä white paper, energy storage shows great potential in solving the issue of degrading frequency stability and is increasingly being utilized by system operators around the globe to tackle the inertia issue. “By providing fast frequency response (FFR), energy storage could compensate for the lack of system inertia and the reduced availability of spinning primary reserves, thereby securing the system against sudden imbalances,” the company explains.

The white paper describes a case study that used a combination of techno-economic portfolio optimization tools and dynamic grid simulations to study how energy storage and grid balancing power plants can allow grids with a high share of renewable energy to be operated with minimal restrictions to the generation mix. It concluded that the combination secured the system during low-inertia periods. “The results of the case study show that with support from ancillary energy storage and grid balancing engines the share of renewables in the test system could be increased from 33% to 58%, CO2 emissions could be cut by half, and total system costs could be reduced by 11% without endangering system frequency stability,” it says.

Wärtsilä Today: A Comprehensive Technology and Solutions Partner

Power products and services make up much of Wärtsilä’s businesses today. The company is split into four businesses (listed below in order of total net sales).

Wärtsilä Energy. Armed with an ambitious goal to lead the transition toward a 100% renewable energy future, the business helps customers achieve decarbonization by developing market-leading technologies. These cover future-fuel-enabled balancing power plants, energy storage, and optimization technology, including the GEMS Digital Energy Management Platform. “Wärtsilä Energy’s lifecycle services are designed to increase efficiency, promote reliability, and guarantee operational performance,” the company says. Wärtsilä Energy has nearly 5,000 dedicated employees and provides about 39% of total net sales.

Wärtsilä Marine Power. The portfolio includes engines, propulsion systems, hybrid technology, and integrated powertrain systems. Marine Power’s offering includes performance-based agreements, lifecycle solutions, and a global network of maritime expertise. The business has about 8,200 dedicated employees, and it also provides 39% of total net sales.

Wärtsilä Voyage. This business transforms how vessels perform their journeys and ports manage their operations by leveraging the latest digital technologies. Using data and artificial intelligence (AI)-driven software, the company delivers real-time insights into operations, performance, and energy use to enhance safety, efficiency, and reliability, saving fuel and minimizing emissions. Solutions combine bridge infrastructure, cloud data services, decision support systems, and intelligent port solutions to enable shore-to-shore visibility. Wärtsilä says the segment is committed to building an “end-to-end connected digital ecosystem for shipping where all vessels and ports are integrated, and all operations are safe and sustainable.” Wärtsilä Marine Systems. This business supports customers products and lifecycle services related to the gas value chain, exhaust treatment, shaft line, underwater repair, and electrical integrations.

Looking Ahead: Sustainable Fuels

|

While Wärtsilä has researched hydrogen as a fuel for 20 years, as part of its commitment to help its customers meet decarbonization goals and limit climate change, in May 2020, the company set out to develop a combustion process in its engines to achieve 100% hydrogen fuel combustion. The company expects to launch a power plant design for hydrogen blends in 2022, followed by a concept for pure hydrogen in 2025. Paramount to these efforts will be to add high-volume hydrogen capabilities to its engines, which are already significantly fuel-flexible. The company says the development is crucial to its strategy to “future-proof its engine technology in line with the global trend towards decarbonization of the energy and marine markets.” However, its engine power plant solutions of today are already “future-proof investments, since the same engines will run on carbon-neutral sustainable fuels, either with tuning alone or through conversions,” the company notes. “For the transition phase, which we see happening through natural gas, the cleanest fossil fuel, we have developed our engines to operate with up to 25 vol% hydrogen blends.” The company launched a major test program in July 2021 after carrying out full-scale engine tests at its engine laboratory in Vaasa, Finland, and |

testing facilities in Bermeo, Spain, to assess the optimum engine parameters for running engines fully on hydrogen. In March 2022, the company began operating two Wärtsilä 34SG engines, a combined output of 11.6 MW, that can run on a 3% hydrogen and natural gas blend (the hydrogen is blended before feeding the fuel mix into the engine) at Keppel Offshore and Marine’s “Floating Living Lab” in Singapore.

In addition to hydrogen, “other potential renewable fuels are being studied for future applications, and Wärtsilä engines are already capable of combusting 100% synthetic carbon-neutral methane and methanol,” it notes. In 2022, notably, the company released its Wärtsilä 32 Methanol engine to the market. In tandem, Wärtsilä has already proven an engine concept running on blends of up to 70% ammonia. It expects to have engine concepts ready for operating with pure ammonia fuel in 2023. A project backed by the Norwegian government for a “long-term, full-scale” test of ammonia as a fuel in a marine four-stroke combustion engine is also underway. Wärtsilä says the full-scale fuel testing program will be integral to paving the way for ammonia engines “to be used in real vessel operations within a few years.” Several shipowners “have shown interest in this possibility,” it notes. |

A Focus on Research and Development

Because Wärtsilä believes a broad array of solutions (Figure 4) will be needed to decarbonize the marine and energy sectors, the company has notably committed to investing a “stable” 3% of net sales in research and development (R&D). The company suggests that “different solutions will be used in different applications and in different geographies.” The company also projects a gradual shift to new technologies and blending of different types of fuel (see sidebar “Looking Ahead: Sustainable Fuels”). “Our focus in-house will remain on developing core technologies. Through partnering with technology providers, we are able to ensure a broad solution offering for our customers,” it says.

The R&D initiatives are broadly based on projections about emerging business opportunities decarbonization will create for both the marine and power sectors. As part of its “The Wärtsilä Way” strategy, Wärtsilä anticipates that decarbonization will fuel an “unprecedented” rate of change in new build and existing fleet. It said that regulations could also accelerate change in the demand for “green” transport.

In the power space, Wärtsilä forecasts that the amount of power generation will triple, and renewables will grow eight-fold by 2050. The most substantial growth may come in the balancing power market, which the company projects will increase tenfold.

“As a technology leader in the decarbonization transformation, Wärtsilä has significant value creation potential as a pioneer and leading partner for decarbonization,” the company says. While actively involved in utilizing sustainable fuel technologies, for both carbon neutral and zero-carbon fuels, such as biofuels, methanol, ammonia, and hydrogen blends, the company continues delivering technologies that maximize energy efficiency when using fossil fuels. In addition, Wärtsilä has a leading position in power system optimization of different generating assets, “where both energy storage technology and grid balancing power solutions play a key role.”