Weighing Costs and Benefits in Hydropower Maintenance and Upgrade Decisions

Choosing whether to maintain or upgrade hydropower plant components can be difficult. Poor original equipment reliability can force changes, but often a detailed cost-benefit analysis is needed to make decisions. Understanding how others have tackled the process can help ensure success at your plant.

Although other renewable sources of energy may be growing at a faster rate, more electricity continues to be generated in the U.S. by conventional hydropower than by wind, solar, and geothermal power combined. A market report released last year by the U.S. Department of Energy Wind and Waterpower Technologies Office noted that of the 2,198 active hydro plants in the U.S., most of the 79.64 GW of total installed capacity is located at large projects built between 1930 and 1970.

A lot has changed since those plants began generating power. Technology and design techniques have evolved, allowing vast improvements to all kinds of power plant equipment. Digital governing systems now offer plants programmable features, providing flexibility and making what used to be difficult changes simple. New runner designs and insulation improvements have enhanced efficiency and increased capacity. Composite bearings have made maintenance easier and less time consuming.

So the question many decision-makers must answer is: “Should we continue to maintain the old equipment in our relatively reliable facilities or should we upgrade to new equipment that captures the benefits offered by the latest technology?”

Evaluating the Risk

Making that type of decision may seem pretty straightforward, but Darin Johnson, president of Seattle-based BIS Consulting, told POWER that there is more to it than a person might think. Determining if a new piece of equipment that offers a 2% efficiency improvement is a cost-effective upgrade can require the use of heavy-duty dispatch models.

Another question that often arises is: “If a unit is being taken out of service for an extended period of time to complete one plant improvement, does it make economic sense to increase the scope and take care of other upgrades at the same time?”

That’s where a company like BIS Consulting can help; it has been involved in several hydropower assessments as part of life extension programs. The company basically applies a risk-based approach to estimate the benefits of replacing or refurbishing old components. It determines the likelihood of component failure, the consequences if a failure occurs, and then weighs the risk against the incremental capital costs to conclude whether an upgrade is justified.

“We’re sort of doing the calculations that everybody is thinking about,” Johnson said.

Most companies understand what the tradeoffs are, but actually performing the calculations explicitly and documenting all of the assumptions requires more than just understanding the variables. The experts who do that work typically use large databases, failure probabilities (which often follow bathtub curves where failure rates decrease, level out, and then increase as equipment ages), and then adjust the numbers based on operations and maintenance history. Every situation is unique, and many require a rigorous data-gathering process.

“All 47-year-old stator windings are not alike,” said Johnson. “Some have been abused or just had bad luck, and some are still in pretty good shape.”

Upgrade? Not So Fast!

Many people jump to the conclusion that if a unit is going to be offline for an extended period of time, they should do every possible upgrade or maintenance task that they can think of to take advantage of the opportunity. What many fail to take into account is that cash is valuable. If the benefits of the work are not realistically assessed and evaluated, a lot of money can be wasted.

“My working theory about why that happens is that, oftentimes, the decisions about what’s going to get done get made by engineers who face the downside of a failure,” Johnson said. “They look bad if things fail, but they don’t really look all that good if they save a little bit of money.”

For example, if a project has a $50 million budget and removing a job from the scope saves $500,000, the work group may get a pat on the back for being frugal. But, if the component later fails as a result of the decision, the person who made the final ruling could face heavy scrutiny.

“I think where we’ve been able to help is to get down on paper what would be the benefit of not doing something,” Johnson said. “So it’s really a communication tool as much as anything else.”

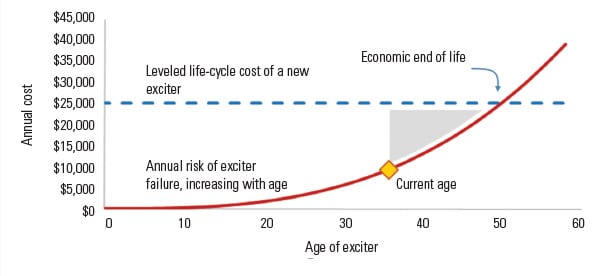

Aggregating information in a way that allows decision-makers to see, for example, that there is a 4.3% chance that something will fail next year, a 4.37% chance that it will fail the following year, and escalating percentages thereafter, is very valuable (Figure 1). The consequences of a failure, such as one month of lost energy production or collateral damage to other equipment, must also be factored into the equation.

Johnson offered one example from a project he was involved in at the Grand Coulee Dam (shown in the opening photo). His group was brought in to evaluate the step-up transformers (Figure 2) for a couple of the older powerhouses. There were 18 units total. He said the U.S. Bureau of Reclamation was really worried about them failing.

“Our estimate agreed with them,” Johnson said. “They actually were pretty likely to fail, but because there were so many of them, losing one really wasn’t such a catastrophic thing. The cost wasn’t really all that high. So, in our estimation, it was better at the time to keep multiple spares on hand and tolerate failure rather than spend a whole bunch of money replacing all of the equipment.”

Although the Bureau of Reclamation has since decided to move forward with a more extensive transformer replacement project at Grand Coulee, the decision to delay the work extended the total useful life of the equipment and saved money in the long run.

New Design Solves Gear Unit Problems

In some cases, repeated failure makes the decision to upgrade an easy one. That was the case for Düsseldorf, Germany–based Uniper. Its Hemsjo Nedre hydropower plant in southern Sweden had experienced multiple problems with an existing horizontal turbine gear unit.

The original single-stage gear unit was supplied in 1981 by ASEA—a legacy brand of Santasalo. It had been repaired several times by third-party gearbox service companies, but it continued to be plagued by high operating temperatures, and some cracks had formed on internal components. That was when Santasalo got involved.

“We went onsite and checked the installation,” said Henrik Cederberg, area sales manager for Santasalo. “We made a whole new calculation for this application.”

After assessing the situation, three options were proposed to resolve the problems. The first option was to repair the old ASEA UAAF 170 unit by installing new internal components, new bearings, and an upgraded lubrication system. The second option was to construct and install a new ASEA UAAF unit, built in accordance with the old design documentation. The third option was to create a completely new design. This option would allow a modern single-stage helical gear unit to be installed, including a new lubrication system and offline filter. Because it would be built with the same dimensions as the old ASEA unit, shaft positions, foundations, and couplings would remain unchanged. Uniper selected option three.

“A lot of things have changed since ASEA made the original unit for the client,” Cederberg said.

He noted that the profile of modern gears is better than it used to be. These days, gear teeth are more accurately designed for the expected or calculated load. Compensation grinding ensures full tooth contact and helps reduce noise. Materials are better understood, and the hardening process is more precise. Bearings have also improved, with new types and altered setups common in modern gear units.

“When you make a new gear unit, you have a lot of things that are better than before,” Cederberg said.

Engineering design technology may have come a long way from the old-school days of slide rules, but the need for good estimates of operational parameters during the design process hasn’t changed.

“When you perform the calculations for the gear unit, it is really important to have the correct information. We made all the calculations over again, using new information from the customer,” Cederberg added.

In the end, Santasalo delivered the custom-made unit within an 11-week window to fit Uniper’s schedule. But the proof of the pudding is in the eating. Since the new gear unit (Figure 3) was installed, operating temperatures and noise are substantially reduced, and oil testing shows no signs of trouble.

Seal Upgrade Allows Real-Time Condition Monitoring

Mechanical seal failure is another problem that can force maintenance to be performed sooner than expected. The technology used in most seals is not new, but in the past it has been hard to predict when wear components in the seal were approaching their end of life. Many companies rely on scheduled maintenance, based on operational runtimes, but this could mean tearing into a seal that is still in satisfactory condition, just because the calendar suggests that its time is up.

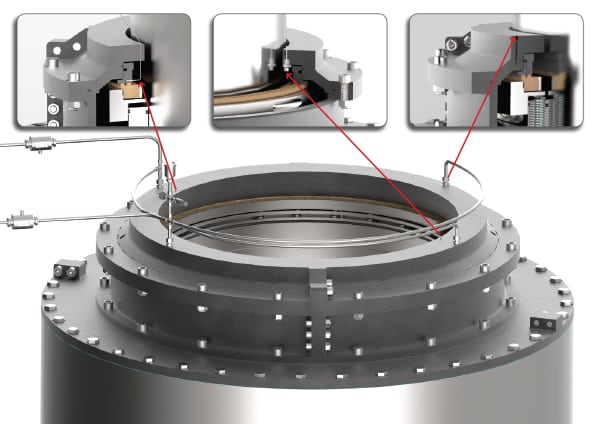

However, Finland-based Wärtsilä has come up with a new solution that may eliminate the guesswork. The company’s REguard water-lubricated face-type seal with integrated PIMS (pressurized interface management system) offers some unique features designed to allow real-time monitoring (Figure 4). The system will be used on two horizontal turbine runners in the Allen E. Inman powerhouse at the Bureau of Reclamation’s Minidoka Dam on the Snake River in south-central Idaho. GE Renewable Energy is responsible for that project.

“The system was originally developed almost 30 years ago,” Ronnie Oliver, project engineer for Wärtsilä Hydro & Industrial Services, told POWER. “It injects water into the sealing interface, which provides lubrication and a means of maintaining a positive pressure, so that silt and debris don’t get into the interface and wear it down quickly.”

In itself, that is not so unique; what is distinctive is that the latest version incorporates a large number of sensors, which glean information about seal operation and performance. With the information, predictive analysis can be performed in real time, telling owners how long replaceable components can be expected to last. In addition, if some type of anomaly or extenuating operating condition occurs, the effect on the seal can be determined immediately. That could help maintenance teams prepare for a future repair.

“There are systems around that are far more simplistic, and basically hydraulic, but to the best of my knowledge, we are the only company that has the technology that is sent digitally,” said Les Creak, general manager of the Hydro & Industrial Services segment for Wärtsilä.

A water filtration system can also be added to help extend seal service life. Wärtsilä tailors each design to meet the requirements of the facility. The filtration system is particularly important in heavy-silt, heavy-quartz waters. Creak suggested that the combined solution could significantly extend maintenance cycles.

“If you can move from three- to five-year cycles, all the way out to 10 years, then you are cutting costs and obviously optimizing the uptime in terms of power generation,” Creak said.

Staying on Top of Things

Complacency, or in some cases even neglect, can allow small problems to become large. Matt Roberts, engineering and operations manager for American Governor, told POWER that most original equipment is built to high standards and designed for very long life. He said due to the nature of how hydropower governors are designed, they can continue to function satisfactorily, even when not properly maintained.

“I don’t know how many times we’ve walked into a plant and the governor, short of being dusted off, barely gets touched,” Roberts said. “So one of the biggest challenges we have is just general awareness. A lot of times we don’t get called in until the governors are in incredibly poor shape.”

Roberts added that, although mechanical governors can provide excellent frequency control when properly maintained, in many cases the importance of the governor isn’t well understood by the utilities themselves. Without adequate training for plant staff, maintenance will suffer, eventually resulting in governor problems, such as difficulty synchronizing, hunting, and excessive governor oil pump runtime.

“One of the leading reasons we see companies upgrade to digital governors is simply a lack of in-house understanding of how to support their original equipment,” Roberts said.

However, mechanics can be taught how to perform all types of governor maintenance tasks, including major overhauls. American Governor offers such training at its facility in Amherst, Wis. Governor schools and focus classes include a combination of classroom and hands-on sessions (Figure 5) to give technicians the knowledge and skills that they need. American Governor also offers onsite training, covering plant-specific governor equipment.

Roberts suggested that all plants should have a governor training strategy and a preventive maintenance plan. With proper training, in-house staff can usually complete routine maintenance jobs without any trouble.

Big Jobs Could Require Help

When it comes time for major work, such as a five-year overhaul, some facilities have the staff to do the job, but others may want to hire a contractor. For example, American Governor has teams that do less-routine work regularly. For them, showing up onsite with a full parts kit, doing a top-to-bottom governor disassembly and inspection, replacing worn components along the way, and recalibrating the reassembled governor is just another day on the job. That is most likely not the case for in-house workers, who might only do such work a few times during their entire career.

Frequent technology changes and the loss of know-how—as experienced engineers and technicians reach retirement age—also calls for action. Rodney Orwick, president of Voith Hydro’s HyService division, suggested that the loss of experienced employees is one of the biggest challenges facing owners. He said that many times when the Voith HyService team is called to disassemble a unit, plant personnel tell them that no one working at the facility has ever seen the machine disassembled (Figure 6). Frequently, the staff doesn’t know the process, and often they don’t know where the original equipment handling fixtures are located, or if they even exist.

|

|

6. Haven’t been there or done that. Working on stator windings is not something the average maintenance technician does every day. Courtesy: Voith Hydro |

Voith claims to have installed a quarter of the world’s 40,000 hydropower units (Figure 7), which it feels is a big advantage. The company says that having the experience—and the original drawings—gives it a leg up on the competition. But if a company wants to go it alone, Voith can help them prepare.

|

|

7. Fine tuning. Getting a Francis runner ready for installation requires a lot of skill and attention to detail. Voith has been doing that type of work for a long time. Courtesy: Voith Hydro |

Voith offers training programs tailored to fit customer needs too. The company has expert instructors with solid experience that are available worldwide. Orwick said the company’s methodology alternates theory and practice, using exercises, case studies, simulations, and visits to factories and laboratories. The company also stresses the importance of reading the operations and maintenance manuals and following the original equipment manufacturer’s recommendations.

Changing with the Times

Orwick said that modernization programs could be driven by a wide variety of factors, including relicensing requirements, changes in plant usage, environmental mitigation efforts, a desire to increase capacity, and reliability or availability concerns. While each owner has its own threshold for pursuing upgrades, he said most are driven by cost-to-benefit ratios, that is, either reducing the cost of operation or increasing the benefits of generation.

“We have historically found that the all-in costs and payback periods of hydro modernization and life extension are quite often competitive with other options for owners to add capacity/energy, such as gas-fired generation,” Orwick said.

Both Orwick and Roberts pointed to functionality as another driving factor for upgrades. Roberts said there are just certain things that are quite a bit harder to do with a mechanical governor than with a digital system.

“Mechanical governors can’t really be reprogrammed,” Roberts said. “With a digital governor, it’s a blank slate. You can do anything. You can have remote operation. You can have diagnostics. You can send alarms back and say ‘this specific thing failed.’ You can change the operation.”

And while Roberts admitted that obsolescence used to be a significant problem for digital governors, he said that is not really the case anymore.

“One of the biggest advances in governor technology over the last 10 to 20 years has not been in functionality but in the type of equipment that’s been used,” said Roberts.

In the old “black box” days of digital governors, if a chip failed, the entire system might have required replacement. But now, American Governor uses all off-the-shelf, nonproprietary components in its digital systems. If something fails, any local industrial electrical supplier is likely to carry the replacement part that is needed.

“You’re seeing equipment lifecycles of 30 to 40 years already, with commitments from the manufacturers to support them for another 20 years,” Roberts said. “So you’re starting to see obsolescence periods that are getting closer to what the mechanical governors were.” ■

—Aaron Larson is a POWER associate editor.