Want Long-Term Energy Storage? Look to Hydrogen

The power industry has been all abuzz lately about the potential role hydrogen could play in decarbonizing the energy sector. POWER was quick to notice the excitement surrounding hydrogen, and launched HydrogeNext, a conference designed to cover the full hydrogen value chain from production to distribution and end-use. The inaugural show was held in conjunction with the Experience POWER event in San Antonio, Texas, Oct. 18–21, 2021.

Among the key takeaways from HydrogeNext was how important hydrogen could be in long-duration energy storage schemes. “A lot of people who are looking at green hydrogen—or hydrogen in general—are looking at it as a fuel,” Paul Browning, CEO of Mitsubishi Power Americas, said during a panel discussion on the opening day of the show. “We’re looking at it as an energy storage technology,” he said.

Browning acknowledged that it’s more cost-effective to store renewable power for short durations, such as two or four hours, with a battery energy storage system. However, when storing energy for a week, a month, or a season, hydrogen quickly becomes the preferable option. “In fact, when you get into those really long timeframes, it’s hundreds of times more cost-effective than battery energy storage,” he said. “So, to me, the relevant question is: ‘What does it cost relative to other storage technologies?’ And in that sense, it’s very affordable.”

Storing Hydrogen in Underground Salt Domes

A few years ago, Mitsubishi Power identified two projects that it thought could tie together nicely with hydrogen. One was the Intermountain Power Project. “It’s in Delta, Utah. It’s the last coal-fired power plant that’s producing power for the state of California. It’s scheduled to be retired in 2025. And it happens to be sitting right on top of a huge salt dome, which is exactly the kind of geologic formation that we need to store large quantities of hydrogen for long periods of time,” explained Browning.

Mitsubishi Power went to the Los Angeles Department of Water and Power, and the Intermountain Power Agency, with a proposal, and they ended up selecting Mitsubishi Power’s gas turbines to repower the plant. The new 840-MW facility will produce enough power to supply about one-fifth of the City of Los Angeles, and the gas turbines will be capable of using hydrogen for fuel.

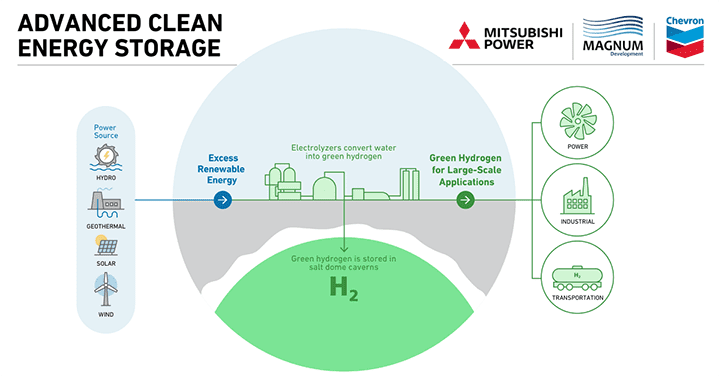

The hydrogen is expected to come from the second endeavor: The Advanced Clean Energy Storage project (Figure 1). In that one, Mitsubishi Power and its partners will use 220 MW of electrolysis to convert renewable power into green hydrogen, which will be stored in the big salt dome that the power plant sits atop. “We’re going to put two caverns—each one about the size of the Empire State Building—to store massive amounts of green hydrogen for long periods of time,” Browning said. The company estimates the caverns will each be capable of storing enough green hydrogen to provide 150 GWh of clean energy. It claims more than 40,000 shipping containers of lithium-ion batteries would be needed to produce an equivalent number of GWh.

Cryogenic Hydrogen Storage

As novel as the Mitsubishi Power projects are, there may be even more exciting work taking place across town from the company’s headquarters near Orlando, Florida. At the University of Central Florida, researchers are trying to prove the feasibility of an innovative hydrogen storage concept called a cryogenic flux capacitor (CFC). Although the name conjures up images of Doc Brown’s invention in the film “Back to the Future,” this technology could be much more important for the real-life future.

The project is based on a patent from NASA’s Kennedy Space Center (KSC). Work is being led by experts from the Southwest Research Institute (SwRI), and in addition to researchers from UCF, the team includes NASA KSC, Air Liquide, and Turbine Technology Services. The technology capitalizes on the energy storage capacity of liquefied gasses. By exploiting a unique attribute of nano-porous materials—aerogel in this case—fluid, such as hydrogen, can be stored in a molecular surface adsorbed state. This cryogenic fluid can be amassed at low- to moderate-pressure densities, on par with liquid, and then quickly converted to a gas when the need arises.

The goal of the project is to store as many fluid molecules as possible in the smallest, lightest-weight volume possible, and to supply those molecules rapidly on demand for end-use applications. This solution would reduce both safety-related logistics issues and the limitations of complex storage systems.

Currently, high-pressure gasses are stored in vessels with heavy, thick walls, which is effectively what the salt dome caverns offer. This type of storage requires constant pressurization and complex systems to limit boil-off. The CFC addresses these issues, simplifying current operations, and opening the possibilities for new applications and new markets from cryogenic liquid (Figure 2).

Aerogels are currently commercially available and have no significant barriers to production. Furthermore, scalability of materials is not an issue, as it may be for lithium-ion batteries as their scale-up continues. A module size would be defined to optimize the techno-economic performance for achieving a designated volume of storage (Figure 3). Estimates suggest that for a reference CFC plant of 100 MW power output with a 50% net thermal-to-electric efficiency, 100 hours of storage duration would require 9,090 cubic meters of space, which could easily be accommodated at most gas turbine power plants—a primary target market for the technology.

“The design of a prototype for demonstration is currently being developed by the entire team,” Jayanta Kapat, a Pegasus Professor and the director of UCF’s Center for Advanced Turbomachinery and Energy Research, told POWER. “While fabrication, testing, and demonstration will be performed at UCF [see sidebar], and techno-economic analysis for use of this technology will be performed by SwRI. If proven to be successful, this approach for hydrogen storage will be superior to other existing alternatives for integration into power generation infrastructures in terms of overall cost and ramp-up time.”

UCF a Leader in Hydrogen and Gas Turbine ResearchA lot of other research is being conducted to develop innovative hydrogen technology on campuses around the country. Much of it is being funded by the U.S. Department of Energy (DOE). For example, on July 7, 2021, the DOE announced it was awarding $52.5 million to fund 31 projects to advance next-generation clean hydrogen technologies and support the department’s Hydrogen Energy Earthshot initiative, which is expected to reduce the cost and accelerate breakthroughs in the clean hydrogen sector. UCF was awarded $800,000 in that round of funding. According to Subith Vasu, a professor in UCF’s Department of Mechanical and Aerospace Engineering, the funding will be used to solve hydrogen combustion challenges. “The funding is mostly for supporting students and costs associated with executing the experimental and computational work we intend on carrying out,” he told POWER. Vasu said the main challenges with hydrogen combustion involve reducing NOx emissions and solving issues related to flame flash back and autoignition. UCF is uniquely able to test a variety of power generation applications in its High-Pressure Extended Range Shock Tube for Advanced Research (HiPER-STAR) facility. HiPER-STAR allows studies to be conducted at extreme pressures (up to 1,000 bar), and it can handle realistic fuel mixtures similar to practical gas turbines, rather than highly diluted mixtures universities often use to study fundamental problems. Vasu explained why the high-pressure capability is important. “When you run realistic mixtures (high fuel loading), you run the risk of detonations, and the pressure can increase considerably (more than 10 times). Also, though traditional gas turbines operate near 20–30 bar pressures, the Allam cycle operates at 300 bar pressure, and we did a lot of work to help the industry realize the concept, such as at the NET Power facility—that effort mainly started with a previous DOE-funded project,” he said. Being based in Orlando, UCF has developed good relationships with gas turbine heavyweights Siemens Energy and Mitsubishi Power, which both have U.S. headquarters in the area. “Our partnership with Siemens Energy goes back to 2000, and is centered around a unique academia-industry research laboratory, named Siemens Energy Center,” Vasu said. UCF’s partnership with Mitsubishi Power is more recent, but has already produced results. In August, the team released an online “Power Generation NO Tracker” that uses data from the U.S. Environmental Protection Agency database as analyzed by UCF’s Center for Advanced Turbomachinery and Energy Research to show trends over time. “The NO Tracker is yet another effort by Mitsubishi Power to bring transparency to air quality issues during this energy transition and to highlight the industry’s progress,” Browning said in a statement when the tracker was launched. Vasu said UCF works with several other gas turbine original equipment manufacturers (OEMs) including GE, Solar Turbines, and Hanwha. “There are only a few universities in the country where there is a dedicated focus on gas turbines. Our students are readily hired by these OEMs and we are very well known for producing graduates who have gas turbine expertise,” he said. When asked why talk of hydrogen has become so prominent in energy circles today, Kapat responded, “There is no proverbial ‘silver bullet’ that can provide holistic and global decarbonization, especially since access to electricity is so integral to modern society, and is also closely connected to standard of living that many parts of the world are trying to improve. However, there is one potential technical solution that comes close to being the ‘silver bullet’ under most of the situations, and that is hydrogen.” Vasu added: “Hydrogen is a simple fuel that can solve both the energy and water crisis in the world, while at the same time help with reducing the greenhouse gas impact. Hydrogen can be produced in a variety of ways—green, blue, gray, etc. Hydrogen combustion produces water, and water is a precious commodity in many communities around the world.” ■ |

—Aaron Larson is POWER’s executive editor.