South Korean Companies Snap Up Opportunities to Advance Floating Nuclear, Nuclear Hydrogen, SMRs

Days after Korea Hydro & Nuclear Power (KHNP) announced it would participate in a consortium to develop floating nuclear power plants, the owner and operator of South Korea’s 25 nuclear power plants joined forces with TerraPower to bolster the demonstration and commercialization of Natrium, TerraPower’s sodium-cooled fast reactor integrated energy system.

The deals were announced this week as two other advanced nuclear reactor technology companies, NuScale and Ultra-Safe Nuclear Corp. (USNC) separately heralded development efforts with major South Korean entities to explore nuclear hydrogen and supply chain opportunities.

The efforts illustrate a concerted drive by the U.S. and South Korea to advance nuclear advancement and keep pace with several global imperatives. Along with lucrative opportunities presented by the expansion of the global nuclear reactor market, these imperatives include an urgent need for new, reliable zero-carbon energy sources, establishing energy security, and countering nuclear geopolitical influences, Kenneth Luongo, president and founder of the Partnership for Global Security, recently noted.

Industry Collaboration Ramps Up at Recent Event

Collaborative efforts between South Korea and U.S.-based companies have been gaining steam from government initiatives to encourage partnerships between the two countries, given both nations’ similar goals. The nations share similar ambitions to secure nuclear technology influence and export opportunities. The Yoon Suk Yeol administration, for example, is championing nuclear power plants as a “core pillar” of its exports, and it has set out a goal to sell 10 reactor units overseas by 2030. Both the U.S. and South Korea, however, face fierce competition from Russia’s and China’s nuclear industries, which are state-owned and financed.

But energy partnerships between the two companies remarkably ramped up at the Korea-U.S. High-Tech Industry and Clean Energy Partnership in Washington D.C. on April 25. At the event, 23 memorandums of understanding (MoUs) were signed between several notable energy players. South Korean companies include Doosan, Doosan Robotics, SK, HD Korea Shipbuilding and Offshore Engineering, Hyundai E&C, Lotte Chemical, Korea Electric Power Co., and KHNP. U.S. entities include Boeing, Rockwell, GE Vernova, Centrus Energy, TerraPower, NuScale, Holtec International, ExxonMobil, Plug Power, and Siemens. Agreements spanned several industries and energy area, including hydrogen, carbon neutrality, and nuclear power.

TerraPower Gets SK’s Backing to Demonstrate and Commercialize Natrium

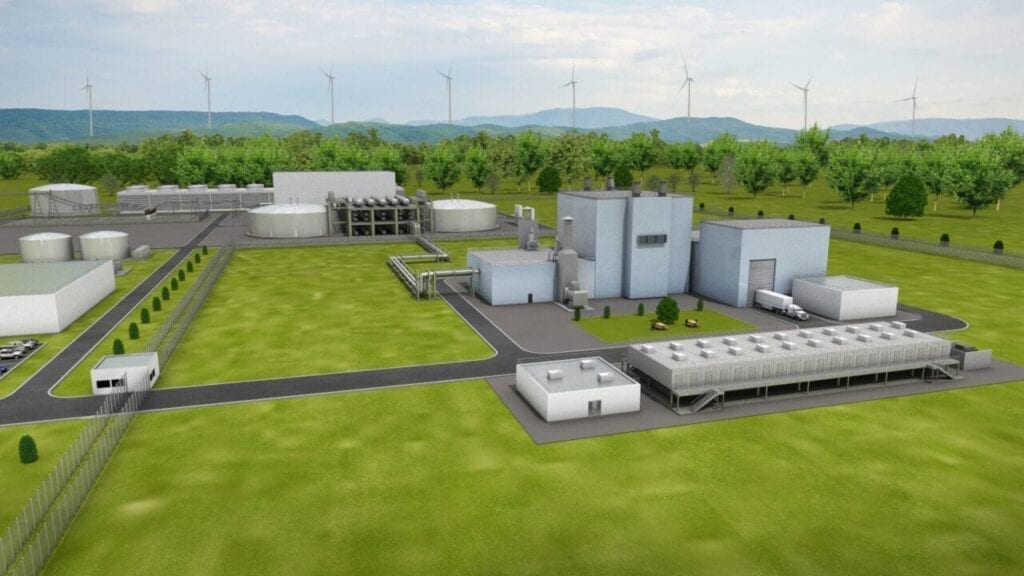

At the event on Tuesday, South Korea’s KHNP and SK, a massive industrial conglomerate, signed a strategic cooperation agreement with TerraPower to demonstrate and commercialize Natrium. Natrium technology, developed by TerraPower and GE Hitachi Nuclear Energy, comprises a 345 MWe sodium-cooled fast reactor (SFR) with a molten salt-based energy storage system that can boost the system’s output to 500 MWe for than five and a half hours.

A demonstration of the pool-type SFR system is notably already taking shape at the site of a retired PacifiCorp coal plant in Kemmerer, Wyoming, armed with $2 billion in federal funding under the U.S. Department of Energy’s (DOE’s) Advanced Reactor Demonstration Program (ARDP). The demonstration’s target completion date has been pushed back to 2030, owing mainly to fuel availability concerns. The effort already appears to be bearing fruit. On March 31, PacifiCorp. revealed it is mulling the addition of two more Natrium units to its generation resource mix by 2033.

“The world is searching for legitimate options to address the effects of climate change,” said TerraPower President Levesque on Tuesday. “Advanced nuclear, and specifically the Natrium reactor design, is poised to be a significant solution for our future energy needs. That is why leading companies like SK and KHNP are getting proactively involved in supporting this technology.”

SK and its energy and chemicals subsidiary SK Innovation, are already investors in TerraPower. The entities bolstered TerraPower with $250 million in August 2022. “With this agreement, SK has secured an opportunity to participate in TerraPower’s SMR project, and pioneer deployment opportunities with our mission to decarbonize global operations,” SK said in a statement sent to POWER.

KHNP Making Rapid Inroads on SMRs, Floating Nuclear

KHNP’s participation in the strategic agreement is also especially notable, given that the company, a wholly owned Korea Electric Power Corp. (KEPCO) subsidiary, is South Korea’s sole nuclear owner and operator.

KHNP also leads the country’s nuclear technology export efforts. Its main export product is the APR1400, a two-loop, evolutionary pressurized water reactor (PWR) design that evolved from the OPR1000 Korean Standard Nuclear Power Plant design and Combustion Engineering’s (now Westinghouse’s) System 80+ design.

The APR1400 design has so far been implemented at the United Arab Emirates’ (UAE’s) first nuclear power project at Barakah. KHNP is now pursuing development of a nuclear plant based on APR1400 technology in Pątnów, central Poland. The Korean Economic Daily on April 24 reported, citing the head of PGE Polska Grupa Energetyczna SA, that KHNP may soon sign a binding agreement for the project.

Other potential APR1400 export deals, including to the Czech Republic, however, have been stalled by an ongoing legal dispute with Westinghouse about technology transfer. KHNP has reportedly said it will work with Westinghouse to “prevent further complication of the issues pending in the case between Westinghouse and KHNP.”

KHNP’s advanced nuclear reach, however, extends beyond Westinghouse. Last week, KHNP notably formed a consortium with Samsung Heavy Industries (SHI) and Danish firm Seaborg Technologies to develop floating nuclear power plants of up to 200 MWe to 800 MWe.

Seaborg’s 2017-launched Compact Molten Salt Reactor (CMSR) comprises a 250-MWth/100-MWe molten salt reactor designed for use in modular floating nuclear power barges. The concept derives from Seaborg’s first reactor design effort, the Molten Salt Thermal Wasteburner (MSTW), a terrestrial 270-MWth/115-MWe molten fluoride salt reactor, which features a graphite moderator.

The consortium’s key objective will be to enable “timely commercialization and a scalable export of factory-produced CMSR-based floating nuclear power plants worldwide,” the consortium partners said in a joint statement.

Seaborg sealed a key partnership with SHI in April 2022 to manufacture and sell turnkey power plants “ready to be moored at industrial harbors and connected to the electric grid onshore.” The partners have also since launched an effort to develop hydrogen production and ammonia plants powered by CMSRs.

NuScale Inks Agreement for Global Supply Chain Development

NuScale, developer of VOYGR plants, on April 25, meanwhile, signed an MOU with Doosan Enerbility and the Export-Import Bank of Korea to support NuScale’s SMR deployment.

Doosan, South Korea’s giant engineering, procurement, and construction (EPC) company, has notably held an investment share in NuScale since 2019 alongside Nuscale’s majority investor Fluor Corp., and other investors, including Sargent and Lundy, ARES Corp., Oregon State University. Last year, the company also agreed to forge materials for NuScale’s SMRs to support the 462-MWe Carbon-Free Power Project (CFPP) in Idaho Falls—the first potential NuScale plant.

“The agreement outlines areas of cooperation, such as marketing, technical support, and further development of a global supply chain, and Doosan and NuScale commit to strengthening their cooperation to deploy NuScale VOYGR plants globally,” NuScale said on Tuesday. “Specifically, Doosan committed to helping establish a US-based supply chain for NuScale Power Module production through capacity expansion and manufacturing technology advancement.”

USNC and SK to Explore Nuclear Hydrogen Production

Seattle-based USNC, meanwhile, on April 20 signed an MOU with Hyundai Engineering and SK subsidiary SK ecoplant to jointly research and develop commercial “Hydro Micro Hubs” over the next five years.

The prospect is significant for USNC, a company that is developing the 5-MWe (15 MWth) Micro Modular Reactor (MMR), a high-temperature gas-cooled reactor, as well as a proprietary tristructural-isotropic (TRISO) Fully Ceramic Microencapsulated (FCM) fuel.

A “Hydrogen Micro Hub” is a facility that “produces hydrogen by applying a high-temperature electrolysis process of solid oxide electrolysis cells (SOEC) to the electricity and high-temperature steam generated by USNC’s [MMR],” USNC explained. “This is a carbon-free hydrogen production method that extracts hydrogen by decomposing water with electricity generated from nuclear power.”

The project will use an MMR slated to be demonstrated at the Chalk River Laboratories (CRL) site in Ontario, Canada. Hyundai Engineering will oversee the MMR-related balance of plant and EPC activities. USNC will be responsible for MMR design, manufacturing, and supply. SK ecoplant said it is slated to establish “a nuclear power-based hydrogen production system using Bloom Energy’s SOEC and supply hydrogen production equipment.”

“Compared to commercial pressurized water reactors, this technology can generate relatively high-temperature steam, enabling the use of SOEC operating at high temperatures, which can maximize hydrogen production efficiency with less energy,” USNC added.

For SK ecoplant, the opportunity offers a diversification of its assets into “pink hydrogen”—hydrogen produced with nuclear energy. The company has already tested hydrogen production through electrolysis using a 130 kW-scale SOEC facility located at the Bloom SK Fuel Cell manufacturing plant in Gumi, Gyeongsangbuk-do. The company notably developed a heat recovery system that went online at a unique 4.2-MW combined heat and power plant featuring Bloom fuel cells in June 2022.

“The company is also pursuing a project to convert green hydrogen into ammonia or methanol, which have high storage capabilities. It is evaluated as having a complete renewable energy-based green hydrogen value chain, from renewable energy project development to related equipment production and EPC to green hydrogen production,” SK ecoplant said.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine)