Smart Condition Monitoring of Flue Gas Analyzers in Power Plants

A web-based condition monitoring solution can help power plant operators quickly identify emissions gas analyzer problems, enabling timely corrections. The technology can also allow experts to monitor multiple sites remotely, adding flexibility to operations.

Electricity, water, and heat are such a part of our everyday lives that we only notice them when they’re gone. Energy suppliers ensure that we have a consistently high quality of life with these utilities. Modern waste incineration plants not only recycle waste, but also generate electricity and heat with low CO2 emissions. Gas analyzers are used to ensure environmentally friendly energy production.

The pollutants produced during combustion are filtered out with a complex gas cleaning system. An energy supplier with many locations in Europe monitors its emissions with gas analyzers from SICK. The SICK analyzers are critical components in the environmental compliance equation. Hot wet extractive measurement technology is utilized for this aggressive incineration process, which is laden with particulate and acid gases. A partial gas stream is taken from the exhaust gas and fed into the analyzer, which measures substances such as nitrogen oxides, carbon monoxide, carbon dioxide, moisture, ammonia, and acid gases with precision down to microgram concentrations per cubic meter.

The aim is to minimize downtime, because legislators in different countries impose strict emission requirements before approving a plant. For example, if the emission measurement system fails, the operator is threatened with large fines, or officials could even shut down the plant. This makes high availability of analysis equipment even more important.

Regular maintenance work ensures availability of the analyzers and therefore the emission measurement system. Consistent monitoring of the individual device components and operating parameters allows for easy replacements to the corresponding parts in time. This makes it possible to comply with the statutory measures for air pollution control with 97% emission measurement availability.

This process is often referred to as condition monitoring, specifically for gas analyzers. This large European supplier mentioned above uses condition monitoring in its waste incineration plants. As a result, the company can significantly increase the availability of its plant to better plan maintenance work in advance, helping to reduce maintenance costs.

Increased Plant Availability

To help both the user and the service provider plan maintenance in a more targeted manner and react even better to potential failures, the energy supplier uses a predictive maintenance solution to supplement its routine inspections, which are very time-sensitive. This digital service identifies critical condition changes quickly and proactively. This means service technicians can arrive on time and with the right spare parts. In many cases, the cause can be diagnosed remotely and the problem solved immediately, eliminating costly plant shutdowns.

|

|

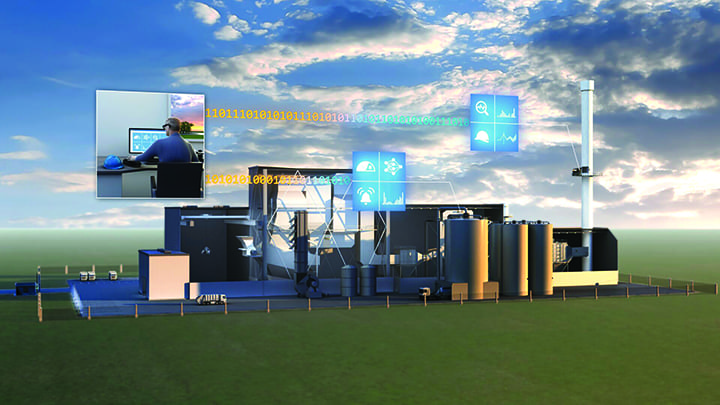

1. A web-based condition monitoring solution can help power plant operators identify gas analyzer problems quickly, allowing technicians to make corrections within the time limits established by regulators. Courtesy: SICK |

This is why the operating entity relies on a web-based condition monitoring solution (Figure 1). The physical monitoring box has an application-specific software package for the browser application that allows for simple monitoring of historical data, alarms, and the overall performance of the analyzer.

The current status of different assemblies is monitored through visualization and evaluation of vital parameters, such as supply voltage, and lamp and reference energy. An alarm is generated to indicate abnormalities, making it possible to react quickly and systematically. Vital parameters visualized in a histogram give an overview of the data in the progression. Drifts and trends of relevant parameters (such as cell flow, internal pressures, and temperature) as well as leaks or process-related contamination are easy to identify to help detect possible wear or device malfunction in the early states. The automated alerting function therefore shortens the response times in the event of damage.

|

|

2. On-site technicians can utilize an app to quickly and efficiently monitor gas analyzer performance. Courtesy: SICK |

On the dashboard, the service employee at the energy supplier can monitor in real time the condition of the gas analyzer and its functions or trace back in the history. Evaluation of the data history makes it possible to predict the service life of device components. Should the monitoring app (Figure 2) predict a malfunction, preventative action can be taken to prevent device downtime.

If predefined limit values are exceeded, an email with this information is automatically generated and sent to responsible parties. Field service experts can also proactively provide concrete recommendations for action when maintenance is required.

The vital, encrypted data is collected by the gateway device from the analyzers and sent to the cloud for processing via a cellular signal-equipped device, local area network (LAN), or wireless local area network (WLAN). This data can be hosted on a provided cloud network, the customer’s cloud server, or a local server on-site. This allows important changes in the device condition to be visualized using device-specific monitoring apps and the gathering of data from multiple sites. This means a large collection of assets can be monitored remotely, giving a comprehensive overview of the status of all analyzers.

Monitoring Multiple Sites

Analyzer technicians are often responsible for multiple sites or analyzers. Web-based condition monitoring allows them to avoid going to each individual site to determine the status of each analyzer. Instead, routine checks can all be done remotely and someone can be dispatched to the site only if necessary. Some sites can operate unmanned and it helps to eliminate the necessity of having full-time crews at each site.

In addition, power plants in remote locations, such as coal-fired or gas-fired power generation plants using flue gas analyzers, often have limited staff that is only getting more limited due to cost-cutting measures and labor shortages. Having remote access allows one person to monitor multiple sites, without being in front of the analyzers. It enables the worker to maintain maximum analyzer availability so units remain in compliance with permits and avoid any data gaps. When monitoring multiple sites, that worker can ensure the power plant complies with Environmental Protection Agency regulations to avoid potential fines.

Condition Monitoring for Increased Uptime

Determining the most important variables for condition monitoring and data analysis help to develop a suitable predictive maintenance model for the condition of the most sensitive component groups. A large number of malfunctions can be predicted with high precision using condition monitoring technology. For example, enhanced component aging and increased wear on consumable parts can be detected in advance, allowing parts to be ordered and installed before they fail.

In addition, the ongoing data analyses make it possible to continue to develop the physical monitoring box that lives on-site. This results in even more precise predictions with increased uptime, and these can be extended to include additional applications. This also increases the availability of the measured values and significantly reduces plant downtime. ■

—John Calame is a market product manager for Process Automation with SICK.