New Technology Offers Options for Floating Offshore Wind and Power-to-X Projects

New technology is regularly being developed and enhanced to improve power delivery and incorporate more renewable energy into systems. ABB Energy Industries is among the companies investing in solutions to make future power systems better. Among its current focus areas are deploying subsea power distribution and conversion concepts to support the floating offshore wind industry, and renewable Power-to-X projects, including the world’s largest dynamic green Power-to-Ammonia pilot project.

“We have a lot of experience—over 20 years—with this subsea equipment,” Asmund Maland, head of subsea and offshore power at ABB Energy Industries, said as a guest on The POWER Podcast. “Our intention is to put on the seabed what we call the ‘services substation and collector systems,’” he explained. Maland said the subsea equipment could replace or act as an alternative to a floating substation, which he expects will be more needed as the offshore wind industry moves to deeper waters.

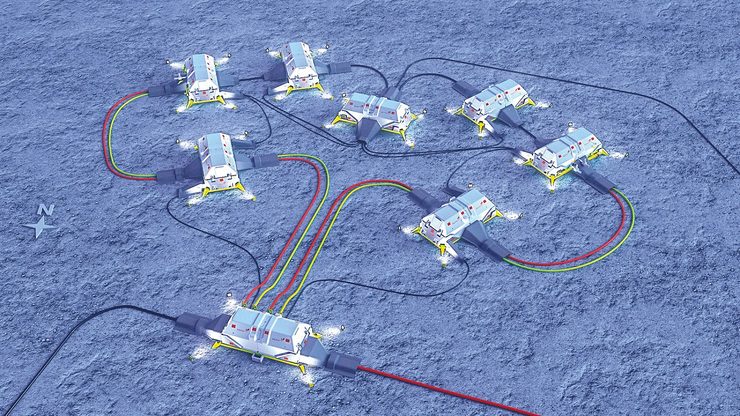

ABB has already tested these systems for the oil and gas (O&G) industry with great early success. Nearly a decade ago, the company initiated a $100 million Joint Industrial Project with Equinor (formerly Statoil), Total, and Chevron with support from the Research Council of Norway. As part of that project, ABB completed the development of an electrification system for transmission, distribution, and conversion of power, to subsea pumps and gas compressors, at a peak capacity of 100 MW, to water depths up to 3,000 meters, with transmission distances up to 600 kilometers, and with little or no maintenance for up to a lifetime of 30 years (Figure 1).

Maland noted that deep-water subsea equipment must be pressure compensated. For example, subsea transformers are liquid-filled with all air and gas voids eliminated. The pressure-compensating system keeps the internal pressure close to that of the outside water. “The result is that the wall thickness of the transformers and other equipment can be thinner and use less material,” he explained.

“If you replace a floating substation with something on the subsea, you will reduce to one-fifth of the steel. So, by that, there is also then potential capex [capital expenditure] savings of maybe over 30%, and also, the opex [operating expense] savings of the year will also be quite good,” said Maland.

Some of ABB’s competitors also see promise in subsea technology, which Maland said offers some sense of security that the company is on the right track in working to develop the technology. “You cannot always be sure that you have the right ideas if you’re alone, but if several companies see the same potential, it kind of increases the chances that this will happen,” he said. ABB expects to be ready to take orders for subsea floating offshore wind systems (Figure 2) by the end of 2024.

On the podcast, Tom Zøllner, head of ABB Energy Industries for Denmark, talked about another innovative project ABB is involved in, which the company calls “the world’s first dynamic green Power-to-Ammonia plant.” ABB is working alongside Danish companies Skovgaard Energy, Vestas, and Haldor Topsoe to demonstrate Power-to-X (PtX) technology in Lemvig, northwest Denmark. The project is also being supported by the Danish government’s Energy Technology Development and Demonstration Programme, which provided about $12 million in assistance.

“The reason behind the project is that in Denmark we have for some time been one of the lead countries when it comes to green energy, and it has been more and more clear that we need to figure out how to store all this additional energy that we may not be able to use all the time. Unfortunately, batteries are not strong enough, and therefore, we need to look into alternatives, and Power-to-X has become one of the solutions that we have been looking into for some time,” Zøllner said.

The demonstration facility—scheduled to start operating in 2024—will be powered by renewables from 12 MW of existing wind turbines and 50 MW of new solar panels. ABB is responsible for electrical integration and advanced process control of the full Power-to-Ammonia plant operating in highly dynamic mode. The 10-MW plant is expected to operate at full capacity when excess wind and solar power are available, but will gear production down when neither renewable energy source is present, making it adaptable to fluctuations in energy supply and different from other types of PtX plants, which are directly connected to the grid.

The pilot plant will produce about 5,000 tons of ammonia per year. While the project is small in the grand scheme of things, Zøllner said it will showcase the technology and should be scalable in the future. The ammonia from this project will be used for heavy transportation, but Zøllner expects future plants to supply the fertilizer industry, as well as heavy industry and other transportation sector uses including on boats and ships.

“A lot of the technologies are already on the market, it’s just a matter of how to put this together to have an efficient plan. This is new for all of us,” said Zøllner.

To hear the full interview with Maland and Zøllner, which includes a discussion of other innovative offshore wind cabling and substation strategies, how the learnings from Europe could benefit offshore wind development in the U.S., speculation on how electrification and carbon capture could alter the power landscape, and more, listen to The POWER Podcast. Click on the SoundCloud player below to listen in your browser now or use the following links to reach the show page on your favorite podcast platform:

For more power podcasts, visit The POWER Podcast archives.

—Aaron Larson is POWER’s executive editor (@AaronL_Power, @POWERmagazine).