New Environmental Rules Keep Pressure on Coal-Fired Generation

New U.S. Environmental Protection Agency regulations affecting the nation’s coal power plants are routinely in the national news. The latest proposed rule focuses on the release of carbon dioxide into the atmosphere. With a substantial amount of coal generation expected to be shut down (up to 40 GW to 50 GW in the coming years by some accounts), the new regulations are increasing the likelihood that this lost capacity will not be replaced by new coal generation.

On March 9, 2012, the U.S. Environmental Protection Agency (EPA) formally released a proposed regulation (Prevention of Significant Deterioration and Title V Greenhouse Gas Tailoring Rule Step 3, GHG Plantwide Applicability Limitations and GHG Synthetic Minor Limitations) to the Greenhouse Gas (GHG) Tailoring Rule. The proposal upholds limits put forth in 2010 when the regulatory process began. On April 13, 2012, the EPA formally released a proposed rule (Standards of Performance for Greenhouse Gas Emissions for New Stationary Sources: Electric Utility Generating Units, the “Carbon Pollution Standard”), pushing new pulverized coal plants to move toward the efficiency of a supercritical design with carbon capture and storage (CCS) technology. Together, the promulgated GHG Tailoring Rule and proposed new source carbon regulation will put a substantial strain on an already aging coal fleet and will negatively impact the economics of new coal power generation.

Industry found little relief from a federal appeals court, which decided a case in late June that consolidated dozens of challenges to the EPA’s endangerment finding along with its Tailoring Rule. A three-judge panel of the U.S. Court of Appeals in Washington ruled on June 26 that the EPA properly concluded that greenhouse gases are pollutants that endanger human health. The court also found that opponents lack the legal right to challenge rules determining when states and industries must comply with regulations curtailing emissions of those gases.

More than 90 lawsuits challenging the regulations were consolidated into four, and arguments were heard over two days in February. The parties argued over the EPA’s finding that GHGs are pollutants that endanger human health. The judges also heard arguments against a 2010 rule on motor vehicle emissions that opponents said improperly sets standards for stationary sources such as steel mills and power plants.

The court considered challenges to the EPA’s Tailoring Rule, which limits the number of businesses covered by carbon regulation and phases in controls. The EPA argued that the Tailoring Rule is acceptable under the Clean Air Act and necessary to keep states from being overrun with permit requests.

It was unclear whether industry would appeal the ruling, either by asking the full Appeals Court to consider the case or by seeking Supreme Court review. An appeal could add further delay and uncertainty to regulations covering greenhouse gases.

Carbon Pollution Standard Limits

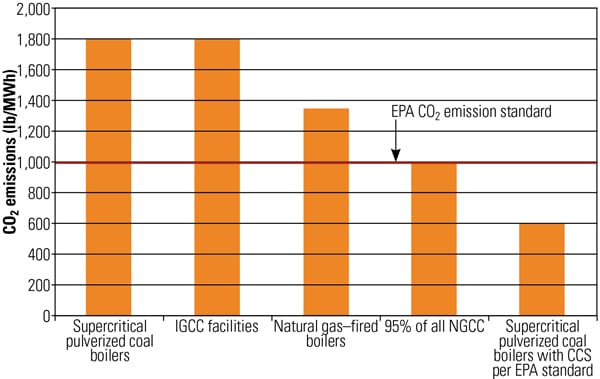

Exactly how the EPA has been able to affect electric generating units utilizing coal as their primary fuel and not natural gas combined cycle plants is described in the method the agency used to calculate its proposed carbon dioxide (CO2) limitation. In the proposed rule, all new stationary sources will be required to meet an emission standard of 1,000 pounds of CO2 per megawatt-hour. This standard would be applied to any new electric generating unit larger than 25 MW. The EPA chose this limit based on data analyzed from 2006 to 2010, where 95% of all natural gas combined cycle plants, not designed as a combined heat and power facility, met this standard.

The EPA’s analysis also shows that it expected the most efficient large-scale commercially proven steam cycle for a coal power plant—a supercritical steam cycle—would emit approximately 1,800 lb CO2/MWh. For those wishing to invest in less-costly conventional subcritical coal power plants, the emission rate will worsen. Thus, the limit for CO2 has been set very low, ensuring that natural gas combined cycle (NGCC) plants will readily meet this rule while coal power is left struggling to comply.

Even with CO2 emission rates for supercritical pulverized coal plants much higher than the rule allows, coal power plants can still be constructed. Coal plants that obtained preconstruction permits prior to proposal of the regulation and that begin construction before April 13, 2013, will not be affected. However, for all other sources wishing to utilize coal, additional control technology will be required.

CCS technology—a feasible but not currently economically viable technology, nor one used on the scale needed by the power industry—will be required to be implemented in order to meet regulatory standards. The EPA in its proposal has provided the option to operate at the higher supercritical emission rate for a period of 10 years. However, emission rates for the following 20 years must be no more than 600 lb CO2/MWh to make the 30-year average 1,000 lb CO2/MWh. Figure 1 offers a comparison of CO2 emission rates for various types of power plants.

|

| 1. Carbon condition. Comparison of CO2 emission rates from various types of fossil-fueled power plants. Source: EPA |

Although the purpose of this provision may have been to provide additional time to develop the technology required for coal plants to comply, it ultimately results in capital equipment being more expensive than necessary. That’s because the EPA assumes that in a 10-year time frame, CCS will become a readily available technology with costs lower than what they are today. However, even if this assumption were correct, the equipment would need to be significantly oversized to deliver emissions results at levels far below the regulatory standard to maintain compliance. This would result in a significant amount of extra capital expenditure and a higher operating cost in the form of auxiliary load and maintenance.

From a permitting standpoint, this rule has a direct effect on the technology selection for pollution control through the best available control technology (BACT) process. BACT is an in-depth analysis applied to facilities subject to Prevention of Significant Deterioration (PSD) permitting on a case-by-case basis that considers energy, environmental, and economic impacts to control pollutants. The process itself is performed in five steps: identify all potentially applicable control technologies, eliminate infeasible options, rank remaining technologies by effectiveness, evaluate the most effective technologies, and propose BACT. Unless other technologies move to gain commercial acceptance quickly, the further development of CCS may be the only technology to satisfy BACT.

This latest round of regulations also will affect other power systems, such as natural gas–fired boilers. A typical value for CO2 emissions from natural gas–fired boilers is estimated at 1,350 lb CO2/MWh. The EPA justifies setting an emissions limit below this type of power generation by stating that “it seems unlikely that utilities would choose a natural gas–fired boiler as the generation technology of choice when [natural gas combined cycle] is a much more efficient, less expensive, and more widely used technology.”

Although this broad statement may be true for large utilities, it doesn’t necessarily apply to other power generators. Independent power producers, agricultural cooperatives, and industrial users are normally significantly smaller in size. Any of these groups that wish to generate 25 MW or more may no longer consider a natural gas boiler without CCS to generate steam. The EPA indicates that an analysis was performed (but not provided for review) considering the economic impacts on these entities. The results concluded that implementing this rule would impose no significant impact on these power producers.

Integrated gasification combined cycle (IGCC) plants convert a solid feedstock (coal) into a gaseous fuel (syngas) that is used to drive a combined cycle power plant. Already an expensive option, this form of power generation also will not meet the proposed regulation. It is expected that IGCC plants will emit the same amount of CO2 into the atmosphere as a pulverized coal supercritical plant. Because its emission rates will not meet the standard, a precombustion system to separate CO2 in the high-pressure syngas to meet the 1,000 lb CO2/MWh standard will be required.

Greenhouse Gas Tailoring Rule

Closely related to the New Source Performance Standards (NSPS) for electric generating units is the already promulgated Greenhouse Gas Tailoring Rule. Announced on June 3, 2010, the rule was put in place to regulate GHG emissions in three phases. Unlike the NSPS, which regulate only CO2 emissions, the GHG Tailoring Rule regulates emissions of multiple greenhouse gases. In addition to CO2, methane, nitrous oxide, hydrofluorocarbons, perfluorocarbons, and sulfur hexafluoride are grouped into the category of GHGs and must be accounted for as PSD pollutants, which are assigned a CO2 equivalency value (CO2e).

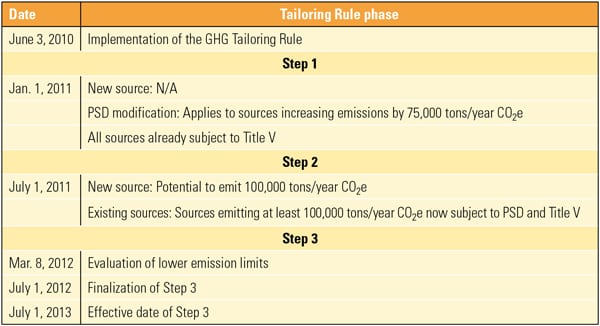

According to an EPA news release, GHG regulations were to be implemented in a three-stage process. Table 1 shows a timeline for implementation and GHG limitations of the various phases along with the anticipated final acceptance date of all portions of the rule. The limits included in this regulation are much higher than typical PSD limits. Typical PSD limits are set at 100 tons/year (t/yr) for sources falling under one of 28 listed source categories and 250 t/yr for all other sources. Setting the CO2e limits much higher than the existing PSD limits is due to the inherent nature of GHGs emission rates being significantly larger than all other PSD pollutants. Because of this, the rule had to be “tailored” to include GHGs in the PSD permitting process. As part of the third stage, the EPA was to reevaluate the limits imposed by the original regulation and determine if any benefit would be realized by further lowering the limits.

|

| Table 1. Tight schedule. The deadline for implementing the GHG Tailoring Rule is coming soon. Source: EPA |

The potential lowered limit would have included all new sources emitting more than 50,000 t/yr CO2e to be categorized as PSD sources. This would have forced a multitude of sources that typically would have been permitted as minor sources to be subject to the PSD regulations. The EPA determined that at this time there would be no additional benefit from a further reduction in emission thresholds and that the rule promulgated in 2010 should be maintained.

Plants that currently fall under PSD permitting and participate in Title V programs of the Clean Air Act are affected by this regulation. For the Title V program, this applies to both new and existing operating permits. Existing facilities will be required to address GHGs if a modification to the facility triggers a PSD review during the term of the permit. From a GHG standpoint, a PSD modification is one that increases the net emissions by 75,000 t/yr CO2e. If it doesn’t, then GHGs will have to be addressed when renewal of the Title V permit occurs.

This is critical because the likelihood of power generating facilities needing to address GHGs at some point during their service has greatly increased. Unlike the NSPS for CO2, CCS has not been determined to be the default technology of choice. For those facilities that trip PSD thresholds, GHGs will need to be addressed through the detailed case-by-case BACT analysis outlined above.

Due to the sizable number of permits expected by the EPA that will be required to address GHGs, the agency is currently developing presumptive BACT for GHGs. This presumptive BACT as defined by the EPA is a “standardized BACT for certain emissions units.” As noted in the proposed update to Step 3 of the GHG Tailoring Rule, very few permits have been issued addressing GHG emissions. In fact, as of Dec. 1, 2011, only 18 permits nationwide had been issued with a GHG provision.

Because of the lack of permits that address GHG emissions, there has not been a determination of presumptive BACT. Those permits that have been issued to address GHGs have held that plant efficiency is the most effective method for reducing GHGs, with some permits requiring a minimum plant heat rate to be maintained.

Achieving Emissions Targets Through Plant Efficiency

For a coal plant, the requirement of a more stringent plant maintenance program to uphold a minimum plant heat rate may be considered BACT at this time.

Congress established the New Source Review (NSR) permitting program as part of the 1977 Clean Air Act Amendments. NSR is a preconstruction permitting program that serves two purposes:

- First, it seeks to ensure that air quality is not significantly degraded from new and modified factories, industrial boilers, and power plants.

- Second, it seeks to offer assurances that any large new or modified industrial source will be as clean as possible and that advances in pollution control occur side by side with industrial expansion.

NSR specifies three types of permitting requirements. A source may have to meet one or more of these permitting requirements:

- PSD permits, which are required for new major sources or a major source making a major modification in a so-called “attainment area.”

- Nonattainment NSR permits, which are required for new major sources or major sources making a major modification in a nonattainment area.

- Minor source permits.

When Congress passed the Clean Air Act, the electric utility industry argued that its oldest plants should be exempt from new limits, saying that those plants would likely be replaced by newer plants built under PSD and subject to BACT. Congress granted existing facilities “grandfather status” that shielded them from the more stringent emission control requirements. This meant that routine maintenance, repair, and replacement activities were excluded in the regulations from being a physical change that could trigger PSD.

But although PSD excludes routine maintenance, repair, and replacement activities from triggering PSD, the regulations also stopped short of defining “routine.” Industry kept many older plants up and running and so avoided the need to decommission and replace them. Many of these older facilities remain in operation today and have never been required to meet Clean Air Act requirements.

The best guidance to define “routine” maintenance came from the court case known as Wisconsin Electric Power Co. (WEPCO) vs. Reilly. The case came about after WEPCO planned a retrofit project on existing coal-fired boilers. In 1988, WEPCO sued the EPA for failing to grant a PSD exemption under the routine maintenance, repair, and replacement provisions. The court’s decision (known as the “WEPCO rule”) outlined a test for routine that used five factors: nature, extent, purpose, frequency, and cost of an improvement project. But this outline still stopped short of offering a clear definition of “routine.” The effect is that NSR discourages plant improvements that might increase efficiency, which is the goal of the EPA’s recent GHG rulemaking.

A second court case ( U.S. et al. v. DTE Energy Company and Detroit Edison Company)—this one involving Detroit Edison’s Monroe Station—led to still more requirements for power plant operators. That utility made efficiency improvements to a steam turbine, but because it was a non-routine modification, it had to prove for five years after the changes were made that actual emissions from the combustion turbine did not increase above PSD thresholds.

The result is that if efficiency improvements enable a unit to be run more often, PSD may be tripped. On the one hand, this discourages many efficiency improvement projects that could help reduce overall emissions. On the other hand, it encourages the seemingly perverse decision to maximize emissions as much as possible in the years before an efficiency improvement project. By doing so, the operator improves the likelihood that its future emissions will be no worse after the efficiency improvements than they were before.

The bottom line is that since practically nothing is considered by the EPA to be “routine maintenance,” almost any change at a plant is potentially subject to PSD. This makes operators justifiably wary of making efficiency improvements. Environmental groups benefit from the confusion because the vague definition of “routine” and accompanying standards provides them with a substantial stick to wield against a utility. So although the EPA’s GHG rules view efficiency improvements as BACT for compliance, the longstanding record of often ambiguous and sometimes hostile precedent works counter to those goals.

Efficiency Improvement Gains

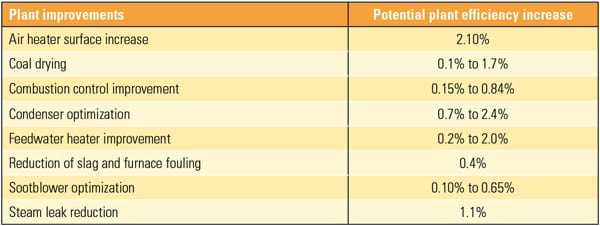

Table 2 lists some common improvement projects along with typical efficiency gains. For the hot gas path, increased sootblowing or online furnace cleaning to minimize slag formation will work toward this goal. Reducing slag and furnace fouling also can be achieved by magnesium hydroxide injection. Maximum reductions in slagging and fouling can increase plant performance by 0.4%.

|

| Table 2. Plant improvement and potential increase in plant efficiency. Source: Reducing CO2 Emissions by Improving the Efficiency of the Existing Coal-fired Power Plant Fleet, NETL, 2008. |

A regenerative air heater with better seals or new baskets will reduce air leakage and increase heat transfer, resulting in better combustion performance. Removal of excessive ash buildup in the air heater also will increase heat transfer while reducing the pressure loss and saving on auxiliary power (Figure 2). The increase in effective surface area of the air heater can lead to plant efficiency improvements up to 2.1%.

|

| 2. Plugged solid. Excessive ash buildup in a regenerative air heater can severely reduce the boiler combustion efficiency. Courtesy: KBR |

Increased heat transfer efficiency for steam condensers, feedwater heaters, cooling towers, and closed cooling water systems all support increased plant efficiency. Optimizing an existing condenser can increase plant efficiency from 0.7% to 2.4% while improvements to the feedwater heating system can add an additional 0.2% to 2.0% to plant efficiency. Ensuring that rotating equipment is operating at its best efficiency point and that material-handling systems are optimized help to reduce auxiliary plant loading. Energy losses through electrical equipment such as transformers also should be evaluated to minimize plant losses.

Reducing the amount of steam and energy lost through boiler tube leakage is another critical plant improvement. Replacing defective tubes can increase overall plant performance by 1.1%. Analyzing combustion performance and upgrading control systems to better measure and control fuel also will result in increased plant performance. Increases in plant performance of between 0.15% and 0.84% can be experienced by this upgrade. Additionally, better combustion controls can have the added benefit of reducing the formation of nitrogen oxides and carbon monoxide.

In case a more stringent plant maintenance program is unacceptable as BACT, additional measures may be taken to ensure a minimum heat rate is achieved. These may include the addition of heat transfer area in the economizer section, additional sootblowers to reduce slag formations, or fuel switching to a lower-moisture-content fuel, resulting in better boiler efficiency. The addition of sootblowers or optimized sootblowing techniques has the potential to add another 0.1% to 0.65% to plant efficiency. If possible, waste heat from various sources could be utilized to “dry” a fuel source to achieve better combustion performance. Such fuel drying has the potential to add another 0.1% to 1.7% to plant efficiency.

In all these cases, however, maximum efficiency and best heat rate is typically achieved at full-load operation. During startup and shutdown, provisions will be needed to exceed accepted plant efficiency. Upset conditions that require the plant to operate at partial load also will be problematic for achieving maximum plant efficiency. It is quite undesirable and inefficient for large coal plants to be required to shut down due to heat rates not being met at part-load operation.

Under Pressure

Already under a substantial amount of pressure from the EPA’s recently finalized Mercury and Air Toxics Standard and the litigated Cross-State Air Pollution Rule, coal power has increasingly been the subject of much environmental scrutiny. With another round of proposed environmental regulations designed to implement CCS and limit the release of CO2, the likelihood of a new coal power plant being constructed in the U.S. would appear to be minimal. The GHG Tailoring Rule remains active and ambiguous as to what BACT will be for greenhouse gases. Combined, these regulations leave coal-fired generation in a much less attractive position than natural gas combined cycle plants.

— Brandon Bell, PE ([email protected]) is a principal mechanical engineer with KBR Power and Industrial, Chicago.