MHI Prepares to Test J-Series in Japan

Mitsubishi Heavy Industries (MHI) has begun converting a combined-cycle plant in Japan to prepare for verification testing of its long-anticipated J-Series gas turbine in February 2011—a system that the company claims has the most power generation capacity and highest thermal efficiency in the 1,600C turbine inlet temperature class (Figure 3). The work being carried out at the Takasago Machinery Works facility in Hyogo Prefecture (where the company’s G-Series gas turbines were tested) includes installation of the J-Series turbine, and it marks another major milestone in the technology’s development.

|

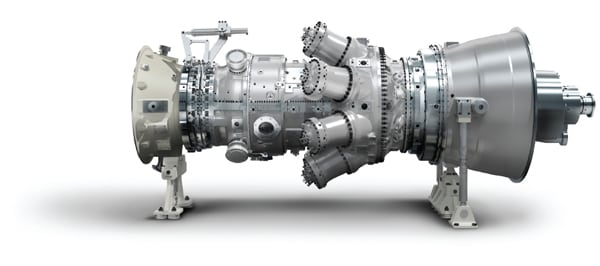

| 3. Cramming it in for a test. Mitsubishi Heavy Industries (MHI), a company that completed development of its long-anticipated J-Series turbine last year, says it has begun installation of the 1,600C-class turbine for verification testing at a combined-cycle plant at its Takasago Machinery Works facility in Hyogo Prefecture. The 60-hertz J-Series reportedly achieved a rated power output of 320 MW and an “unprecedented” 460 MW in gas turbine combined-cycle power generation applications. Courtesy: MHI |

The company finished developing the turbine last year, and it says it has since been focusing efforts on its commercialization. According to MHI, the turbine is able to withstand temperatures of more than 100 degrees—more than the top-of-the-line 1,500C-class G-Series turbine. The 60-hertz J-Series gas turbine also reportedly achieves a rated power output of 320 MW and an “unprecedented” 460 MW in gas turbine combined-cycle (GTCC) power generation applications, in which heat-recovery steam generators and steam turbines are also used. The 60% gross thermal efficiency of the turbine, moreover, makes it the world’s most efficient GTCC, MHI claims.

MHI says it has already started working on projects that call for delivery of the J-Series starting in 2011, but it also continues to push the product onto the global market. Meanwhile, it says it will closely watch testing of the new turbine not only to verify that it can operate over the long term but also because results could spur development of an even higher-temperature turbine.

Interest in the technology in Japan is surging. Mostly due to climate change concerns, the country, already a major consumer of natural gas (it has more than 40 liquefied natural gas terminals and produces double its import capacity domestically), is seeing more gas-fired power plants being built.

But MHI’s efforts to send the J-Series to market are perhaps being harried by competitor Siemens Energy’s announcement just six months earlier, in June 2010, that after a nearly decade-long development phase, its H-class turbine was commercially available. Describing the SGT6-8000H, which boasts 60% efficiency, Siemens called the 60-Hertz turbine a “masterpiece of engineering.” Florida Power & Light will be that model’s first customer, and Siemens expects to sell at least 10 turbines a year in the medium term.

Yet, of late, Siemens has been focusing on the midsize industrial gas turbine market, for which it foresees “a marked increase in demand,” particularly for turbines with ratings of between 35 MW and 40 MW through 2020.

This November, the German company released a 37-MW industrial gas turbine—the SGT-750 (Figure 4)—a machine designed to be employed in simple-cycle and combined-cycle power plants for baseload, standby, and peak-shaving applications. According to Siemens, the twin-shaft turbine—which attains an efficiency level of 40%, the company claims—uses components from other gas turbines. It also uses a dry low emission combustion system to cut nitrogen oxide emissions. A less-discussed but key advantage of the turbine is that maintenance work can be performed on site, minimizing downtime. Siemens said, “Maintenance downtimes for this machine have been cut to a mere 17 days in 17 years.”

|

| 4. A 35-MW to 40-MW sweet spot. Siemens Energy released a 37-MW industrial gas turbine this November, saying that the machine is designed to be employed in simple-cycle and combined-cycle power plants for baseload, standby, and peak-shaving applications. The company foresees a “marked increase in demand for turbines with ratings of between 35 MW and 40 MW through 2020. Courtesy: Siemens Energy |