How to Effectively Minimize Power Plant Water Usage

Power plants across the U.S. are working to minimize water use in order to comply with regulatory requirements and offset the growing cost of water. This article offers some important recommendations to manage the effect of water and wastewater minimization on steam cycle and plant operation.

Water scarcity is a significant challenge in many parts of the world, and a lack of available fresh water creates substantial planning challenges for the water-intensive power industry. The limited availability of fresh water may make it more difficult to build new power plants or make it difficult for existing plants to meet electricity demand. In recent years, water shortages and high temperatures have caused reductions in electricity production at power plants in the U.S. and abroad. State authorities are placing pressure on industrial users to minimize fresh water usage and, in some cases, cease fresh water usage entirely.

Most industrial users have undertaken water and wastewater minimization efforts as a consequence of economic, environmental, and/or regulatory drivers. While well-intentioned, in some cases these efforts increased process risk at facilities and adversely affected the ability to consistently and reliably operate. Power plants have been particularly affected.

A host of design features decrease water use and bolster recycled power plant waste streams, but what’s the outcome? While water usage is reduced, there’s often an uptick in significant challenges for steam cycle and plant operations.

Water Conservation Trends, Misconceptions, and Options

Lack of available fresh water hasn’t changed the laws of thermodynamics. It takes the same amount of evaporation to cool a condenser in 2017 as it did in 1975. Power demand, however, has increased approximately 219%, and water usage at power plants has increased similarly.

Wet-Cooled Power Plants. It’s important to remember that streams suitable for recovery represent, at best, less than half and generally less than 30% of the total water used at a typical wet-cooled power plant. Traditional wet-cooled power plants lose 60% to 90% of their incoming water via cooling tower evaporation or drift. Although some work has been done, no industrial-scale technology for evaporative loss capture exists. Cooling tower evaporation as well as drift, steam losses, and combustion turbine inlet air cooling evaporative losses cannot be readily recovered using available technology.

Marginal technological improvements to purification and other treatment systems have occurred over the past few decades, as well as more widespread deployment of recovery equipment (brine recovery systems, for example). Cooling water chemical treatment has improved significantly, allowing cooling towers to operate at higher cycles of concentration. These improvements can minimize wastewater discharge significantly, but have a relatively modest effect on water usage. While wet-cooled towers achieve laudable reductions, an air-cooled condenser uses no cooling tower makeup water at all and produces no cooling tower wastewater. The water reduction achievable with a wet-cooled tower cannot approach the water reduction associated with air cooling.

Air-Cooled Power Plants. Air cooling significantly reduces fresh water usage, but even air-cooled plants use some water, typically for auxiliary cooling and steam cycle makeup. Brine recovery systems can be installed to recover a significant portion of this water, but some fresh water is still consumed.

Recycled-Water Power Plants. Recycled water typically consists of secondary effluent from a wastewater treatment plant that has been treated further (tertiary treatment) to remove suspended solids (clarification/filtration) and to disinfect (oxidizing biocide and contact basins). Only recycled water can reduce plant fresh water usage to essentially zero, and it’s an option that should be considered for any new power plant regardless of the cooling technology employed. Regulations in many states, particularly in the Southwest, basically require new facilities to use recycled water and encourage existing plants to switch if recycled water is available.

Two Power Plants Compared

Living in perpetual drought—the norm in the Western U.S.—requires tough choices in power plant water systems design. A look at two combined cycle power plants in the region highlights various design features that minimize water usage to the maximum extent possible. Both plants employ air-cooled condensers and evaporative coolers. One plant (Plant A) recovers low total dissolved solids (TDS) waste streams using simple filtration. The other (Plant B) recovers all wastewater (high and low TDS streams) using a combination of membrane filtration, reverse osmosis, and thermal concentration. Inspections at both plants revealed flow-accelerated corrosion in both the air-cooled condensers and in the drums of the low-pressure heat recovery steam generators (HRSGs).

Plant A recovers and reuses evaporative cooler blowdown and quenched HRSG blowdown via a reclaim water tank. In turn, the tank feeds the plant’s leased demineralization system and the plant’s wet surface air coolers (WetSACs). Total plant wastewater flow is 28.4% of total plant makeup flow.

Plant A’s water efficiency comes at a cost. It experiences steam cycle chemistry challenges, iron transport issues, air-cooled condenser corrosion issues, auxiliary cooling corrosion and deposition issues, and lower thermal efficiency during warm or hot weather. Air-cooled condensers don’t cool condensate as well as open recirculating cooling systems.

Plant B uses several reclamation systems not employed by Plant A. Dissolved solids are removed as demineralization system reject concentrates in a wastewater reverse osmosis system. Wastewater reverse osmosis reject is evaporated in a brine crystallizer. The distillate is recovered and returned to the plant’s ultrafilter feed mixing tank for reuse.

The salt is trucked off-site. Suspended solids are removed as filter backwash is recovered via a liquid-solids separation device. Sludge is removed via a filter press, and the solids are trucked off-site.

Recovered water, with suspended and dissolved solids removed, is returned for reuse. Water from the suspended solids removal process returns to the plant’s raw water/fire water storage tank. Water from the TDS removal process returns to the plant’s ultrafilter feed mixing tank and combines with several other recycle streams. The desire to reclaim most plant wastewater required the installation of an additional ultrafiltration unit and the recovery systems described above.

Plant A Versus Plant B

The water balances of both Plant A and Plant B were normalized to allow side-by-side comparison of their water savings potential. Unrecoverable water losses from both plants are the same at 96.8 gpm.

|

|

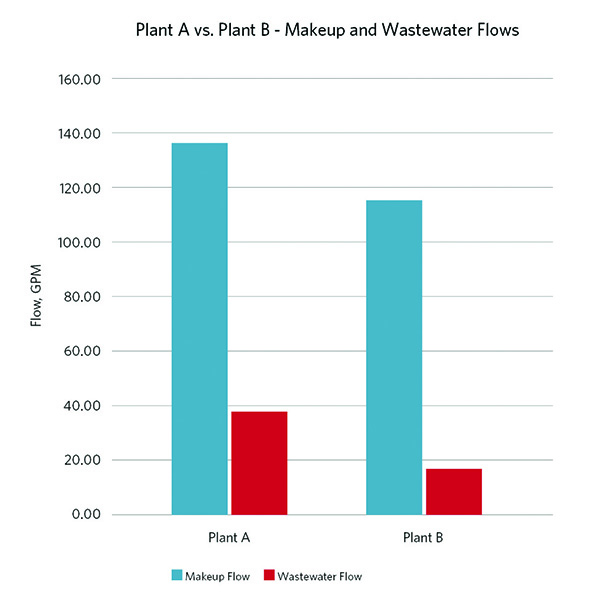

1. This bar chart shows the makeup and wastewater flows in gallons per minute (GPM) for two plants: A and B. Although B has lower flow in both areas, that is achieved using a far more complicated system costing millions of dollars in additional capital and operating expense. Courtesy: HDR |

What’s different between Plant A and Plant B?

- ■ Plant A’s total wastewater flow (all discharges) is 28.4% of total plant makeup flow. Plant B, using a far more complicated wastewater reclamation system, has a total wastewater flow of 16.1% of total plant makeup flow (Figure 1).

- ■ Plant B saves roughly 12% more water, but the savings are achieved at a cost of millions of dollars in additional capital and operating expense.

- ■ Plant B requires a total plant makeup flow of 8.4% of the makeup flow to a comparable wet-cooled plant. Plant A’s makeup flow is 9.8% of a comparable wet-cooled plant. Thus, the installation of complicated waste recovery systems for Plant B saved 1.4% more water than Plant A when compared to a traditional wet-cooled plant of the same size.

In terms of actual raw water usage and wastewater discharge, the greater water efficiency of Plant B appears less significant. Plant B’s relatively modest increase in water efficiency comes at a price. This plant experiences similar steam cycle chemistry challenges, iron transport issues, air-cooled condenser corrosion issues, and auxiliary cooling corrosion and deposition issues as those of Plant A. In addition, Plant B experiences significant challenges with its suspended solids removal, brine recovery, and demineralization systems.

Reviewing what worked well (and what did not) at both of these facilities leads to important recommendations specific to water and wastewater minimization strategies.

Design for Water Scarcity Based on the Location. Plant thermal design, water supply, and wastewater discharge options dictate water systems design. Some commonalities do exist, and their potential operational impacts should be clearly understood.

Recycled Water Is the First Choice. Recycled water should be used to the maximum extent possible. It has no effect on fresh water sources and is relatively drought proof. Recycled water coupled with a traditional wet-cooled condenser maximizes versatility from a water management perspective. Recycled water eliminates fresh water usage with the exception of potable water for sanitary and kitchen services.

Discharge limits may require reclamation of cooling tower blowdown, but these reclamation systems (or brine recovery systems) are problematic at best and should be avoided if at all possible. These systems cannot tolerate deviations from their design chemistry, require expensive cleanings at least annually, do not turn up or turn down well, are complicated, and require significant supervision and maintenance. Further, the large parasitic load, particularly for thermal systems, adversely affects heat rate.

Air-Cooled Condensers Are Another Viable Option. Air-cooled condensers represent a good second choice regardless of the makeup water source, and they can reduce fresh or recycled water usage by approximately 90%. Corrosion and iron transport control require diligent adherence to the industry consensus on best practices for monitoring and chemistry. Complex reclamation systems should be avoided if the plant design includes an air-cooled condenser, because they provide little benefit in terms of additional water recovery, and significantly increase costs and operational headaches.

Think Critically About the Sequence of Operations. Lack of a cooling tower significantly affects plant water management. Even small amounts of water can become problematic when there’s no large “sump” (cooling tower basin) to equalize flow and chemistry. In such cases, the plant’s sequence of operations becomes important. Design water balances should include realistic startup and shutdown scenarios, and typical operating conditions to ensure that adequate tankage and treatment systems are installed to support cycling operation.

Custom Engineer Auxiliary Cooling. Lacking a large cooling tower also complicates auxiliary cooling—to the point it should be custom engineered. The WetSACs typically employed have created operational headaches at many plants. Most of these operational challenges could be eliminated by installing WetSAC cells over a single, larger basin with a common chemical feed and control system.

Consider Additional Treatment for Brine Recovery Systems. To remove accumulating organics, brine recovery systems may require additional treatment. Most systems include suspended and dissolved solids removal processes, but very few address the issue of concentrating organics and their effect on steam cycle chemistry. If a plant employs a cooling tower, the best use of high-purity water recovered from plant brine is as cooling tower makeup. Demineralized water for steam cycle makeup should be produced using raw water. Lacking a cooling tower, some reclaimed water must be used to produce demineralized water, and proper management of organics becomes critical.

As water scarcity drives decreasing water use in power plants, it’s increasingly challenging to produce electricity. Considering options to minimize water use is essential to remaining in operation. As design features are incorporated to reduce overall water usage and increase recycled power plant waste streams, complex challenges arise for steam cycle and plant operations. Taking a variety of options into consideration, and gaining a thorough understanding of their effects, is a critical step in continuing to provide electricity. ■

—Dan Sampson is principal technical consultant at HDR.