How Low-E Valves Can Reduce Costly Fugitive Emissions

Though discussions of fugitive emissions are not new in power and processing facilities, they remain a focal point of most plants’ operational plans because they can harm profitability if they are not addressed. As governmental agencies like the U.S. Environmental Protection Agency (EPA) aim to curb fugitive emissions, it becomes ever more important to make sure plants comply with the latest regulations.

Regardless of a plant operator’s familiarity with the topic of fugitive emissions, it is crucial to understand the basics of the problem and how best to deal with them.

What Are Fugitive Emissions?

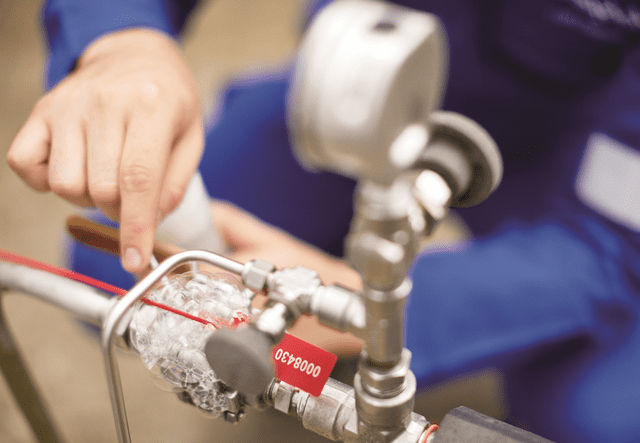

Sometimes leaks occur even in the best-maintained process equipment. When volatile organic compounds (VOCs) like benzene, methane, and ethanol escape into the atmosphere, they are called fugitive emissions and can cause problems with air quality and lead to the formation of ozone. They can also put unsuspecting employees at risk, which is why the government is putting measures in place to prevent them (Figure 1).

Fugitive emissions are most likely to escape at the dynamic and static seals on valves, pumps, and flange connections. Purchasing and installing low-emission (Low-E) valves can significantly reduce the amount of fugitive emissions allowed by any given system. The key is to install them before they are required by a legal agreement after violations have been discovered.

Enhanced LDAR and Low-E Valves

One action item plants can take to avoid being sanctioned for fugitive emissions is to institute an enhanced leak detection and repair (LDAR) program and purchase Low-E valves proactively. An enhanced LDAR program will allow plants to lower fugitive emissions by:

- Instituting a comprehensive plan, whereby, leaks are identified through in situ testing of valves and other connections using EPA Method 21.

- Identifying, documenting, and repairing leaks within a defined time frame.

- Lowering allowable leak limits for valves, connections, and pumps.

Most LDAR programs also require that all subsequent valves, whether they are used to repair existing systems or are part of new projects, must be Low-E valves. The question, then, is how to determine what constitutes a Low-E valve according to current best practices. In most cases, the manufacturer will offer proof that its valve is Low-E with one of the following actions:

- A written guarantee that the valve will not leak above 100 parts per million (ppm) for five years.

- A written guarantee, certification, or equivalent documentation that the valve has been tested pursuant to generally accepted good engineering practices and has been found to be leaking at no greater than 100 ppm.

Though it may seem like an easy solution is to accept the former, the question of liability should be considered carefully. If a valve covered by such a guarantee were to leak at more than 100 parts per million within the five years, plant operators must decide if the risk is worth it. The EPA can fine noncompliant plants up to $10,000 per day per incident and no plant wants to be responsible for that potentially significant financial penalty.

The better solution, from a plant operator’s perspective, is to have documentation indicating that the valves have been tested pursuant to the highest industry standards that accurately reflect what occurs in the field (Figure 2). There are three generally accepted tests developed by the American Petroleum Institute (API) and the International Standards Organization (ISO) that can provide more certainty that Low-E valves will perform in accordance with manufacturer claims. These tests include:

- API 624, Type Testing of Rising Stem Valves Equipped with Graphite Packing for Fugitive Emissions, covers the testing of rising stem valves using methane as the test media. The valve must perform 310 cycles as well as three thermal cycles (when the valve is tested at ambient temperature, an elevated temperature, then again at ambient temperature) with a leak rate under 100 ppm methane.

- API 641, Testing of Quarter-Turn Valves for Fugitive Emissions, details the testing of ball valves using methane as the test media. Each valve tested must perform 610 cycles as well as three thermal cycles with a leak rate under 100 ppm methane.

- ISO 15848-1, Industrial Valves — Measurement, Test and Qualification Procedures for Fugitive Emissions, gives the procedures and requirements for the mechanical and thermal cycle testing of valves with leak tests at various points. Methane or helium is used as test media.

In a perfect world, third-party laboratories will perform these tests instead of the valve manufacturer because of the potential for bias. Manufacturers who are willing to put their valves through the rigors of third-party testing demonstrate confidence that their valves will perform as expected. Once these independent tests are performed, the manufacturer should provide appropriate documentation, including a seal from the third-party laboratory, the location of the tests, and the verified results.

Get Ahead of Emissions Requirements

It does not matter whether a new process system is being built or whether a plant is trying to augment its LDAR program. In today’s world of strict environmental regulations, Low-E-certified valves should be chosen to keep fugitive emissions under control. By purchasing Low-E valves before they are mandated, plants can avoid costly retrofitting once the system has been built and can keep them in compliance with the most up-to-date environmental best practices (Figure 3). Clearly specifying Low-E valves can provide plants with the security of preventing fugitive emissions while protecting the environment and operational integrity.

When choosing a supplier for Low-E valves, it is critical to find one that fully understands specific systems and can provide the widest possible variety of valves—process, instrument, ball, needle, rising plug, and bleed valves—that meet the applicable API low-emissions requirements without needing to be modified. Finding a supplier with the knowledge and understanding necessary to guide the process from the design stage to completion is also an enormous advantage.

Low-E valves will eventually become a requirement as governmental oversight into fugitive emissions becomes more intense. It will be better for plants to implement them now as part of a thoughtful system design rather than have them imposed afterward with costly consequences.

—Randy Rieken is market manager for Swagelok Company.