Four Projects Picked to Speed Up Pumped Storage Hydro Construction

Four projects have won a competition launched by the Department of Energy (DOE) in April 2019 to help shorten the commissioning time for pumped storage hydropower projects and revitalize the hydropower industry.

The grand prize winners or the Furthering Advancements to Shorten Time (FAST) Prize competition were selected by the National Renewable Energy Laboratory (NREL) and the DOE’s Office of Energy Efficiency and Renewable Energy Water Power Technologies Office (WPTO) on Oct. 7. The DOE launched the competition, along with several other initiatives, during the National Hydropower Association’s annual conference in April in an effort to help the flailing industry counter stiff competition from wind and solar.

When the DOE launched the competition, Daniel Simmons, assistant secretary of the DOE’s Office of Energy Efficiency, and Renewable Energy (EERE) said the prize sought up to three winners that would provide solutions to “reduce the time it takes to commission pumped storage hydro from its current 10 years to less than five years,” collecting up to $550,000 in combined cash prizes and voucher support between November 2019 and September 2020. The DOE also envisioned that solutions would address non-regulatory challenges that pumped storage hydro developers face when deploying new projects such as significant upfront capital costs and “a lack of market certainty.”

Opening the Flow to Avoid Stagnancy

About 95% of all utility-scale energy storage in the U.S. currently comes from pumped-storage hydro. The nation has about 40 operational pumped storage plants with a combined capacity of 22 GW. But the DOE estimates that in the near-term, hydropower generation could grow only 9.4 GW through 2030, while approximately 16.2 GW in new pumped-storage hydropower could also become available.

The industry notes, however, that the value of hydro and pumped storage hydro’s flexibility and reliability attributes are not fully understood. Like hydropower, the flexibility of pumped storage hydro has been historically constrained by the interaction of the turbines, the dam, the water flow, and the institutional agreements—and this has become increasingly critical as markets evolve to embrace more, potentially cheaper, wind and solar power. “This results in sub-optimal designs and equipment, attrition of existing hydro resources, and stalled investments in new pumped storage hydro,” the DOE says.

The agency’s national labs are currently compiling a methodology guidebook and tool to improve pumped storage hydro valuation under different system conditions, and it soon plans to release several reports and white papers that will shed more light on pumped hydro’s role in transmission planning, cost and performance compared to other energy storage technologies, and market participation under the Federal Energy Regulatory Commission’s Order 841.

The FAST Prize Winners

The FAST Prize, which is a $2 million, multi-lab effort to conduct industry relevant analysis and bolster industry driven concepts and technologies to reduce the time to commission pumped storage hydro, is also a major facet of the DOE’s efforts. “It is the first of its kind and structured to provide support through full business concept development,” the DOE noted.

While open to accept submissions for only about six weeks, the prize structure combined a pitch contest—which was held on Oct. 7—with technical support. “The grand prize winners were selected from a group of nine concept stage winners, who were given three months and 50 hours of in-kind technical support from the partnering DOE National Laboratories, including NREL, Argonne National Laboratory, Oak Ridge National Laboratory, and Pacific Northwest National Laboratory, to develop their ideas,” the DOE said on Monday.

The winners are:

- First place: Reducing PSH Excavation Duration, Cost, and Risk. This project, submitted by individual competitor Tracy Livingston, combines excavation equipment modifications and process optimizations to achieve up to 50% reduction in excavation timelines. Livingston will win $80,000 in cash and $100,000 in voucher support from the national labs.

- Second place: Use of Modern TBMs for Underground Pumped Storage. Submitted by Doug Spaulding, Nelson Energy and Golder Associates, this project proposes use of tunnel boring machines for underground excavation, which can decrease excavation time by 50% and reduce costs. This team will win $60,000 in cash and $100,000 in voucher support.

- Third place: Accelerating PSH Construction with Steel Dams. Gordon Wittmeyer and Southwest Research Institute’s submission presented a modular steel concept for dams that cuts costs by one-third and cuts construction schedules in half. This team will win $10,000 in cash awards and a $100,000 in voucher support.

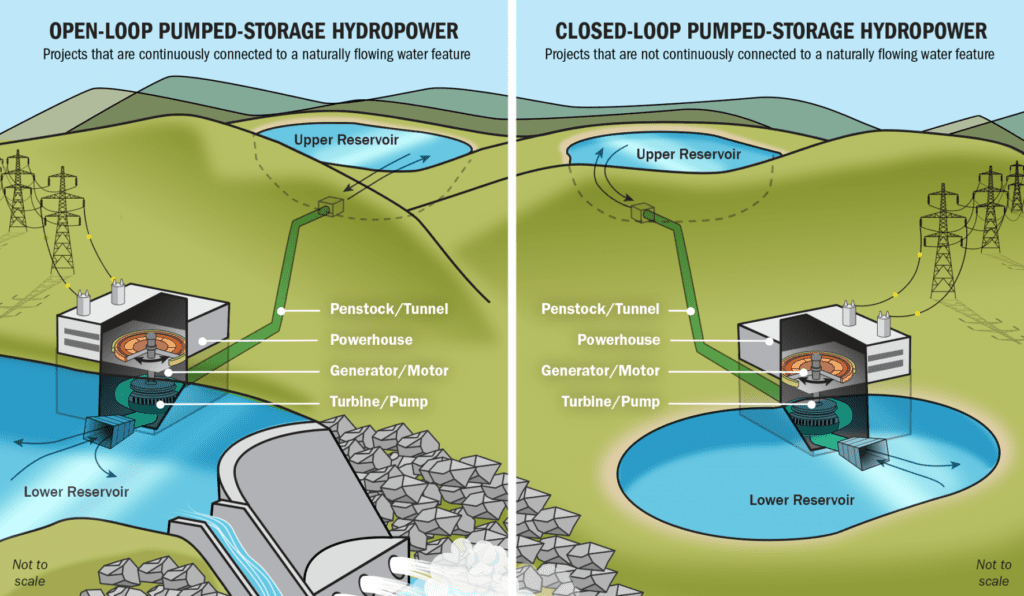

- Fourth place: Modular Closed-Loop Scalable Pump Storage Hydro. Tom Eldredge and Hector Medina from Liberty University presented a modular closed-loop, scalable PSH system with a capacity range of 1 to 10 MW, adaptable to sites without natural bodies of water. The team will win $100,000 in voucher support.

The DOE revealed the winning projects live on Twitter, noting that the final selections were “very difficult” to make. However, details of the winning projects are sparse, and POWER will update this story as they are provided.

— AmericanMadeChallenges (@AMCprizes) October 7, 2019

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine)