Fire Protection Guidelines for Handling and Storing PRB Coal

The Powder River Basin (PRB) Coal Users’ Group has developed recommended fire-prevention practices/guidelines for plants that burn PRB coal by itself or in blends. The guidelines are not equipment-specific because the physical layouts of coal-handling facilities vary significantly and because all fires are unique. The guidelines also are not comprehensive; their purpose is to recommend general practices that must be adapted for the specific needs of your plant.

The guidelines provide information about three areas: fire prevention and detection, firefighting equipment and training, and firefighting.

Fire Prevention and Detection

Operators familiar with the unique requirements of burning PRB coal will tell you that it’s not a case of “if” you will have a PRB coal fire, it’s “when.” The prevention of fires and explosions is the foremost objective for any plant burning PRB coal. Although prevention is cheaper than repairing fire and explosion damage, its costs always seem difficult to justify.

Fire prevention must be addressed in the following areas.

Housekeeping. Housekeeping means controlling dust and preventing spills. For example, float dust must be contained within transfer points and spillage from belts must be minimized. The accumulation of PRB coal below a conveyor or on conveyor parts can contribute to spontaneous combustion. Float dust either in the air or settled on beams, pipes, conduits, equipment, and fixtures provides fuel for explosions. A manual, daily washdown with a hose is beneficial, but it generally is not totally effective in removing PRB coal debris from under conveyors or from overheads (Figure 1).

1. An extreme case of PRB coal accumulation at the tail of a conveyor not designed for PRB coal. Courtesy: Utility FPE Group Inc.

Fixed washdown systems designed for 100% coverage are commercially available, greatly reduce labor costs, and significantly improve housekeeping over manual washdown. Plants that have installed these systems report being satisfied with their performance.

Preplanning. For planned outages, operators should take every precaution to ensure that all idle bunkers and silos are completely empty and verify that by visual checks. Bunkers and silos should be thoroughly cleaned by washing down their interior walls and any interior structural members—but not their horizontal surfaces.

Idle bunkers and silos that contain PRB coal should be monitored frequently for signs of spontaneous combustion by using CO monitors, infrared scanning, or temperature scanning. Don’t rely just on your senses—by the time you see or smell burning coal, a fire is already under way (Figure 2).

2. Immediate response is required when an odor of coal roasting or burning is detected coming from a silo, bunker, or hopper. Delays in taking action only allow the rate of burning to increase. Courtesy: Utility FPE Group Inc.

Some plants inert bunkers/silos of PRB coal with carbon dioxide (CO2) when they are expected to sit idle. For this practice to be effective, the enclosure must be completely sealed—especially the bottom cone, because CO2 is about 1.5 times heavier than air. The amount of CO2 needed to effectively inert an enclosure is 3.3 pounds per cubic foot, so a silo measuring 22 ft in diameter and 55 ft high would require 3.2 tons of CO2. A bulk supply of CO2 and an extensive piping system for bunkers/silos may be necessary to implement this system.

Bunker and Silo Design. An active bunker or silo typically doesn’t experience a fire under normal operating conditions. If a fire occurs while the bunker is actively moving coal, the bunker may have design irregularities that are contributing to coal bridging or some kind of stoppage. PRB coal is notorious for hiding within cracked weld joints and then spontaneously combusting.

Although the construction of bunkers and silos differs from plant to plant, they share one function that is independent of age and design: maintaining the mass flow of PRB coal. When raw coal is loaded into a bunker or silo, size segregation begins to take place. Large chunks of coal tend to roll out to the periphery of the bin while smaller chunks and fines stay in the center. This size segregation facilitates air migration up along the sides of the bunker/silo. It also presents a practical firefighting challenge when using water applied from above: Water tends to “rathole” through voids and can bypass the seat of the fire. Design changes in older plants may be required, such as eliminating flat bottoms in bunkers and obtaining free flow through bottom cones. If you don’t have mass flow conditions, we recommend that you perform an evaluation of the cone’s lining.

Access to the interior of bunkers and silos for firefighting is one of the most important aspects of successful fire suppression and one of the most difficult to obtain. Ease of access is often severely limited; the PRB Coal Users’ Group recommends that you preplan how to access hard-to-reach spaces. You may need to install access ports around the bunker/silo and at various levels (Figure 3).

3. A firefighting access port retrofitted to a bunker not designed for PRB coal. Courtesy: Utility FPE Group Inc.

Silos that are taller than 50 ft should be provided with access ports at various elevations to accommodate the injection of firefighting agents. The specific location of these ports must be determined by analysis of the silo’s design. Although directly attacking a fire using a piercing rod is most effective, using a rod on a fire in a silo taller than 55 ft is extremely difficult. You should consider installing a fixed hazard mitigation system zoned to apply an agent only at levels expected to be fire-prone. Use infrared thermography to locate fires and to determine the zone(s) that should be activated.

Fire and Gas Detection. A major consideration in minimizing the impact of fire is deciding where to install gas- and/or temperature-monitoring devices in bunkers and silos. Each type of instrument has its own application criteria that must be considered, but both have proven effective at early detection of fires at plants burning PRB coal.

CO Monitoring. Monitoring for the presence of carbon monoxide is the way to find out soonest whether there is a fire in the making. CO is an odorless, toxic gas that is liberated at the very early stages of incomplete combustion. CO is flammable at 12% to 75% volume in air (OSHA’s permissible exposure limit for CO is 35 ppm at an 8-hour time-weighted average). Though it may be normal to experience a rise and fall of background levels of CO in bunkers and silos during normal operation, monitoring will provide notification if the gas begins to continually trend upward from background levels. Desired alarm set points can be determined after the normal background level of CO is determined for your particular plant. The best way to make use of CO monitoring is to watch for a continuing upward trend of CO rather than to wait for the level of CO to reach a specific set point.

Thermal Monitoring. Thermal detection, using thermocouples, also can provide an indication of a fire inside a bunker or silo. However, thermal detection will not provide the early warning that CO monitoring does. Thermal detection relies on the presence of heat to activate, so a fire may already be of considerable size before the thermal detector senses the excess heat.

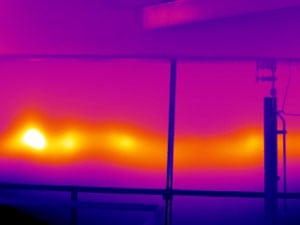

Infrared Scanning. Coal is a very good insulator, so a deep-seated fire may not produce extremely high temperatures on the exterior surfaces of a silo or bunker. Periodic monitoring of the bunker or silo using an infrared thermographic camera to scan the outside and/or inside of the enclosure is a common practice. Such a scan (Figure 4) provides a visual picture of the thermal condition of the coal and is especially helpful in pinpointing the exact location of a hot spot deep inside a silo or bunker.

4. A thermographic image of a PRB coal silo fire. The fire, shown by the lighter horizontal strip, follows a weld seam around the contour of the silo. The fire layer is approximately 5 ft in depth and is about 12 ft below the surface of the coal. Courtesy: Utility FPE Group Inc.

Firefighting Equipment and Training

Dealing with a fire inside a bunker or silo is a dangerous business that must be addressed with the correct equipment and training. There are two recommended methods for fighting a silo or bunker fire: using a fixed system installed inside the enclosure and/or using a special tool called a piercing rod. Experience indicates that the very best method of attack is to get the extinguishing agent directly to the seat of the fire. With proper preplanning, you will usually have plenty of time to deal with the fire if you have an organized and thoughtful game plan.

Fixed Hazard Mitigation Systems. Fixed (permanent) systems installed inside bunkers or silos must be designed specifically for that enclosure. Such systems are not fire-suppression systems per se. They are hybrids that can be used for dust control and housekeeping or activated to deliver an extinguishing agent in the event of fire. The downside of fixed hazard mitigation systems is that they must flood their entire enclosure with the agent to have any chance of reaching the fire’s hot spot (Figure 5).

5. This hazard mitigation system installed inside a silo sprays a combination of water and F-500. Courtesy: Utility FPE Group Inc.

Silos taller than 55 ft should be zoned so the extinguishing agent can be directed to any section of the silo susceptible to fire. The zoning also may require activating a zone discharge at the level just above the fire. It is recommended that the mitigation system be prepared to deliver a mix of water and a micelle-encapsulating agent.

Manual Firefighting Tools. Experience has shown that the best method of extinguishing a fire is to get the agent directly to its seat. To do this, you have to know the location of the fire within the enclosure, have access to the enclosure, and have the proper tools to deliver the agent.

The primary tool used to deliver agent directly to a hot spot is a piercing rod (Figure 6). These rods are designed to pierce the surface of the coal and be manually maneuvered to the hot spot. The benefit of piercing rods is that they can be used to inert the bunker or silo atmosphere by spraying the sides and the surface of the coal with agent prior to storing it.

6. An emergency response team gets basic training on using a piercing rod on a coal pile fire. Courtesy: Utility FPE Group Inc.

The rod is assembled in 5-ft sections. But the longer the rod, the harder it is to maneuver it inside the enclosure. Rods are generally made of stainless steel and come in several diameters (3/4 inch, 1? in., and 1? in.). The tip of the rod is perforated and cone-shaped, which allows it to be inserted easily deep into the coal and used at any angle. The rod can be inserted through the top or the sides of the enclosure if access ports have been pre-installed.

Using a fire hose to stream water through the top of a bunker or silo is definitely not recommended. Nor is using a stream to “drill” into the coal in an attempt to reach the fire. This technique most likely will stir up the coal and dust and result in a flash explosion inside the bunker or silo. A secondary explosion can also occur outside the enclosure as the heat ignites float dust in the air.

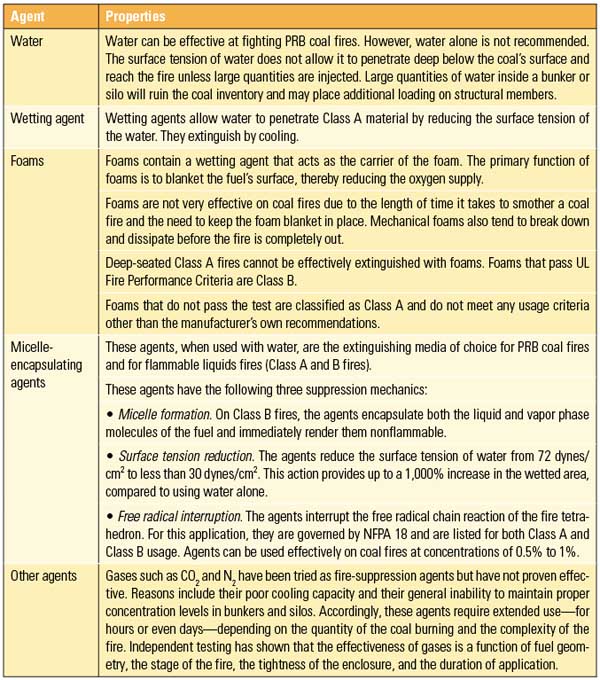

Fire Extinguishing Agents. Many extinguishing agents are suitable for use on coal fires. The table describes the extinguishing properties of several.

Properties of typical firefighting agents. Source: Utility FPE Group Inc.

Plant Fire Training. When a fire does occur, an operator’s first instinct will probably be to try and fight it. It is strongly recommend that no one without proper training of at least the structural fire brigade level attempt to put out a fire in a bunker, silo, or hopper. Personnel who have been trained at the incipient fire brigade level or lower are not properly trained to fight such fires. Municipal utilities that may be exempt from complying with OSHA training regulations should not exploit that status by avoid proper training. OSHA’s 1910.156 Fire Brigade Standard delineates the training levels.

Dialing 911. Some plants rely on the services of their local fire department. However, be cautioned that most municipal fire departments are not prepared to deal with a PRB coal fire. It is strongly recommended that the plant sponsor specialized training for local fire departments on the specifics of PRB coal and other major fire hazards found within the plant.

Firefighting

The PRB Coal Users’ Group recommends a three-step approach to firefighting. The three steps are summarized below; full details are available in the guidelines, which are posted on the group’s website.

Develop an Action Plan. This step entails initial investigation of the suspected fire, performance of a thermographic survey, mapping the fire within the bunker/silo, and suspending coal-feeding operations to the affected area.

Prepare the Area. After the action plan has been developed, the next step is to prepare the area for firefighting operations by neutralizing dusting in the immediate area, ventilating the area, and staging equipment and personnel to prepare to attack the fire.

Extinguish the Fire. After all preparations have been made, firefighting can begin. Monitoring the fire at this stage is key to the success of the effort.

A Final Note

The PRB Coal Users’ Group’s Coal Bunker, Hopper and Silo Fire Protection Guidelines are available in the members’ section of www.prbcoals.com. They are intended for use by personnel with the experience and training required to safely deal with the hazards of coal fires. The guidelines were written by Ed Douberly—president of Utility FPE Group Inc. and a former member of the PRB Coal Users’ Group board of directors. Expertise and peer review were provided by Eric Dorbeck, PE (Consumers Energy); John Ritter, PE (PacifiCorp); Jim Beller, PE and Bob Taylor (AEP); Norm Rockwell (TVA); Jim Coco, PE (Marsh Inc.); and C.E. Wilson (Southern Company).

—Edward B. Douberly is president of Utility FPE Group Inc. A version of this article first appeared in POWER’s October 2003 issue.