TOP PLANT

Melaka: Malaysia’s 2.2-GW Cutting-Edge Combined Cycle Gas Power Plant

The Edra Melaka Power Plant (EMPP), the world’s second GE 9HA.02 gas turbine power plant, is the largest combined cycle gas-fired power plant currently in operation in Malaysia. A POWER Top Plant winner, the project functions as a critical transitional installation that balances the country’s reliability, energy affordability, and sustainability initiatives.

Splash image Courtesy: Edra Power Holdings

Splash image Courtesy: Edra Power Holdings

Sonal Patel

Malaysia has made assertive leaps over the past decade to reshape its domestic energy landscape so that it fits within the palpable shift in the worldwide stance on sustainability, but still reliably shoulders load growth from its burgeoning manufacturing and services economy, and leverages its indigenous gas resources to ensure energy security at affordable prices. Under a recently issued National Energy Transition Roadmap, the Southeast Asian country will phase out almost all of its installed coal power capacity—which comprised 37% of its total mix in 2021—by 2050, with 7 GW expected to be retired by 2033. The country will instead seek to boost its renewables capacity share to 70% (58% of which could be solar PV) by 2050. Recognizing potential supply shortfalls from its rapid pace of coal retirements in the years approaching 2029, Malaysia has recently outlined a gas power build-out that leverages more modern and efficient combined cycle gas turbine (CCGT) power plant technology.

One of the first projects brought online under an approved fast-track generation development plan for Peninsular Malaysia was Southern Power Generation’s 1.4-GW Track 4A (Sultan Ibrahim Power Plant) in Pasir Gudang, a project that won POWER’s 2021 Plant of the Year award for its myriad attributes, including that it showcased the first pair of commercial GE 9HA.02 gas turbines. In February 2022, Edra Melaka Power Plant (EMPP), a three-block 2.2-GW CCGT plant owned by Edra Power Holdings Sdn. Bhd., began commercial operation in Alor Gajah, Melaka State—effectively becoming the world’s second 9HA.02 CCGT project. (A third 1.4-GW 9HA.02 project at Bang Pakong in Thailand has since been completed.)

Critical for Grid Stability

According to Edra, the EMPP was necessary to enhance regional power supply reliability and sustainability. While the Peninsula Malaysia’s southwestern coast is seeing booming economic growth owing to its thriving services, manufacturing, and agricultural sectors, it has faced a “number of retired power plants, as well as having operated several power plants with low-efficient combined cycle power plants, such as E and F gas turbines,” Edra noted. The region has also grappled with “scarcity of fossil fuel availability in addition to the requirements to further limit greenhouse gas (GHG) emission to a single digit,” it said.

At full operation, EMPP generates about 19.6 GWh annually, contributing to about 10% of Peninsular Malaysia’s demand, Edra noted. The massive scale of the plant—each of its three 745-MW single-shaft generating blocks includes a GE 9HA.02 gas turbine, an STF-D650 steam turbine, a W88 generator, and a GE heat recovery steam generator (HRSG)—was also necessary to ensure grid stability and economically competitive power prices. As such a significant contributor to systemwide supply, the plant forms a critical system segment. That’s why the project was designed as “blocks,” Anbarasan Sellappan, deputy chief operation officer at Edra, told POWER. “The system remains reliable with unit-based synchronization.”

Diligent Project Execution Despite Challenges

However, getting the giant plant built required careful project management and diligent execution. Edra, notably, faced a tight schedule dictated by a 2017-signed 21-year power purchase agreement (PPA) secured with Tenaga Nasional Bhd. (TNB), Malaysia’s largest electrical utility. The PPA stipulated a construction period from the notice to proceed (NTP) of 36 months for the first block, 38 months for the second block, and 40 months for the third block, targeting full commercial operation by May 2021. All three blocks ultimately achieved commercial operations consecutively in December 2021, January 2022, and February 2022.

“There was certainly an urgent need to complete the project on time in order to fulfill its PPA obligation to achieve commercial operation within the specified dates,” Edra said. Delays posed liabilities of liquidated damages, it noted. But while the project initially progressed ahead of schedule for two months, “like any other projects around the world, it was unfortunately affected by the COVID-19 pandemic, which has resulted in closure of the project site,” Edra noted. Still, despite the pandemic-related delays, the project “was delivered with agile execution, highest quality standards, and within budget,” it said. “Notably, the power plant has to-date achieved close to 15 million safe man-hours without any lost time injury (since construction commenced),” it stressed.

Edra credits the achievement to “hard work and strong collaborative efforts” by the project’s vast team. Along with Edra’s dedicated project team, consisting of Edra Group Business and Project Development and its Group Operations and Maintenance (O&M), the project was spearheaded by a consortium of Hyundai Engineering, Hyundai Engineering and Construction, and Hyundai Engineering Malaysia Sdn. Bhd., which served as the engineering, procurement, and construction (EPC) contractor. GE served as the original equipment manufacturer (OEM), and Jacobs Engineering Malaysia Sdn. Bhd. was its owner’s engineer. Edra noted it procured EPC and OEM contracts through competitive bids.

Winning Attributes

· The 2,242-MW Edra Melaka Power Plant (EMPP), the world’s second GE 9HA.02 gas turbine power plant, is also the largest in the world using the new technology.

· EMPP, which meets 10% of Peninsular Malaysia’s load, was implemented for critical grid stabilization and efficient, reliable, and affordable power.

· While challenged by the pandemic, the three-block project was successfully completed within budget, a feat achieved through collaboration with a consortium of partners.

· Early integration of an operations and maintenance (O&M) team has ensured seamless O&M after commissioning.

Cutting-Edge Technology

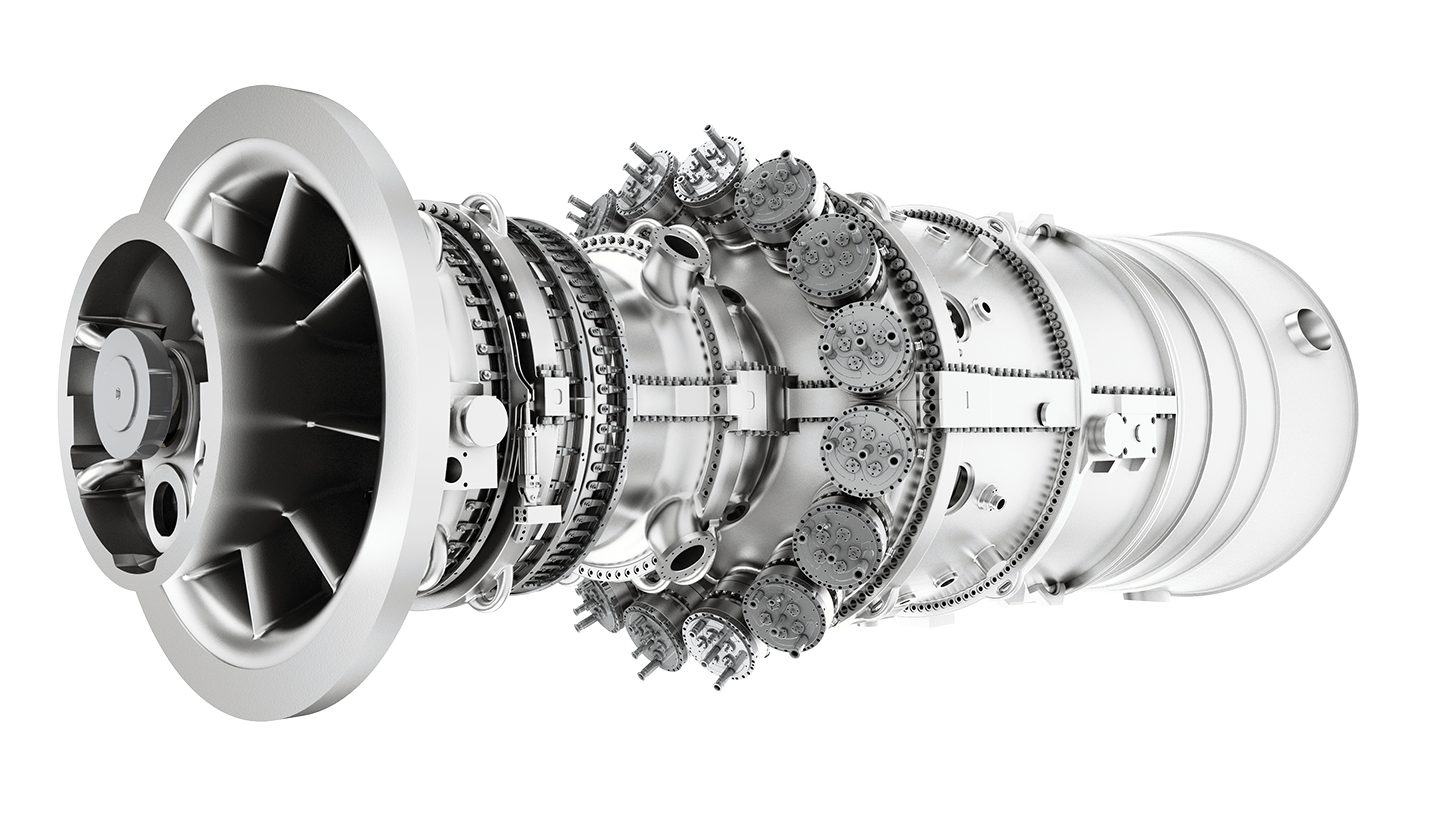

A big draw to select 9HA.02 gas turbines (Figure 1)—though demonstrated only once worldwide at Track 4A—was “GE offered the most competitive offer in terms of technical and commercial aspects,” Anbarasan noted. Crucial for plant performance was that the 9HA.02, rated at 838 MW under International Standards Organization (ISO) conditions, pushes net efficiency beyond 64%.

The technology also offers a hot-mode startup time of less than 30 minutes, a fast ramp rate of up to 88 MW per minute to cater for automatic generation control (AGC) and immediate frequency response to support the grid, and a low turndown to minimum emission-compliance load. According to Edra, the 9HA.02’s standard dry low-NOx (DLN) 2.6e+ combustion capabilities were also well-suited for compliance with Malaysia’s clean air regulations.

As significantly, its flexibility capabilities include a standby and response mode of less than 15% load and hydrogen readiness of up to 50%. At the Melaka plant, prominently, GE’s supplied HRSGs “are designed to provide reliable high-cycling duty due to the innovative single-row harp configuration in the front (hot) end of the HRSG, producing three times less stress than conventional multi-row harps,” the OEM told POWER. The design is tailored for fast starts, rapid response, and low turndown, it said.

1. Three power plants running seven GE’s 9HA.02 high efficiency, air-cooled gas turbines are currently in commercial operation: Track 4A (2021) and Edra Melaka Power Plant (2022) in Malaysia, and Bang Pakong in Thailand (2022). GE says that the HA fleet has reached over 2 million operating hours, and so far, the 9HA.02 fleet has completed more than 100,000 running hours for the seven units in commercial operation plus four units currently in commissioning. Courtesy: GE Vernova

1. Three power plants running seven GE’s 9HA.02 high efficiency, air-cooled gas turbines are currently in commercial operation: Track 4A (2021) and Edra Melaka Power Plant (2022) in Malaysia, and Bang Pakong in Thailand (2022). GE says that the HA fleet has reached over 2 million operating hours, and so far, the 9HA.02 fleet has completed more than 100,000 running hours for the seven units in commercial operation plus four units currently in commissioning. Courtesy: GE Vernova

Finally, the package offered safety integrity level (SIL) protection using the GE Mark VIe distributed control system, providing added safety to the grid system and overall plant safety compliance. GE also offered Edra a holistic solution, including the core power plant equipment, a 21-year service agreement, and digital solutions to manage all project lifecycle aspects. “It’s important to consider specific project requirements and compare the turbines’ capabilities, as different applications may have unique needs,” Edra noted. “GE’s 9HA.02 has gained recognition in the market for its overall efficiency, power output, flexibility, and advanced features.”

Hitting the Road Running

Experience gained from a track record as an IPP with a 5-GW fleet in five countries proved essential for Edra to ensure the smooth execution of the project’s development and construction phases. To meet the tight project timeframe, for example, the Hyundai consortium, Jacobs, and Edra kicked off engineering work before issuance of the NTP, which was issued in December 2017 under a limited NTP. Another prescient decision was that Edra sought to maximize localized supply chains, requiring EPC partners to source equipment, materials, and services from Malaysian subcontractors and suppliers.

Edra also actively involved lenders during project execution to ensure transparency, which resulted in “good financial health” of the project. According to Anbarasan, “Transparency was also integral” in guaranteeing the relatively new technology would function as designed. “Without transparency, there is no collaboration, and with that there are lots of issues [a customer and OEM] can solve together,” he said.

Yet another remarkable aspect of Edra’s project management approach was proactively planning for “manpower competency and proper handover” to minimize O&M gaps. “In a lot of projects, they will have a construction team, and once the plant has been commissioned, there will be a new operations and maintenance team to take over,” he said. “In this project, for the first time, I believe in Malaysia, we had an O&M integrated into the project team,” he said.

The “shadow” team, mainly comprising senior O&M staff, was engaged in the project from its initial construction phase to, for example, “run through all the engineering drawings, the product, and so on,” Edra added. “Once we reached core commissioning, we started adding more people [to the O&M team] to ensure they move with the project with the OEM,” it said. “With the hands-on experience during construction and commissioning phase, and the legacy power plants experience, the team working as part of the project was then converted to the most competent O&M team.”