City of Springfield’s CWLP Dallman 4 Earns POWER’s Highest Honor

City Water, Light & Power (CWLP), the municipal utilities agency of the City of Springfield, Ill., determined that coal-fired generation was its best alternative for providing long-term reliable and economic electricity to the city’s residents. For negotiating an unprecedented agreement with the Sierra Club that allowed the project to move forward, for choosing the latest in coal-fired technology and air quality control systems as the foundation for the city’s comprehensive energy policy, and for assembling a tightly integrated team that completed the project well before the contractual deadline and under budget, CWLP’s Dallman 4 is awarded POWER magazine’s 2009 Plant of the Year award.

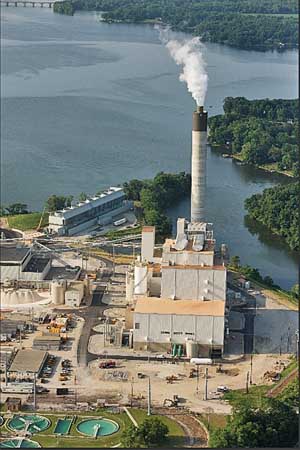

Balancing the need for new electricity generation with aggressive environmental goals frequently results in a high price tag, regardless of which way the scale tips. The price is often short-term pain for long-term gain. Municipal utilities are especially shy of going into debt, which is why much constructive criticism was hurled at City Water, Light, & Power (CWLP) — officially the Office of Public Utilities, City of Springfield — when it announced plans to build Dallman 4 (Figure 1). Many disapproved of the Illinois municipality spending half a billion dollars for a new power plant. But Dallman 4, a 200-MW pulverized coal steam power plant, is a bargain that will pay back Springfield’s residents many times over in the coming years — perfectly balancing the city’s environment goals with reliable and economic electricity supplies.

1. First among equals. City Water, Light & Power of the City of Springfield is completing commissioning of its new 200-MW Dallman Unit 4. The new plant fires Illinois coal and promises to provide a reliable and economic source of electricity for many years to come. Courtesy: CWLP. Photo by Terry Farmer Photography

Unlike some municipal utilities, which routinely draw the ire of ratepayers for high rates and mediocre service, Springfield’s muni is proudly referred to as the "jewel of the city." The construction of Dallman 4 writes another chapter in a success story, with CWLP as the hero for securing the state capital’s power supply while improving the region’s environment and keeping electricity rates low.

Springfield’s mayor recognized that Dallman 4 was going to be a good investment that will keep rates low and system reliability high when he said, "I certainly think [Dallman 4] has raised the expectation for power plants across the United States, and it’s great to have one of the nation’s best practices in coal-fired power plants here in Springfield." It’s unique to find a mayor willing to heap such high praise on an electric utility, but the praise is well-deserved.

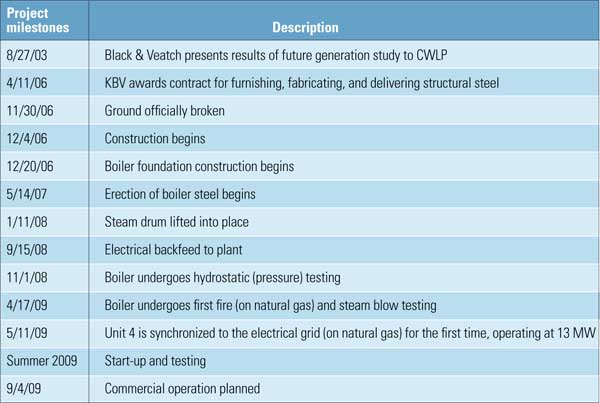

The $515 million project is the most expensive project ever built by Springfield. What’s more, it was completed with minimal cost increases — an impressive feat, especially in today’s construction market. The plant also is entering commercial service approximately six months ahead of schedule (Table 1) and under budget, saving Springfield even more valuable cash just when other cities are looking for ways to increase revenues. CWLP’s general manager, Todd Renfrow, noted that the community is "very proud to soon be the owner of one of the cleanest and most advanced coal-fired power plants in the nation. The execution of the project with little cost overrun and being so far ahead of schedule has raised the bar in power plant design and construction."

Table 1. Actual project schedule. Source: CWLP

Doug Brown, CWLP’s major projects development director and the Dallman Unit 4 project manager, explained that the project’s primary goals included environmental protection and energy efficiency: "A major part of this goal is to protect our ratepayers from the highly volatile market-based rates." Brown mentioned that a secondary goal of the project is "to enhance the knowledge, experience, and reputations for excellence of all the parties involved in the project."

New Power Plant Will Make Economic Sense

Springfield’s requirement for 200 MW of coal-fired capacity was initially identified as part of a long-term planning study conducted in 2001. One goal of the new project was to isolate Springfield from the volatile prices the city was encountering with market electricity purchases when its electricity production capacity couldn’t meet rising demand. Another business opportunity provided by the new plant was to sell surplus power into those same markets, creating a steady source of future revenue.

The target date for completing the new project was set for the end of 2009. Additional engineering studies confirmed the need for the project and refined the cost estimates.

In 2003, Burns & McDonnell was hired by CWLP to be its owner’s engineer and to start the preliminary engineering and permitting phases of the project. In September 2005, the Springfield City Council authorized construction of the project, which was financed through a bond issue and retail rate increases. However, there was one large obstacle looming that effectively stopped issuance of the final construction permits.

Landmark Agreement with Sierra Club

The Sierra Club believed that the air permit limits weren’t aggressive enough and that constructing the new coal-fired plant was only one element of what should be a much more comprehensive energy plan for Springfield. Therefore, it threatened to file suit in order to stall the project. In 2006, CWLP negotiated a landmark agreement with the Sierra Club that allowed Dallman 4 to proceed without any litigation over its air permit.

The original agreement between CWLP and the Sierra Club received national attention when it was announced because it was the first time that a U.S. utility had agreed to cut greenhouse gases and set emission reduction targets under standards of the Kyoto Protocol. Specifically, CWLP agreed to perform four tasks: close its oldest, least efficient coal plant (Lakeside); reduce NOx and SO2 emissions for the remaining plants; invest in renewable energy by purchasing 120 MW of wind power — 60 MW for the City of Springfield and 60 MW for the state government; and increase CWLP’s investment in energy efficiency and conservation projects. In return, the Sierra Club agreed to not contest the air emissions permit for Dallman 4. As part of that agreement, the city and state agreed to share the costs of adding wind power to CWLP’s generation mix by purchasing wind power for 100% of the state capital and about 140 other state government buildings.

CWLP, to its credit, immediately pursued contracts for wind power and entered into two 10-year contracts with NextEra Energy Resources LLC (formerly FPL Energy LLC) for the purchase of 120 MW of wind power. The initial purchase of 20 MW of wind-generated energy, from Hancock County, was made in July 2007; an agreement for 100 MW of wind energy from Crystal Lake was made in November 2008. Both wind generation facilities are located in northern Iowa. Utility officials estimate CWLP’s total wind power purchases over a full year will produce enough renewable energy to supply the equivalent of about 18% of CWLP’s electricity supply requirements. In 2008, wind purchases equaled 4.57% of net generation at an average price of $43.09/MWh.

"I’ve waited so long for this day," CWLP’s Renfrow told the city council utilities committee in early May of this year, noting that he had struggled to conclude an agreement with the state under former Governor Rod Blagojevich’s administration, but had been successful working with Governor Pat Quinn. The renewable energy purchase agreement is retroactive to July 1, 2008, and runs through June 30, 2018. The state will pay about $19.30/MWh as a surcharge on metered electricity for the wind power; the surcharge will increase 4% per year for the term of the contract. In return, Springfield will invest up to $1.86 million in energy conservation and efficiency programs in the same state buildings though 2015. This agreement with Illinois allowed the City of Springfield to tick off two of the four Sierra Club requirements.

CWLP’s Generation Portfolio

Before the new unit was built, CWLP’s generating capacity was provided by three coal-fired steam turbine generators at Dallman (372 MW), one dual-fuel natural gas – and oil-fired combustion turbine (128 MW), two oil-fired combustion turbines (totaling 38 MW), three oil-fired diesel generating units (totaling 6 MW), and two coal-fired Lakeside units (76 MW total). CWLP’s total summer maximum net generating capability was 620 MW before adding Dallman 4’s contribution and subtracting the recently decommissioned Lakeside units.

The two 1960s-vintage units at the adjacent Lakeside Power Station were shuttered with the completion of Dallman 4 (which also sits adjacent to the existing Dallman units) as part of the Sierra Club agreement. Lakeside Power Station was CWLP’s original generating facility, constructed in the mid-1930s on the shore of the utility’s then-new manmade Lake Springfield. By the mid-1960s, Lakeside consisted of eight coal-fired boilers and seven turbine-generators, only two of which — boilers 7 and 8 and turbine units 6 and 7 — were operating when the plant was shut down.

Dallman consists of Dallman 31, an 86-MW unit installed in 1968; the 87-MW Unit 32, installed in 1972; and the 199-MW Unit 33, placed into service in 1978. In spite of being decades old, these units continue to operate economically. In fact, in 2008, the existing Dallman station’s net fuel cost was $19.87 per MWh. All of the Dallman units are designed to burn 100% Illinois high-sulfur coal with an approximate heat content of 10,500 Btu per pound. Coal for all the units is trucked from the Viper Mine in Elkhart, Ill., to the coal-receiving yard for both Dallman plants.

Particulate emissions from the existing Dallman units are controlled by electrostatic precipitators. In addition, the Dallman units are equipped with wet scrubbers to control SO2 emissions. The scrubber for Dallman Unit 33 was installed in 1980; a second scrubber, serving the two older units, was put into operation in June 2001.

Each of the Dallman units has also been equipped with a selective catalytic reduction (SCR) system placed in service in May 2003, which operates during the entire year. All three Dallman units use once-through condenser cooling water from Lake Springfield.

Becoming Energy Self-Sufficient

In 2008, CWLP generated about 1.752 million MWh and purchased 410 thousand MWh for total consumption of 2.163 million MWh. CWLP’s summer peak demand of 420 MW was set on Monday, August 4 at 5 p.m., outstripping the economic production capacity of the existing plants and requiring market electricity purchases. With the addition of Dallman 4, CWLP will be able to easily meet Springfield’s summer peak demand and still have plenty of capacity available to sell into the electricity market.

Not only does Springfield no longer need to purchase expensive electricity from the open market, but it also now could very well be one of the lower-priced suppliers in that market. The foresight of CWLP and city leaders in building in that extra capacity will literally pay dividends to Springfield’s residents for many years to come.

The 200-MW net Dallman 4 project is a prime example of technological advancement and innovation that works in concert with Springfield residents’ keen desire to be environmentally progressive. Dallman 4 satisfies those desires by being one of the cleanest subcritical pulverized coal units in the nation. Its flue gas cleaning processes will remove 99% of the SO2, 95% of the NOx formed when burning high-sulfur Illinois coal, as well as 90% of the mercury in the stack gas. Carbon emissions are also reduced because Dallman 4 is 34% more efficient than the Lakeside units it replaced and shuttered in April.

The design specs of Dallman 4 also send the message that Springfield is dedicated to buying locally whenever possible. The plant burns high-sulfur Illinois coal — going against the grain of most other new coal-fired plants, which routinely select Powder River Basin coal.

State-of-the-Art Environmental Protection

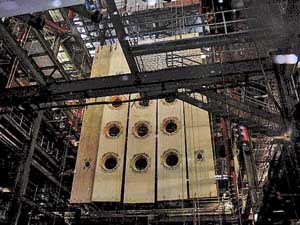

KBV Springfield Power Partners (KBV) — the project’s engineering, procurement, and construction (EPC) contractor — purchased a Foster Wheeler boiler (Figure 2), a Toshiba steam turbine generator (Figure 3), and Wheelabrator Air Pollution Control Inc. (a wholly owned subsidiary of Siemens Power Generation) air quality control system (AQCS) equipment. Emissions control at Dallman begins with Foster Wheeler’s Vortex series of split-flame, low-NOx burners in the boiler before the combustion gases pass to a substantial lineup of AQCS equipment (Figure 4).

2. Raise the drum slowly. One of the heaviest and most challenging lifts in the course of constructing a power plant is raising and positioning the steam drum. The complete steam generator was sourced from Foster Wheeler. Courtesy: CWLP

3. Power to the people. A Toshiba steam turbine configured with a combined high- and intermediate-pressure casing couple with a single double-flow low-pressure section provides shaft horsepower to the generator. Courtesy: CWLP

4. Lean and clean. The Foster Wheeler steam generator is configured with low-NOx burners that reduce NOx produced during combustion. A selective catalytic reduction system will reduce NOx levels in the flue gas to meet the plant’s permit limit. Courtesy: CWLP

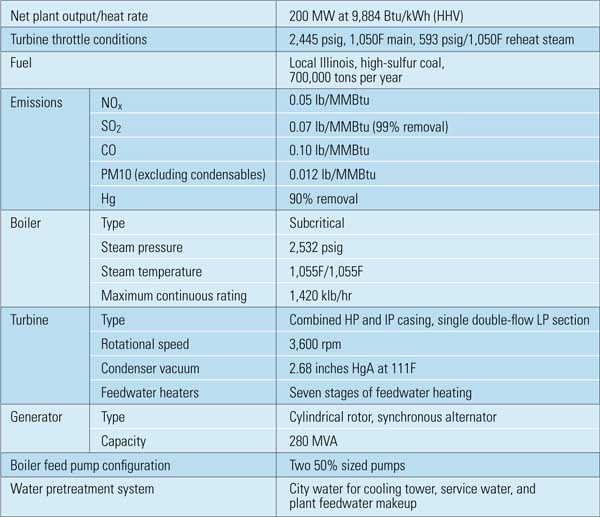

Downstream of the boiler, an SCR further reduces the NOx concentration in the stack gas. Next up is a powder-activated carbon injection system that is used for mercury removal. A fabric filter, a wet flue gas desulfurization (FGD) system for the removal of SO2 from the stack gas, and wet electrostatic precipitator (WESP) to remove acid mist and ultra-fine particulate from the flue gas complete the emission reduction equipment. Siemens provided its first U.S. utility-scale WESP to ensure the facility meets its permitted emissions. The boiler island is also equipped with Foster Wheeler’s MBF coal mills. Table 2 summarizes many of the plant’s key performance parameters.

Table 2. Key Dallman 4 performance parameters. Source: CWLP

Instead of once-through lake cooling water, the plant uses a state-of-the-art plume-abated cooling tower, which will significantly reduce the chance of developing fogging conditions over the adjacent I-55 highway.

Coal ash disposal is subcontracted, and ash will be delivered to an abandoned mine located near the plant. The cost of ash disposal is $9.50 per ton for 2009, rising to $11/ton in 2011.

President Lincoln — a Springfield lawyer who rose to national prominence by representing Illinois in Congress before becoming president — may have been tall, but Dallman has him beat. At 440 feet, the new Dallman 4 stack is the second-tallest structure in Springfield, overlooked only by a Dallman 3 stack (Figure 5). Third runner-up is the combined stack for the first two units at Dallman. The State Capitol comes in a distant fourth.

5. The air is rare up there. The new Dallman 4 stack is the second-highest landmark in the City of Springfield and is higher than the State Capitol building. Courtesy: CWLP

That isn’t to say construction of the stack was easy. As Black & Veatch Vice President and Project Manager Les Rinck tells the story, volatile commodity prices and a tight subcontractor market put a lot of pressure on the team when bids came in way over budget. The bids received for construction of the stack were two to three times the original estimates, so KBV elected to self-perform the task, although neither company in the KBV joint venture had ever erected a stack before. However, they did have extensive experience in slip forming large concrete structures. A consultant from Austria assisted KBV in the planning and execution of the concrete shell slip forming operation. Tri-Clor Inc. was selected to provide detailed design and fabrication of the fiberglass stack liner and perform the erection with KBV. Tri-Clor also had no prior experience building a power plant stack liner — its expertise was in large fiberglass pipe and vessels. At the end of the day, construction of the concrete Dallman 4 chimney shell using slip form technology with a fiberglass liner was completed on schedule in only 28 days and 3 hours. The total cost of the stack and liner ended up being only 20% above the original estimate.

Emerson’s Ovation control system will monitor and control the new unit’s Foster Wheeler pulverized coal – fired boiler, as well as the burner management system, bottom ash handling, combustion control system, coal-handling system, and FGD and SCR systems (Figure 6). The Ovation system also interfaces with the Toshiba steam turbine controls. Emerson’s PlantWeb digital automation solution utilizes high-speed communications networks, intelligent field devices, and bus I/O technologies to increase plant operating efficiency and reduce long-term operation and maintenance (O&M) expenses. In all, Ovation will manage 2,500 hard I/O points and 2,500 soft I/O points. The controls were engineered and installed by the Power & Water Solutions division of Emerson.

6. The master controller. Emerson’s Ovation DCS system automates the plant’s many control tasks over a high-speed communication network. Courtesy: CWLP

"Dallman Unit 4 is being designed and built with efficiency and environmental stewardship in mind," said Brown, pointing out that, when completed, the new unit is expected to cost approximately 20% less to operate per megawatt-hour than the most efficient of the three existing Dallman units. "Emerson’s integrated digital automation system is a comprehensive solution that will not only contribute to improved operational efficiency and reduced costs, but will also support our utility-wide commitment to protecting the environment."

The Keys to Success

Dallman 4 is expected to perform its final acceptance tests about August 31. CWLP will take ownership of the plant at the successful completion of all plant acceptance tests — including those of the AQCS equipment — and certification of the test results. Final acceptance of Dallman 4 should occur in September 2009 — months prior to the April 2010 completion date that the project schedule required.

From CWLP’s perspective, one of the keys to the success of this project was picking the right team to design and build Dallman 4 (Figure 7). Early in 2005, Kiewit Power Constructors Co. and Black & Veatch Corp. formed a joint venture known as KBV Springfield Power Partners, the design/build team to construct Dallman 4. Black & Veatch provided the engineering design, procurement of major equipment, and start-up; Kiewit was the primary contractor for construction of the facility. Glenn Miltenberger, the KBV project manager, also noted that the Kiewit construction staff was relatively young. Even though the average age was about 30, the staff was very dedicated and motivated, which led to the project’s success.

7. Dream team. The project team celebrated the successful start-up of Dallman 4 with a June 26 reception. Courtesy: CWLP. Photo by Terry Farmer Photography

The second key to the project’s success was the quality of the craft labor. Central Illinois Building and Construction Trades Council and the Basic Crafts Council of Mid-Central Illinois supplied the project with skilled craft labor. Teamwork did not stop with KBV and CWLP; it included developing a successful relationship between KBV management and craft labor. The labor leadership was able to supply experienced craft labor during the tight labor market that existed during the peak of construction.

The third key to the project’s success was the negotiation of an EPC contract that locked in 2005 prices for materials and leveraged KBV’s efficiency in managing the overall project. These may have been the most important of the thousands of decisions that were required of CWLP over the next four years.

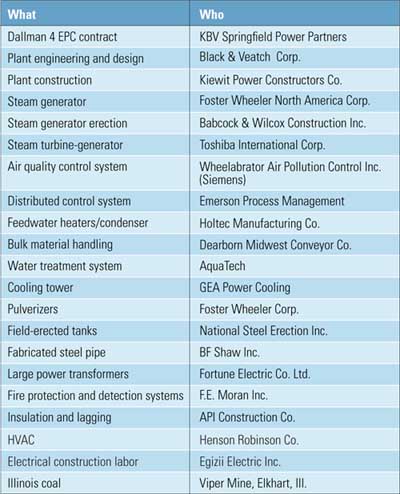

Other major contractors and equipment suppliers are listed in Table 3.

Table 3. Major contractors and equipment suppliers to CWLP Dallman Unit 4. Source: CWLP

As expected, the project team encountered and overcame numerous obstacles and challenges during the design and construction of Dallman 4. The first, and perhaps largest, management challenge was determining the right course of action when the facility’s air permit, scheduled for release in early 2006, was delayed until December 2006 when the Sierra Club intervened in the process. The technical challenge was to improve the design of the AQCS to meet even tighter emissions standards that were a result of the Sierra Club agreement at a point when project engineering and procurement were more than 50% complete. Compounding the schedule problems, KBV already had mobilized key construction personnel, a substantial amount of equipment had been delivered to the site, and the team was ready to begin construction when issuance of the air permit was delayed.

Rather than lose even more time due to the air permit delay, CWLP took the bold step of instructing KBV to continue with the design and purchasing of AQCS and other long-lead-time equipment while waiting for the air permit. Although very risky at the time, the decision to release KBV was, in retrospect, perhaps the best single decision CWLP made on the entire project. The effect of this decision was to keep engineering and procurement well ahead of construction and to moderate the substantial material commodity cost increases that were plaguing the construction industry at the time. Having the major engineering equipment on site during steel erection also helped accelerate the construction schedule.

By the time construction was allowed to begin, key field personnel were all well acquainted and very familiar with their respective responsibilities. The closeness of the workforce allowed personnel to immediately address — and correct, if necessary — issues identified in the field without additional costs to the owner or the contractor. Having both engineering and procurement well ahead of the actual construction schedule also provided time for detailed drawing reviews and, with the equipment on hand, many constructability issues were eliminated before they became field issues.

The People Who Powered the Project

In many cases, an EPC contract means the owner has little control over final plant design and construction. "We’ll give you the key when we’re done" is the EPC contractor’s attitude. Not so with KBV, which worked with CWLP just as though its people were on the CWLP payroll. Miltenberger was complimentary of the CWLP project team for "embracing the partnering approach to managing the project. It knocked down a lot of barriers" that would otherwise have slowed progress.

CWLP was kept informed of every aspect of the project, and its people were expected at the daily safety and scheduling meetings, weekly quality and status meetings, monthly management meetings, and quarterly partnering meetings. Keeping CWLP involved in every aspect of the project helped maintain open communications among all the project participants and made possible a true open-door policy for everyone. This sort of organizational openness doesn’t eliminate the challenges that are inevitable on a project of this magnitude. But open communications made discussion and resolution of many challenges possible before those challenges became major issues that had to be passed up the organizational hierarchy for resolution. According to Brown, "It cannot be emphasized enough that the entire project was operated as a team with as much priority placed on the customer’s needs as was placed on the contractor’s profitability."

The plant’s operational plan is also strong. CWLP is fully staffed, and its people are well-trained and ready to assume O&M responsibility for Dallman 4 when final acceptance is achieved.

All of Springfield’s power plants are located within walking distance of each other, and this close proximity helped solve many staffing issues. A site generation director manages O&M resources for all the generating facilities.

Closure of the Lakeside facility freed up experienced O&M technicians for Dallman 4. Reporting to the generation director is a single maintenance superintendent, who is able to allocate maintenance resources as required. Also reporting to the generation director are two superintendents of operations, one for the three existing Dallman units and one for Dallman 4. Dallman 4 is staffed with five operators per shift, but a single shift supervisor covers all four coal-fired units. A recent poll of operators found that their preference remains eight-hour shifts, so CWLP uses a 5 x 8-hour schedule.

New jobs created by Dallman 4 turned out to be evenly filled by promotions, transfers, and new hires. Dallman 4 opened 24 new job opportunities; 12 were filled from within CWLP from the existing Dallman units. Those 12 jobs were then backfilled by 12 new hires. The remaining 12 new jobs were then advertised and hires were made from outside of CWLP. Interestingly, the same union local that represents some of the CWLP operators at the existing Dallman units (International Union of Operating Engineers) decided to go with a different agreement for the 24-member operating staff of Dallman 4. That new agreement is currently being negotiated.

Pay for Performance

Throughout the project KBV has been able to successfully meet or beat the project milestone dates. Groundbreaking was on November 30, 2006, and steam blow was completed 29 months later, on April 17, 2009. The unit was synchronized on May 11, 2009 — many months ahead of the planned project schedule of January 12, 2010. Start-up and testing will take place over the summer; commercial operation is slated for September 4, 2009, fewer than 36 months after groundbreaking. "It’s unheard of to be this far ahead of schedule and on budget," said Brown, the project manager.

This excellent performance enabled the plant to generate more than 5 MWh before June 1, which earned KBV a power production bonus, the first of two power production performance bonuses.

During the later stages of start-up, CWLP recognized the value that the intermittent electric generation was providing Springfield by offsetting expensive purchased power. As any city with an entrepreneurial spirit would do, it cut a deal with KBV: If KBV could schedule the generation of power during the on-peak hours of 7 a.m. to 10 p.m. from June 1 to September 18, 2009, and perform required maintenance as much as possible during off-peak hours, then a second power production bonus would be made available. Weekday generation is credited with 100% of the on-peak generation and weekends are credited at a rate of 50% of the on-peak generation. For each block of 5,000 MWh generated, KBV is awarded a bonus. The bonus rate for each block of 5,000 MWh is fixed for each month of the incentive period.

This is an excellent approach to motivating an EPC contractor to accelerate a schedule that benefits both the owner and the contractor.

The success of this project in the eyes of city residents has a single measure: electricity rates. Even after rate increases totaling about 33% over the past three years to pay for Dallman 4, CWLP rates are described as still being among the lowest in the state, and they are modest compared with rates in other parts of the country. For example, the current regular residential rates are $0.0706/kWh winter and $0.0851/kWh summer. Large commercial/industrial rates also remain very attractive, with a summer energy charge of 0.0509/kWh with a $13.97 demand charge and a $550 monthly customer charge.

"This is something the people of Springfield should be very proud of," said former Assistant General Manager Jay Bartlett. "We’ve taken our future, in terms of the energy crisis, and we’ve taken control of it."

Cool City Certification

Leveraging CWLP’s agreement with the Sierra Club, Springfield became a "Cool City" in August 2008 by ratifying the U.S. Mayors’ Climate Protection Agreement, whose goal is to reduce greenhouse gases 7% below 1990 levels by 2012. Springfield’s stated goal is to become one of the top 10 greenest cities in America, and building the coal-fired Dallman 4 brought the city a big step closer to making that goal a reality.

With Dallman’s contribution plus the purchase of 120 MW of wind capacity, energy conservation initiatives, closing of the Lakeside units, improved generating efficiency, and emissions reduction projects completed at each of the three existing Dallman units, CWLP’s carbon dioxide emissions for its native load customers will be lowered to 1990 levels by 2015. That’s a goal the Midwest hopes to attain by 2020, as stated in the Midwestern Greenhouse Gas Reduction Accord signed in fall 2007.

Springfield has shown the power industry that building a coal-fired power plant as part of a comprehensive energy plan can be very cool. Congratulations to CWLP, the City of Springfield, and the rest of the project team for a job well done.

—Dr. Robert Peltier, PE is POWER‘s editor-in-chief.