CFB Scrubbing: A Flexible Multipollutant Technology

The number of regulated air emission constituents is increasing while the acceptable amounts for release are decreasing. In the long run, picking the most flexible multipollutant technology is surely the least cost option.

Emission limits for conventional pollutants emitted from power plants—particularly SO2, NOx, and particulate matter—continue to tighten around the globe. In the U.S., the Cross-State Air Pollution Rule, although vacated in August 2012, will likely be reworked and eventually promulgated, mandating additional SO2 reductions. Consequently, plant owners must continue to evaluate the costs and benefits of adding a back-end air quality control system (AQCS) against shutting down noncompliant units. The timing of rule changes makes this a very difficult evaluation.

The North American Electric Reliability Corp., responsible for the bulk power system reliability, has spoken often about the impact of increasingly restrictive emissions regulations on the reliability of the U.S. power delivery infrastructure. In effect, the debate centers on balancing lower emissions limits with the effect on system reliability of excessive coal plant retirements.

This discussion is not limited to the U.S. Europe’s new Industrial Emission Directive (IED) has tightened both SOx and NOx emission limits by 50 mg/Nm3 and particulate limits by 10 mg/Nm3 compared to the prior large combustion plant directive. And last year, China lowered its SOx, NOx, and particulate limits for power plants to levels even lower than those in Europe’s IED.

New constituents are also being added to the U.S. regulatory milieu, such as metals, acid gases, and organic compounds rolled under Mercury and Air Toxics Standards rules. Europe is not far behind, with the IED now also requiring a best available technology standard for these constituents. These constituents have always been regulated for certain waste fuel applications, such as waste-to-energy plants and incinerators, but now regulators have set limits for all boilers, including large utility coal boilers.

Plant owners are being asked to make billion-dollar AQCS purchase decisions when the regulations are in flux and court oversight is uncertain. In this era of regulatory ambiguity, selecting the most flexible AQCS design is surely the prudent decision.

A Better Way to Clean Flue Gases

In the past, due to its proven large scale and high ability to capture SO2 over a wide range of fuel sulfur levels, wet flue gas desulfurization (WFGD) scrubbing technology was the most popular choice for removing sulfur from boiler flue gases in large power plants and industrial facilities. WFGD technology has a low operating cost because it utilizes low-cost limestone as the reagent and can produce gypsum for sale to wallboard manufacturers, if there is a local market. However, on the downside, a WFGD system is expensive to build, uses the most water, occupies the largest amount of real estate, and can keep a full crew busy maintaining its large number of pumps, pipes, valves, and vessels. But more importantly, due to its chemistry and process, a WFGD system is only marginal for capturing metals, including mercury, or acid gases such as SO3, HCl, or HF.

Now with U.S. regulations requiring capture of mercury, acid gases, dioxins, and furans, in addition to SO2 and particulates, other FGD technologies are becoming more popular due to their ability to capture this expanded set of pollutants. There are different types of technologies, ranging from simple injection of a sorbent into the boiler flue gas (direct sorbent injection) to the more established spray dryer absorber (SDA) technology (which sprays a fine dry mist of lime into the flue gas), to newer circulating fluidized bed (CFB) technology, which circulates the boiler ash and lime between an absorber reactor and fabric filter.

These different FGD technologies have their pros and cons, but for many midsize to large power and industrial facilities, CFB scrubbers are growing in popularity. This is most evident in the pipeline of U.S. retrofit scrubber projects, where more and more projects are selecting CFB technology.

In the past, these alternative scrubbing technologies were typically chosen over wet FGD technology for their much lower capital cost and water usage, provided that the boiler size was not too large and the fuel sulfur level was not too high. Today, CFB scrubber technology has broken through these limitations with single-unit designs up to 700 MWe backed by operating references on coal power plants of over 500 MWe and on fuels with sulfur levels above 4%. CFB scrubber technology has now stepped out in front of other technologies due to five key advantages:

- High multipollutant capture capability

- Low installed cost

- Low water use

- Large scale

- Wide fuel sulfur flexibility

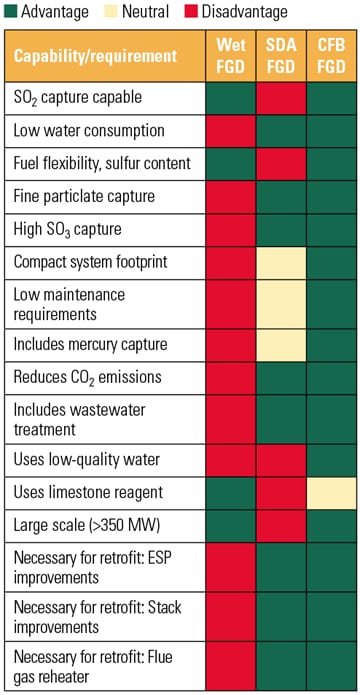

As summarized in Figure 1, CFB scrubbers also offer other benefits, including low maintenance cost, compact footprint, and the flexibility to use low-quality lime and water. One key process advantage of a CFB scrubber, unlike SDA technology, is that the flue gas temperature does not limit the amount of lime injection. This feature allows a significant increase in acid gas scrubbing performance.

|

| 1. Many scrubbing options. Foster Wheeler proposes that circulating fluidized bed (CFB) scrubbing is superior to wet flue gas desulfurization (FGD) and spray dryer absorber (SDA) FGD technologies. Source: Foster Wheeler Global Power Group |

CFB scrubbing technology offered by Foster Wheeler utilizes advanced CFB scrubber technology, which efficiently and economically captures a wide array of pollutants—such as SO2, particulate matter, acid gases, and organic compounds—while utilizing the least amount of water, a vital resource.

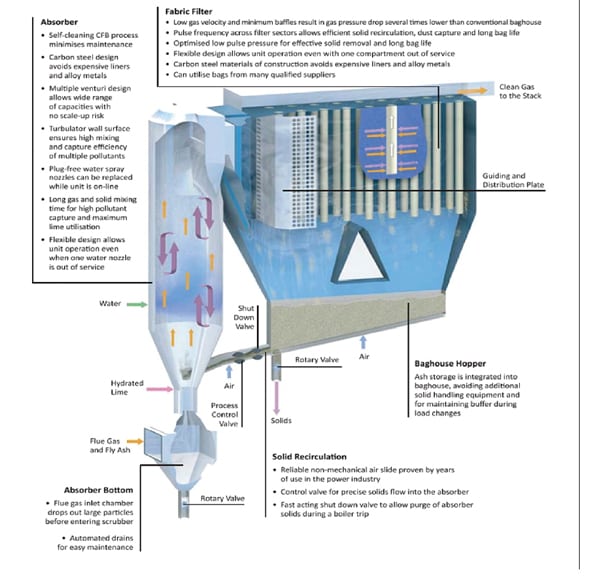

The multipollutant CFB scrubber is a flexible and economical technology capable of removing a wide array of pollutants from flue gases of nearly any combustion or industrial process. As shown in Figure 2, boiler flue gas enters at the bottom of the CFB scrubber’s upflow absorber vessel. The gas mixes with hydrated lime and water injected into the absorber, as well as recirculated solids from the downstream fabric filter. The turbulator wall surface of the absorber causes high turbulent mixing of the flue gas, solids, and water to achieve high capture efficiency of the vapor phase acid gases and metals contained within the flue gas.

|

| 2. Follow the gas. This schematic depicts the CFB scrubber process. Courtesy: Foster Wheeler Global Power Group |

High Reliability by Design

CFB scrubbing technology incorporates a number of built-in features to maximize reliability. The absorber vessel is a self-cleaning upflow reactor. Water injection nozzles, located on the perimeter of the absorber above the introduction points for the recirculated and sorbent solids, provide an atomized spray cloud of water droplets.

These nozzles must be removed periodically for replacement of wear components. However, the entire perimeter of the CFB absorber vessel is used to locate the water nozzles, thus additional nozzle locations are typically available to allow installation of a spare nozzle prior to removing an operating nozzle for inspection or maintenance. Operators can switch to a spare nozzle without shutting down the unit.

The multicompartment baghouse lends itself to online replacement of filter bags with one compartment off-line. Multiple multicompartment fabric filter baghouses are located above the absorber vessel to allow recirculation of particulate solids. Separate compartments are each lockable on the flue gas side for maintenance purposes; thus, it is possible to shut down one compartment for maintenance while running the remaining compartments with 100% boiler flue gas flow. The baghouse hoppers serve as temporary storage bins for the large portion of material that is fed into the solids-recycling system.

The Largest CFB Scrubber in the World

In June 2011, a 520-MW coal power plant at Basin Electric’s Dry Fork station (Figure 3) went online in Gillette, Wyoming. (Due to its 4,430-foot site elevation, the actual net output of the Dry Fork plant is rated at 420 MW.) Behind its pulverized coal boiler sits the largest CFB scrubber operating in the world today.

|

| 3. Go big or go home. The world’s largest CFB scrubber is found at Basin Electric Dry Fork Unit 1. Courtesy: Basin Electric Co-Op and Wyoming Municipal Power Agency |

During the project planning phase, Basin Electric hired Sargent and Lundy to evaluate and recommend a FGD technology based on the criteria of achieving strict emission limits while delivering the best economics and reliability. After months of study and evaluation, Sargent and Lundy recommended the CFB scrubber technology that was ultimately selected by Basin Electric.

Since it has gone online, the CFB scrubber has demonstrated a very high, 98% availability while meeting all the strict emission requirements set by the U.S. Environmental Protection Agency and the state of Wyoming. The emission regulations are designed to directly or indirectly limit a broad array of compounds designated as pollutants such as SO2, SO3, HCl, H2SO4, HF, PM10, PM2.5, mercury, and other heavy metals.

The CFB scrubber has exceeded its design performance, reducing SOx by 95% to 98%, to levels below 0.06 lb/MMBtu (50 to 60 mg/Nm³). It also passed a 30-day mercury removal compliance test by meeting the permitted emission limit of 20 lb/TWh (2.35µg/m3) while demonstrating a mercury removal rate in excess of 95%.

In addition, the CFB scrubber provided other key benefits to the Basin Electric Dry Fork project such as reducing the scrubber’s water requirement by 30% and real estate by 80% compared to WFGD technology. In addition, the scrubber ash is being used to fill and stabilize a nearby open pit coal mine.

— Robert Giglio ([email protected]) is vice president of strategic planning and market analysis for the Foster Wheeler Global Power Group.