WILMINGTON, North Carolina (May 22, 2018) — Global Nuclear Fuel (GNF) today announced that it has been awarded a long-term contract by Entergy Nuclear to continue to fuel its boiling…

Nuclear

Nuclear power plant design, licensing, construction, operation and maintenance, refueling, and uprating.

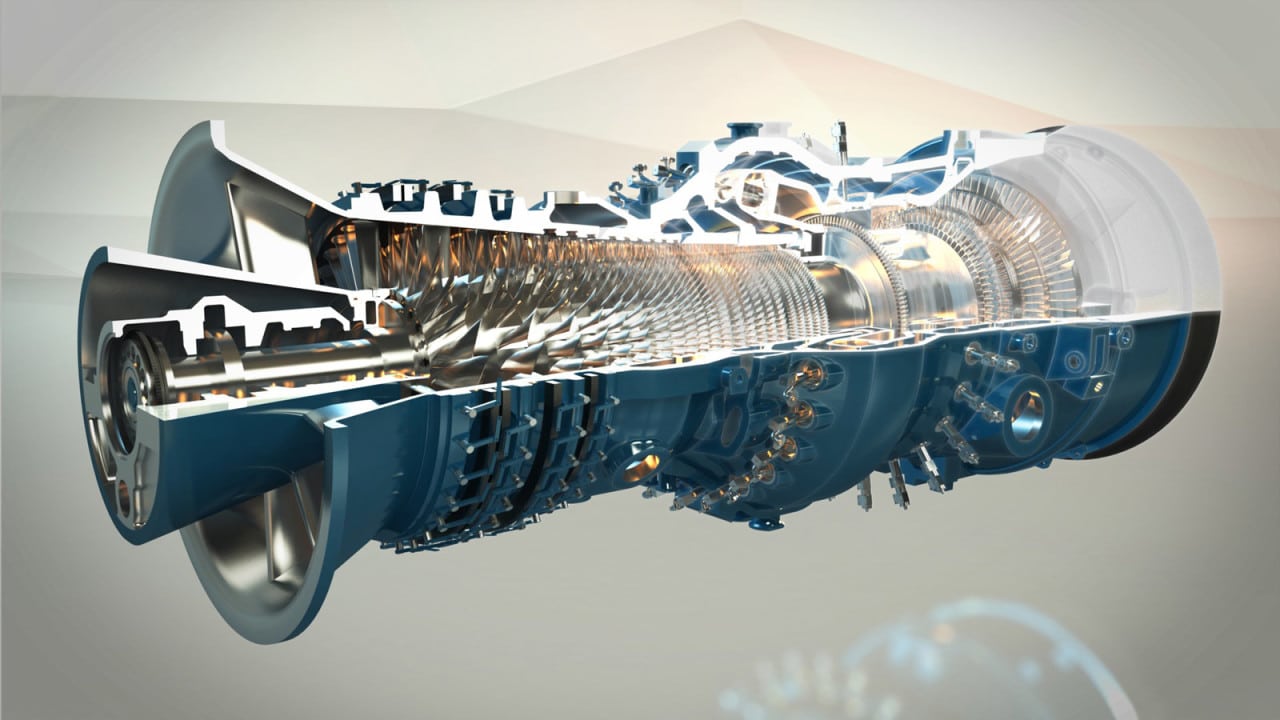

NTE Energy on May 21 inaugurated the new Middletown Energy Center in Middletown, Ohio, the latest in a series of natural gas-fired power plants the Florida-based company is developing in…

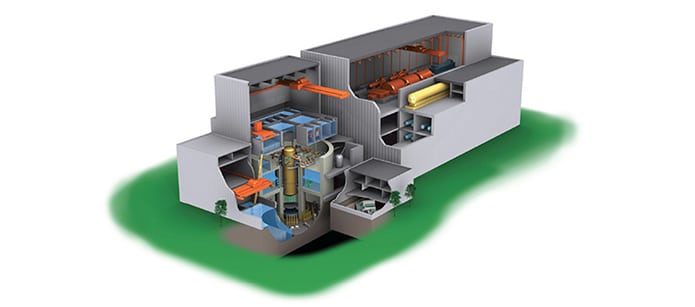

Dominion Energy will provide seed money to further work of GE Hitachi Nuclear Energy’s (GEH’s) BWRX-300, a 300-MWe small modular reactor design (SMR). Dominion has “no plan at this time…

(MAY 17, 2018) —Framatome signed a multimillion-dollar contract with Dominion Energy to provide steam generator services to the company’s entire nuclear reactor fleet. Scheduled to take place during eight outages…

Global demand for power and water is accelerating—and the Middle East is no exception. A burgeoning population combined with multiple industrial diversification programs is fueling a boom in power and…

GE will buy Alstom’s stakes in three energy joint ventures (JVs) the companies formed when GE acquired Alstom’s energy business nearly three years ago. Alstom and GE on May 4…

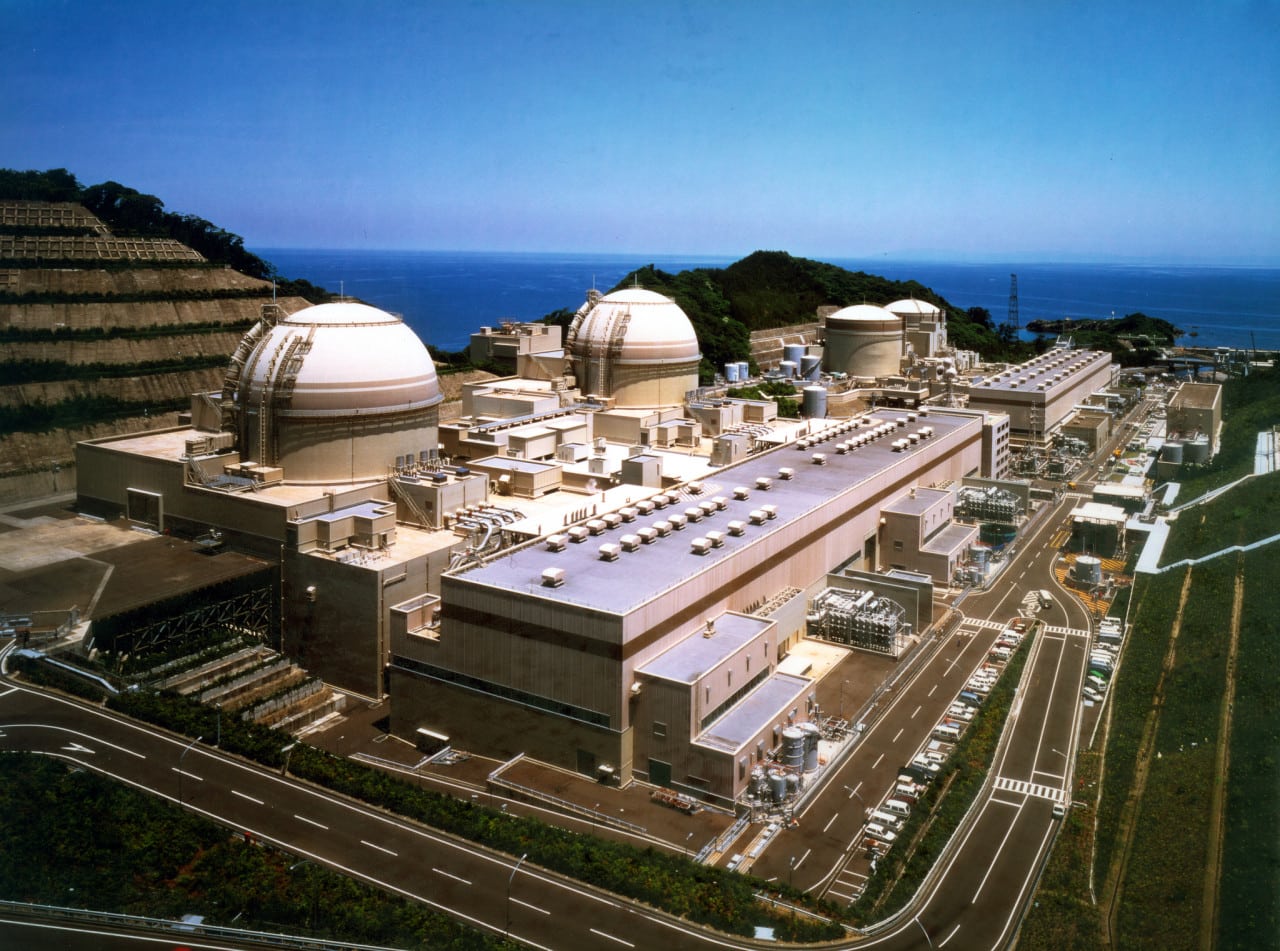

Unit 4 of Japan’s Ohi nuclear power plant is online again, the eighth reactor in the country to resume service after the Fukushima disaster in 2011. Japan idled all 50…

A report from Bloomberg New Energy Finance (BNEF) says the financial struggles of U.S. nuclear power plants continue to increase, and it is likely more plants will be faced with…

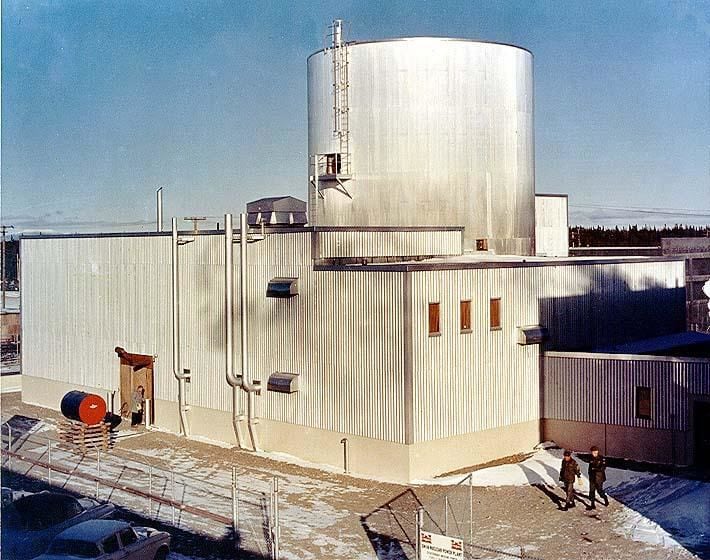

It’s been nearly 50 years since Alaska’s only nuclear power plant was in service. Nonetheless, the site has continued to be a hub of activity off and on over the…

The U.S. Department of Energy (DOE) wants to know whether small-scale, modular coal-fired power plants are feasible. The DOE this week put out a request for information on how to…