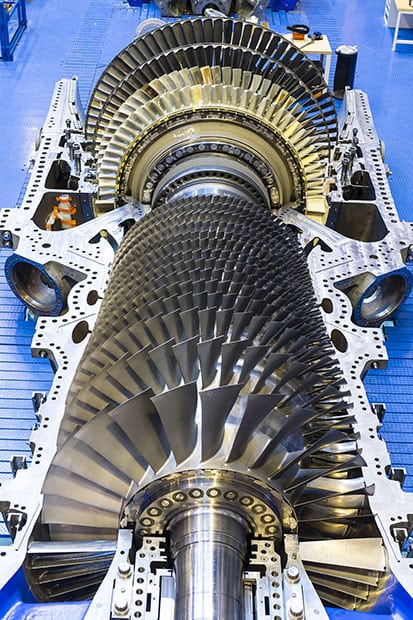

Siemens Energy Implements 3D Virtual Maintenance Trainers for Large-Scale Gas Turbine Power Plant Technology Orlando, FL (February 14, 2018) – The DiSTI Corporation, the world’s leading provider of 3D virtual…

Gas

Coverage of every aspect of gas-fired power plant design, construction, and O&M, including combined cycles, HRSGs, cogeneration, and LNG.

Mulheim, Germany – EthosEnergy has been awarded a rotor exchange contract at a combined cycle power plant in Germany. The contract is for the supply of one fully refurbished GE…

25 MW pilot power plant will utilize Isopentane gas as a fuel source New plant will add equivalent power needed to supply more than 100.000 Ghanaian homes TM2500 proven technology…

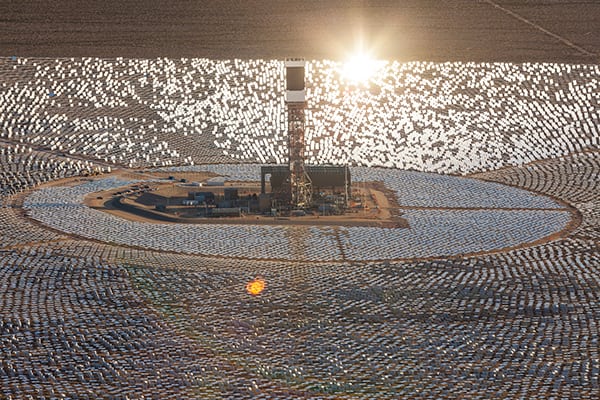

Commentary The clean energy industry was hit hard by two decisions coming out of the Trump administration these past few weeks. First, a 30% tariff was imposed on imported solar panels. Then earlier…

The Trump administration’s fiscal year 2019 budget request released February 12 asks for more money to support fossil fuel-based power systems, but seeks funding below current levels for other energy…

The budget bill passed by Congress and signed by President Trump in the early hours of February 9 extends a host of tax credits for energy technologies, including provisions to…

The number of gas turbines operating around the world is growing steadily. In this environment, the number of power sector workers new to gas turbines is also expanding, and a…

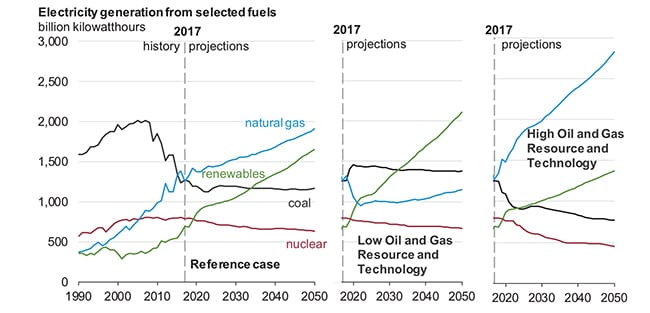

After decades of lethargic power demand—and negative growth in 2017—U.S. electricity use is expected to grow steadily through 2050, driven by a healthy economy and increasing efficiency, the U.S. Energy…

NRG Energy, in a bid to shed $7 billion in consolidated debt, is selling the bulk of its renewable assets and development platforms along with several coal and natural gas…

Shareholders of Mississippi Power will have to absorb the majority of outstanding costs resulting from the scuttled Kemper County coal gasification project, as the state’s Public Service Commission (PSC) on…